As global AI server investment accelerates, the demand for 1.6 Tbps transmission speeds by 2026 is pushing PCB standards into the M9 era. This shift moves beyond M7/M8 specs, triggering a total supply chain upgrade. Once viewed as mere consumables, PCB drill bits are now strategic materials that directly determine yield and signal integrity in advanced AI production.

●M9 Substrates: High Performance, High Difficulty

M9-grade substrates must achieve the "three lows": Low Dk (dielectric constant), Low Df (loss), and Low CTE (thermal expansion). While essential for high-frequency signal integrity, these properties increase material hardness and density. This makes machining exceptionally difficult; while a standard PCB allows 10,000 holes per drill, M9 substrates can reduce tool life to just 200 holes.

●Q-glass: Pushing Drilling to the Limit

The adoption of Q-glass (quartz glass fabric) provides superior low-dielectric performance for 1.6 Tbps speeds but introduces extreme toughness. As micro-holes shrink to 0.2–0.15 mm, drills face immense stress. Without extreme rigidity and microstructural uniformity, manufacturers face high rates of hole deviation, rough walls, and tool breakage.

●AXISMATERIA: The Tungsten Carbide Advantage

To meet M9 challenges, AXISMATERIA tungsten carbide rods (Sumitomo, Japan) offer the necessary high rigidity and stability.

1.HIP Processing: Hot Isostatic Pressing eliminates internal micro-cracks and increases density.

2.Nano-Grain Tech: Grades like AF209, AF308, and AF308H (grain sizes 0.2–0.3 μm) provide the ultimate balance of hardness and fracture toughness.

3.Precision: These materials support micro-drills (0.1–0.8 mm) under high-speed spindle operations, ensuring consistent accuracy.

The M9 era redefines PCB competitiveness through material innovation. In this high-stakes landscape, AXISMATERIA rods transform drill bits from simple tools into core determinants of AI manufacturing success.

●M9 Substrates: High Performance, High Difficulty

M9-grade substrates must achieve the "three lows": Low Dk (dielectric constant), Low Df (loss), and Low CTE (thermal expansion). While essential for high-frequency signal integrity, these properties increase material hardness and density. This makes machining exceptionally difficult; while a standard PCB allows 10,000 holes per drill, M9 substrates can reduce tool life to just 200 holes.

●Q-glass: Pushing Drilling to the Limit

The adoption of Q-glass (quartz glass fabric) provides superior low-dielectric performance for 1.6 Tbps speeds but introduces extreme toughness. As micro-holes shrink to 0.2–0.15 mm, drills face immense stress. Without extreme rigidity and microstructural uniformity, manufacturers face high rates of hole deviation, rough walls, and tool breakage.

●AXISMATERIA: The Tungsten Carbide Advantage

To meet M9 challenges, AXISMATERIA tungsten carbide rods (Sumitomo, Japan) offer the necessary high rigidity and stability.

1.HIP Processing: Hot Isostatic Pressing eliminates internal micro-cracks and increases density.

2.Nano-Grain Tech: Grades like AF209, AF308, and AF308H (grain sizes 0.2–0.3 μm) provide the ultimate balance of hardness and fracture toughness.

3.Precision: These materials support micro-drills (0.1–0.8 mm) under high-speed spindle operations, ensuring consistent accuracy.

The M9 era redefines PCB competitiveness through material innovation. In this high-stakes landscape, AXISMATERIA rods transform drill bits from simple tools into core determinants of AI manufacturing success.

A Sun Phototnics

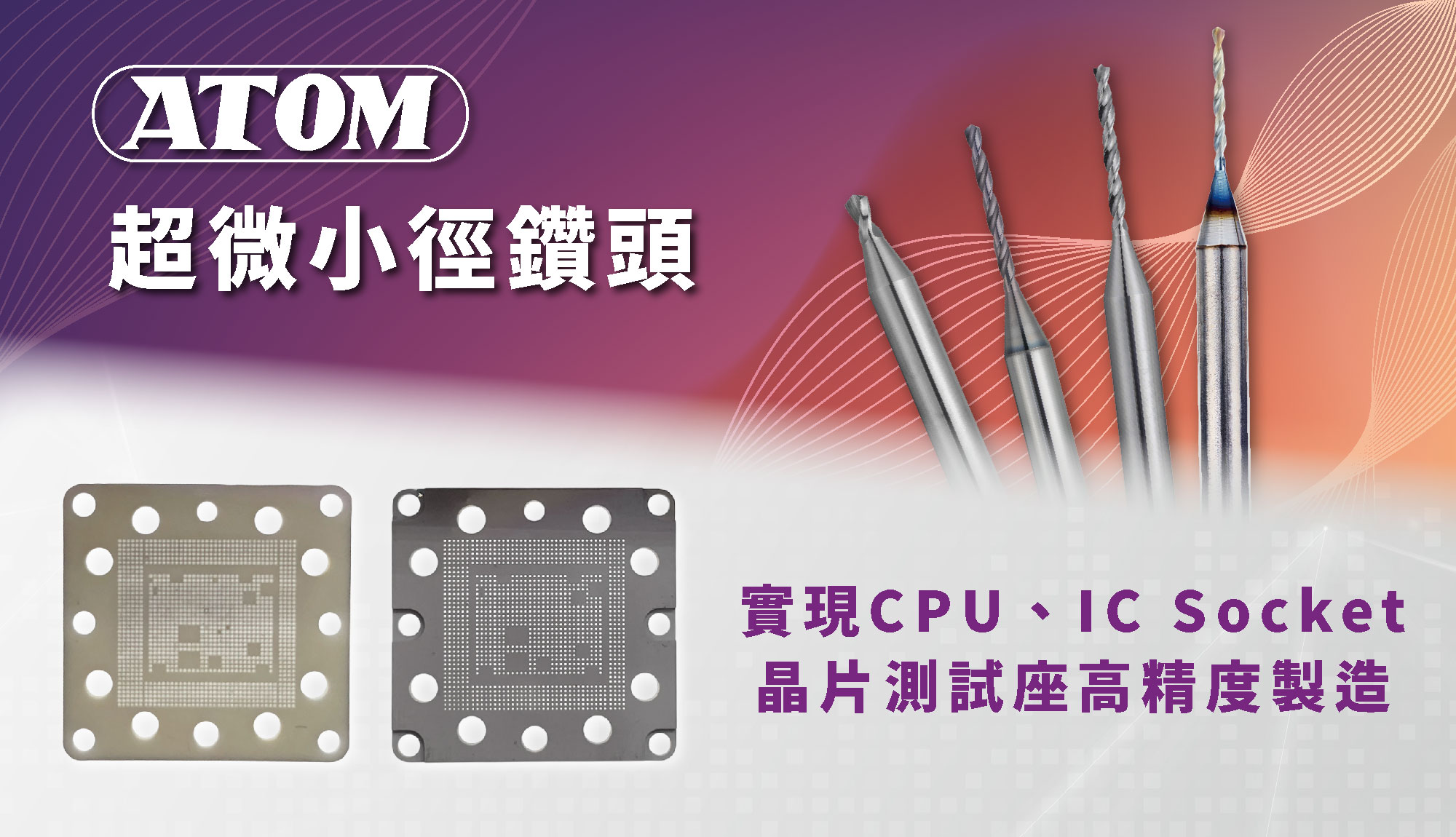

Brand Name:

ATOM、AXISMATERIA、ASP-LASER、YUKIWA、SUMITOMO、A.L.M.T

Booth Number :

E0301

Contact Information :

- asun-photonics.com/

- +886-02-26327601

- +886-02-26327604

- 1F., No. 417-1, Sec. 6, MinChuan Road, Neihu District, Taipei City 114, Taiwan