In semiconductor manufacturing, the Shower Head (gas distribution plate) is a critical component in plasma etchers and CVD systems, responsible for uniformly distributing process gases across the wafer surface. Although its structure appears simple, a single Shower Head can cost over USD 12,000 due to extremely stringent machining requirements.

The surface contains thousands of micro-holes, demanding exceptional hole diameter accuracy, consistency, and burr-free inner walls. Any deviation in hole size or surface quality may lead to non-uniform film thickness, directly affecting process stability and equipment yield.

Aluminum alloy is the most widely used metallic material for Shower Heads due to its excellent thermal conductivity and corrosion resistance. Non-metallic materials include CVD-SiC, monocrystalline silicon, quartz, and high-purity ceramics. Typical micro-hole diameters range from 0.2 to 6.0 mm, requiring extremely stable and precise drilling performance.

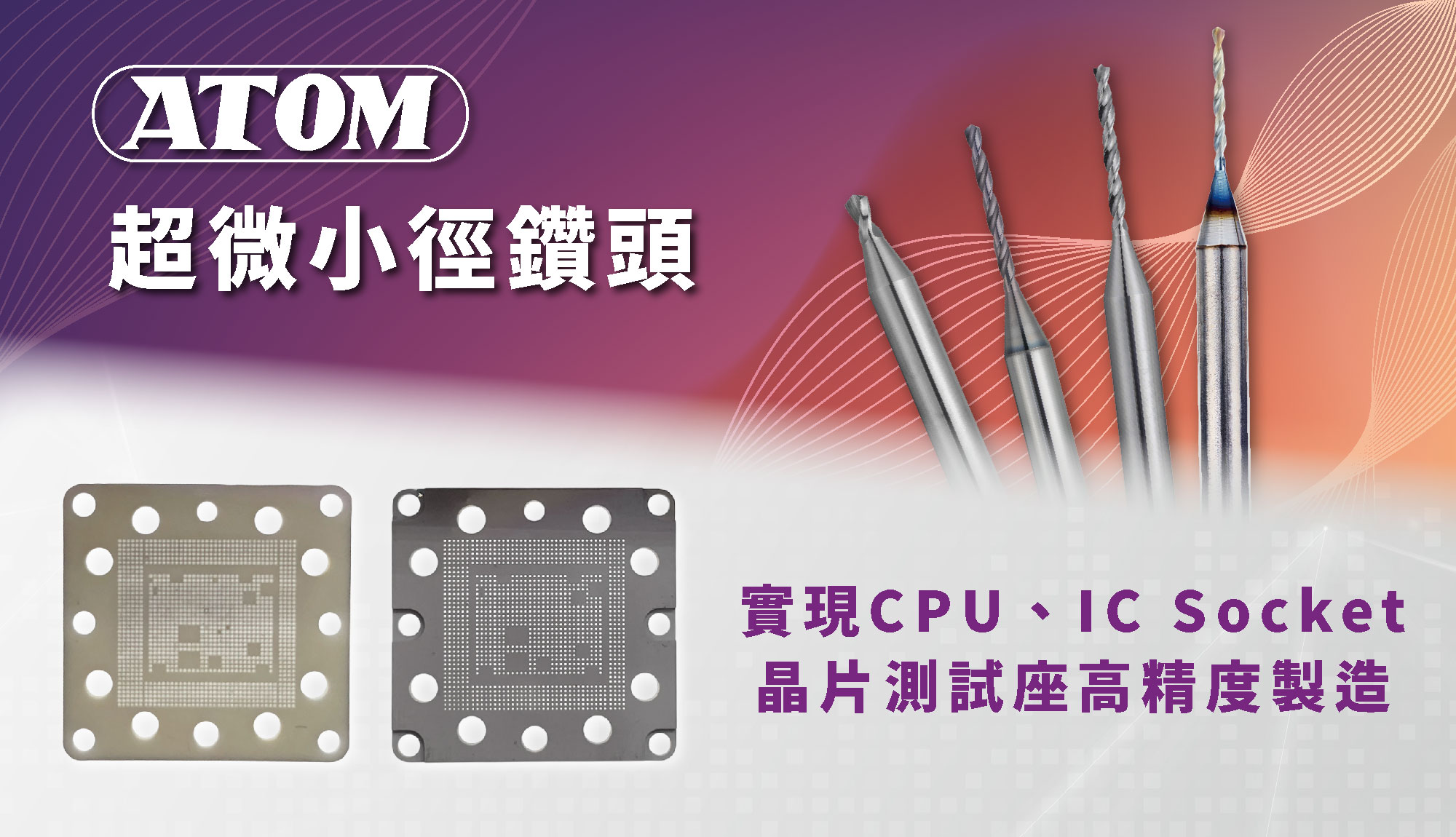

ATOM Japan – Micro-Drill Solutions for Shower Head Machining

1. NC Spotting Drill – Accurate Positioning from the Start

Diameter range: Ø0.02–Ø3.0 mm

Point angles: 90° / 120°

Materials: steel, PEEK, non-ferrous metals, resins

2. DLC-Coated Micro Drill – Longer Tool Life, Higher Efficiency

DLC Shine Coating, ultra-high hardness (sp³ up to 60 GPa)

Low friction, reduced chip adhesion, improved chip evacuation

Ideal for aluminum alloys and copper

ATOM also provides custom through-coolant micro drills based on hole diameter, depth, and workpiece material. In Shower Head applications, ATOM micro drills significantly improve chip evacuation, hole wall smoothness, and diameter consistency, even in high-volume production.

ASP is the official distributor of ATOM Japan in Taiwan, offering a complete micro-drill product lineup, including ADR, ADR-SV, NC, ASWR/ASWD, ADR-DLC, ADS, and SXG series.

【Contact Information】

Tel: +886-2-26327601

Fax: +886-2-26327604

Website: https://asun-photonics.com/

The surface contains thousands of micro-holes, demanding exceptional hole diameter accuracy, consistency, and burr-free inner walls. Any deviation in hole size or surface quality may lead to non-uniform film thickness, directly affecting process stability and equipment yield.

Aluminum alloy is the most widely used metallic material for Shower Heads due to its excellent thermal conductivity and corrosion resistance. Non-metallic materials include CVD-SiC, monocrystalline silicon, quartz, and high-purity ceramics. Typical micro-hole diameters range from 0.2 to 6.0 mm, requiring extremely stable and precise drilling performance.

ATOM Japan – Micro-Drill Solutions for Shower Head Machining

1. NC Spotting Drill – Accurate Positioning from the Start

Diameter range: Ø0.02–Ø3.0 mm

Point angles: 90° / 120°

Materials: steel, PEEK, non-ferrous metals, resins

2. DLC-Coated Micro Drill – Longer Tool Life, Higher Efficiency

DLC Shine Coating, ultra-high hardness (sp³ up to 60 GPa)

Low friction, reduced chip adhesion, improved chip evacuation

Ideal for aluminum alloys and copper

ATOM also provides custom through-coolant micro drills based on hole diameter, depth, and workpiece material. In Shower Head applications, ATOM micro drills significantly improve chip evacuation, hole wall smoothness, and diameter consistency, even in high-volume production.

ASP is the official distributor of ATOM Japan in Taiwan, offering a complete micro-drill product lineup, including ADR, ADR-SV, NC, ASWR/ASWD, ADR-DLC, ADS, and SXG series.

【Contact Information】

Tel: +886-2-26327601

Fax: +886-2-26327604

Website: https://asun-photonics.com/

A Sun Phototnics

Brand Name:

ATOM、AXISMATERIA、ASP-LASER、YUKIWA、SUMITOMO、A.L.M.T

Booth Number :

E0301

Contact Information :

- asun-photonics.com/

- +886-02-26327601

- +886-02-26327604

- 1F., No. 417-1, Sec. 6, MinChuan Road, Neihu District, Taipei City 114, Taiwan