AF413X: A Breakthrough Cemented Carbide Blanks for Machining Difficult-to-Cut Material

In the machining of high-strength, heat-resistant, and high-hardness materials, tool wear and material adhesion have long been major challenges for engineers. AF413X uniquely combines excellent anti-adhesion performance with outstanding chipping resistance, effectively addressing the severe tool wear and edge chipping commonly encountered when machining titanium alloys and nickel-based superalloys using conventional cutting tool materials.

Two Core Technologies Driving Superior Performance

The exceptional performance of AF413X is achieved through an in-depth analysis of cutting tool failure mechanisms and the integration of two key technologies:

1. Fine and Homogeneous Cobalt (Co) Dispersion

By uniformly dispersing the cobalt binder phase at a microstructural level, AF413X significantly suppresses titanium adhesion during machining. This results in a more stable cutting process and improved surface quality.

2. Enhanced WC Grain Bonding Technology

The bonding strength between tungsten carbide (WC) grains is greatly increased, effectively preventing WC grain pull-out and edge chipping. This delivers excellent chipping resistance and significantly extends tool life under demanding cutting conditions.

Typical Difficult-to-Cut Materials

Titanium Alloy Ti-6Al-4V

Nickel-Based Superalloy Inconel 718

Stainless Steel SUS630 (17-4PH)

Tool Steel SKD61 (H13 equivalent)

AXISMATERIA cemented carbide milling tool material AF413X maintains edge integrity even under high-temperature and high-hardness machining conditions, providing stable cutting performance, extended tool life, and improved machining efficiency.

【Contact Information】

Tel: +886-2-26327601

Fax: +886-2-26327604

Line@ : https://line.me/R/ti/p/%40332yetoa

Website: https://asun-photonics.com/

In the machining of high-strength, heat-resistant, and high-hardness materials, tool wear and material adhesion have long been major challenges for engineers. AF413X uniquely combines excellent anti-adhesion performance with outstanding chipping resistance, effectively addressing the severe tool wear and edge chipping commonly encountered when machining titanium alloys and nickel-based superalloys using conventional cutting tool materials.

Two Core Technologies Driving Superior Performance

The exceptional performance of AF413X is achieved through an in-depth analysis of cutting tool failure mechanisms and the integration of two key technologies:

1. Fine and Homogeneous Cobalt (Co) Dispersion

By uniformly dispersing the cobalt binder phase at a microstructural level, AF413X significantly suppresses titanium adhesion during machining. This results in a more stable cutting process and improved surface quality.

2. Enhanced WC Grain Bonding Technology

The bonding strength between tungsten carbide (WC) grains is greatly increased, effectively preventing WC grain pull-out and edge chipping. This delivers excellent chipping resistance and significantly extends tool life under demanding cutting conditions.

Typical Difficult-to-Cut Materials

Titanium Alloy Ti-6Al-4V

Nickel-Based Superalloy Inconel 718

Stainless Steel SUS630 (17-4PH)

Tool Steel SKD61 (H13 equivalent)

AXISMATERIA cemented carbide milling tool material AF413X maintains edge integrity even under high-temperature and high-hardness machining conditions, providing stable cutting performance, extended tool life, and improved machining efficiency.

【Contact Information】

Tel: +886-2-26327601

Fax: +886-2-26327604

Line@ : https://line.me/R/ti/p/%40332yetoa

Website: https://asun-photonics.com/

A Sun Phototnics

Brand Name:

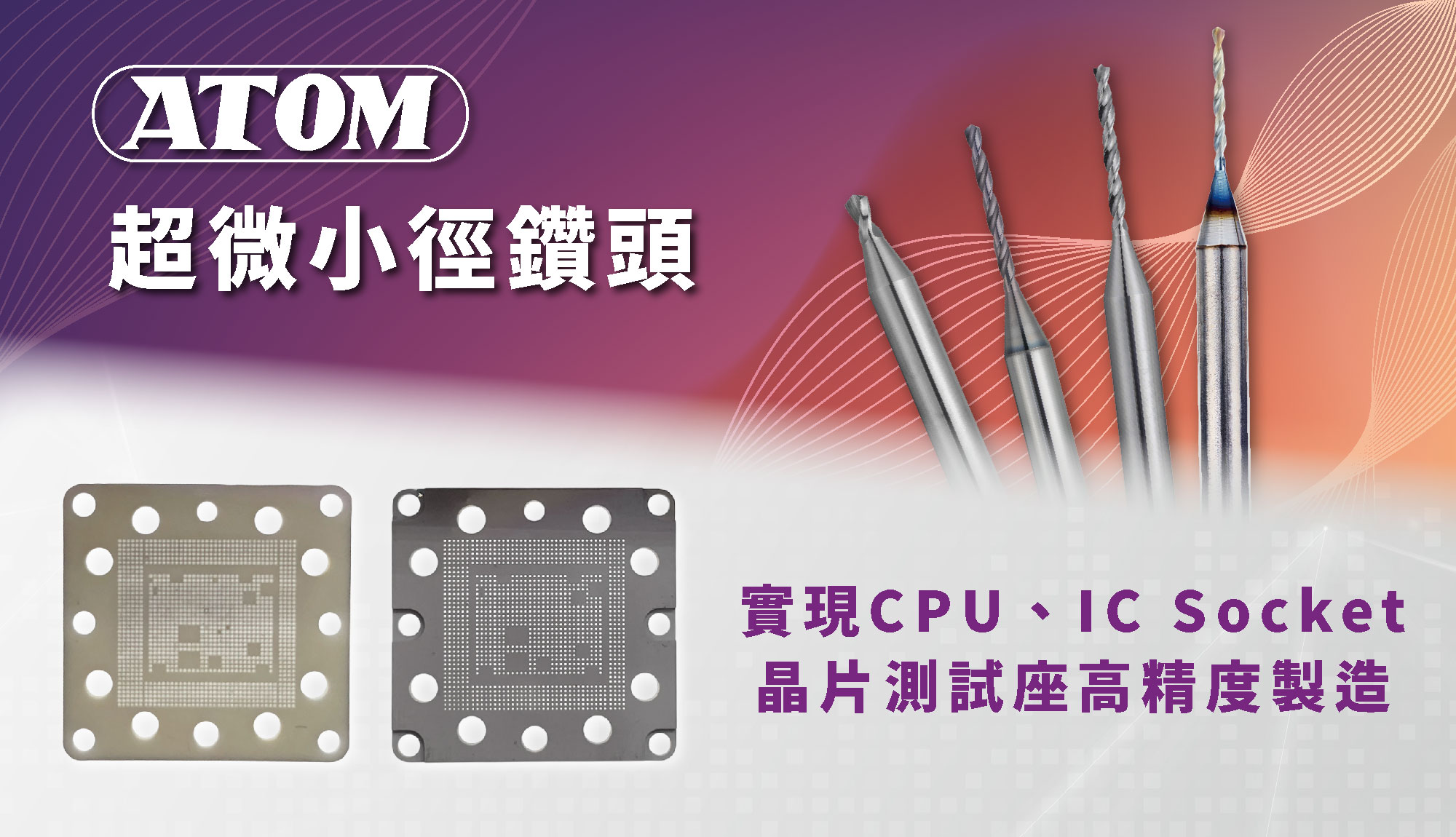

ATOM、AXISMATERIA、ASP-LASER、YUKIWA、SUMITOMO、A.L.M.T

Booth Number :

E0301

Contact Information :

- asun-photonics.com/

- +886-02-26327601

- +886-02-26327604

- 1F., No. 417-1, Sec. 6, MinChuan Road, Neihu District, Taipei City 114, Taiwan