SIDE MILLING CUTTER SERIES

Product Description :

Precision Groove Cutting × Rigidity Enhancement × Stable Deep Cutting — The Right Way to Use a Side Milling Cutter

Professional machining isn’t about luck or experience — it’s about precision in every cut.

Chain Headway’s Side Milling Cutter Series helps you achieve precise results from every side of your workpiece!

🛠 Why is the side milling cutter one of the most valued tools for technicians?

In high-rigidity, high-precision machining environments, the side milling cutter isn’t just a tool for making keyways and slots — it’s a critical factor in overall process stability.

Whether machining drainage grooves on aluminum alloy wheels, O-ring grooves on mold guide posts, or keyways on gear exteriors, any deviation in tool balance, cutting force, or chip evacuation can lead to edge chipping, poor machining quality, or even workpiece scrap.

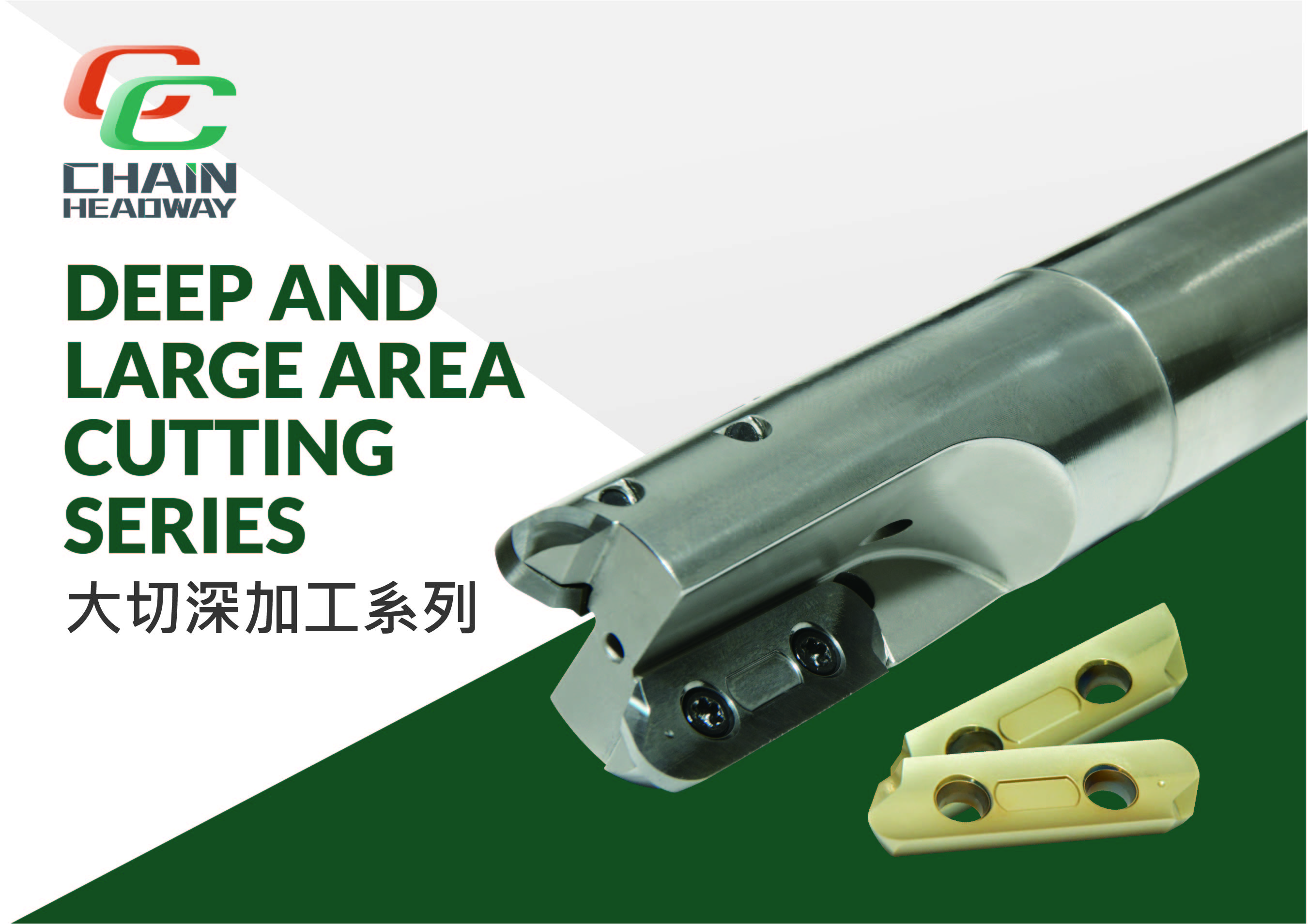

🧰 Tool Body Design Advantages

• Finish-machined after pre-hardening to reduce runout caused by heat-treatment deformation

• Pre-centered insert seat for higher mounting precision and symmetry

• High contact ratio at the slot base to suppress micro-vibration under cutting load

• Multiple bore sizes (B22, B27, B32, B40, B50) for flexible compatibility with spindles or extension holders

Professional machining isn’t about luck or experience — it’s about precision in every cut.

Chain Headway’s Side Milling Cutter Series helps you achieve precise results from every side of your workpiece!

🛠 Why is the side milling cutter one of the most valued tools for technicians?

In high-rigidity, high-precision machining environments, the side milling cutter isn’t just a tool for making keyways and slots — it’s a critical factor in overall process stability.

Whether machining drainage grooves on aluminum alloy wheels, O-ring grooves on mold guide posts, or keyways on gear exteriors, any deviation in tool balance, cutting force, or chip evacuation can lead to edge chipping, poor machining quality, or even workpiece scrap.

🧰 Tool Body Design Advantages

• Finish-machined after pre-hardening to reduce runout caused by heat-treatment deformation

• Pre-centered insert seat for higher mounting precision and symmetry

• High contact ratio at the slot base to suppress micro-vibration under cutting load

• Multiple bore sizes (B22, B27, B32, B40, B50) for flexible compatibility with spindles or extension holders

Catalog :

CHAIN HEADWAY CO., LTD

Brand Name:

CC CHAIN HEADWAY

Booth Number :

H0301

Contact Information :

- www.chain-headway.com

- +886-4-26265252

- +886-4-26267941

- No.232, Wuquan Rd., Qingshui Dist., Taichung City 436037, Taiwan