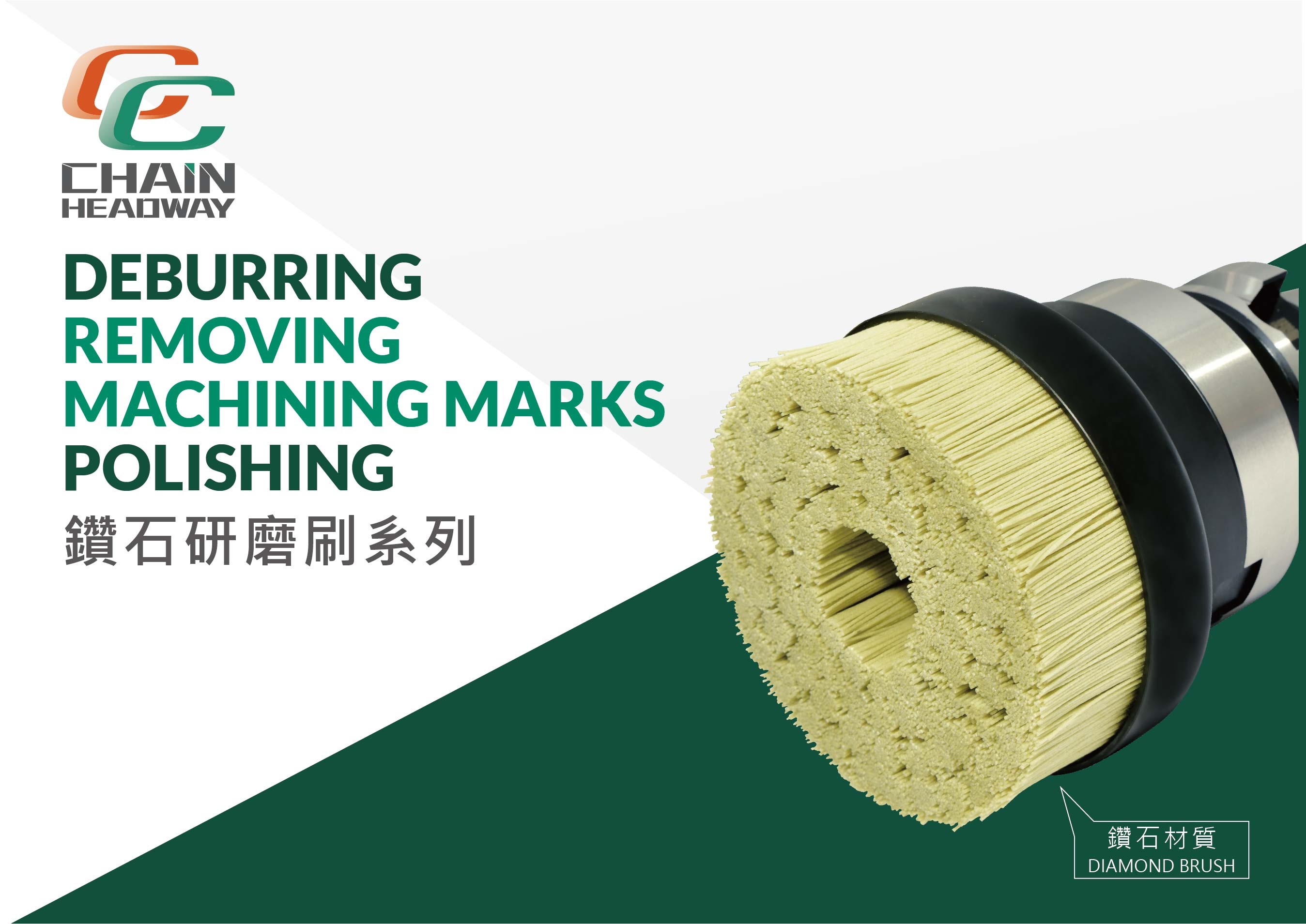

DEBURRING REMOVING MACHINING MARKS POLISHING

Product Description :

Surface Finishing Technologies in Cutting Processes: The Application of Diamond Grinding Brushes

In modern manufacturing, cutting machining is a key method for producing precision components.

However, after cutting, the workpiece surface often exhibits defects such as tool marks and burrs, requiring further surface finishing to meet quality standards.

This article introduces an efficient surface finishing technology — the diamond grinding brush — and explores its applications in cutting processes.

Features of Diamond Grinding Brushes

Diamond grinding brushes use diamond as the abrasive material and have the following notable characteristics:

• High hardness and wear resistance:

Diamond is the hardest known material, enabling diamond grinding brushes to process workpieces of various hardness levels while maintaining long-lasting cutting performance.

• Excellent elasticity and toughness:

The bristles of the grinding brush possess good flexibility and resilience, allowing them to adapt to complex workpiece surfaces and achieve uniform grinding results.

• Controllable grinding effect:

By selecting diamond brushes with different grit sizes, users can perform a full range of surface treatments — from rough to fine finishing — depending on the required surface quality.

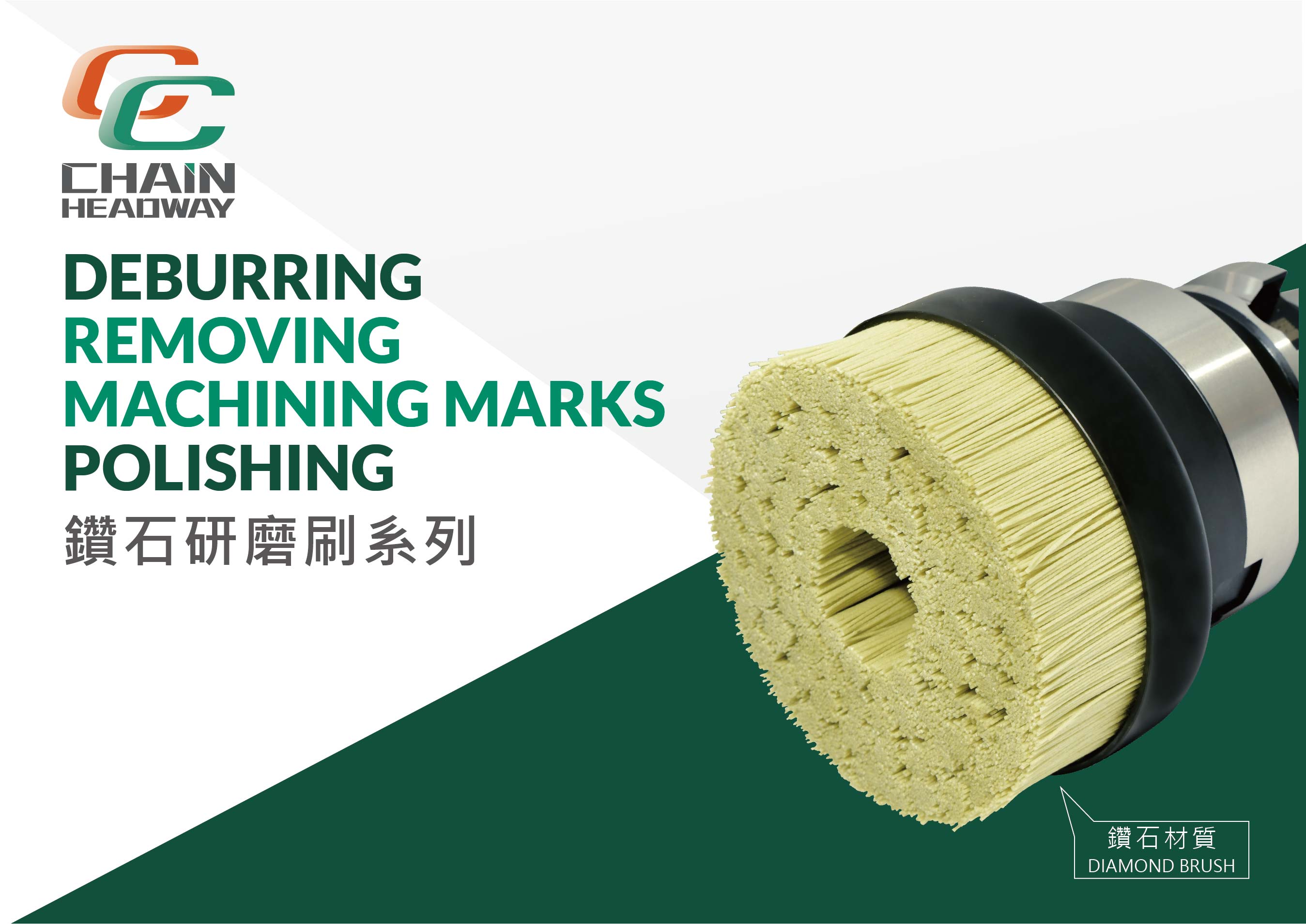

The “Eight Diamond Kings” of Diamond Grinding Brushes and Their Functions

The diamond grinding brush series includes multiple shapes and sizes, collectively known as the “Eight Diamond Kings.”

Each type is designed for specific functions and applications:

• Shell-shaped:

Primarily used for deburring and polishing. Features strong, resilient bristles with excellent fatigue resistance.

• Straight Shank:

Used for deburring and polishing applications.

• T-shaped:

Also used for deburring and polishing purposes.

• Ball-shaped:

Although not explicitly described, based on its shape, it is likely suitable for grinding curved or complex surfaces.

• Rod-shaped:

Likely used for grinding narrow areas or internal holes due to its elongated design.

• Plate-shaped:

Produced upon order; typically used for large surface grinding or specialized surface finishing requirements.

• Adjustable:

With an adjustable size design, it may be applied in situations requiring flexible control of the grinding area.

• Disc-shaped:

Commonly used for flat or cylindrical surface grinding applications.

In modern manufacturing, cutting machining is a key method for producing precision components.

However, after cutting, the workpiece surface often exhibits defects such as tool marks and burrs, requiring further surface finishing to meet quality standards.

This article introduces an efficient surface finishing technology — the diamond grinding brush — and explores its applications in cutting processes.

Features of Diamond Grinding Brushes

Diamond grinding brushes use diamond as the abrasive material and have the following notable characteristics:

• High hardness and wear resistance:

Diamond is the hardest known material, enabling diamond grinding brushes to process workpieces of various hardness levels while maintaining long-lasting cutting performance.

• Excellent elasticity and toughness:

The bristles of the grinding brush possess good flexibility and resilience, allowing them to adapt to complex workpiece surfaces and achieve uniform grinding results.

• Controllable grinding effect:

By selecting diamond brushes with different grit sizes, users can perform a full range of surface treatments — from rough to fine finishing — depending on the required surface quality.

The “Eight Diamond Kings” of Diamond Grinding Brushes and Their Functions

The diamond grinding brush series includes multiple shapes and sizes, collectively known as the “Eight Diamond Kings.”

Each type is designed for specific functions and applications:

• Shell-shaped:

Primarily used for deburring and polishing. Features strong, resilient bristles with excellent fatigue resistance.

• Straight Shank:

Used for deburring and polishing applications.

• T-shaped:

Also used for deburring and polishing purposes.

• Ball-shaped:

Although not explicitly described, based on its shape, it is likely suitable for grinding curved or complex surfaces.

• Rod-shaped:

Likely used for grinding narrow areas or internal holes due to its elongated design.

• Plate-shaped:

Produced upon order; typically used for large surface grinding or specialized surface finishing requirements.

• Adjustable:

With an adjustable size design, it may be applied in situations requiring flexible control of the grinding area.

• Disc-shaped:

Commonly used for flat or cylindrical surface grinding applications.

CHAIN HEADWAY CO., LTD

Brand Name:

CC CHAIN HEADWAY

Booth Number :

H0301

Contact Information :

- www.chain-headway.com

- +886-4-26265252

- +886-4-26267941

- No.232, Wuquan Rd., Qingshui Dist., Taichung City 436037, Taiwan