Theme

Digital Transformation

Green Transformation

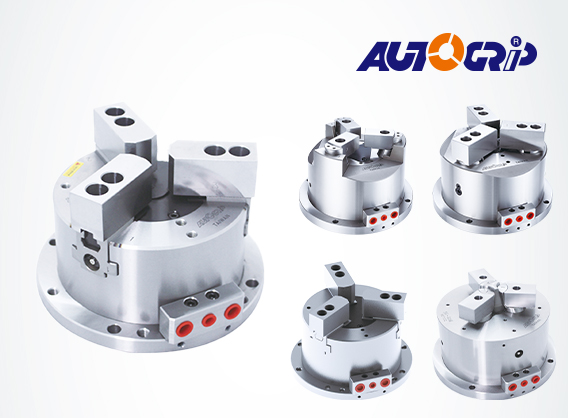

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

Brand new upgrade! Introducing the Grip Force Sensor (GFS-100) with advanced gripping technology. Bluetooth 5.0 ensures exceptional wireless connectivity, making your operations smoother. Convenient Type-C charging interface for easy charging, providing continuous power for your work. The high-performance lithium battery offers extended battery life, eliminating concerns about power shortage during work and allowing you to focus on your tasks. GFS-100 supports both Android and iOS systems, ensuring seamless compatibility for a user-friendly experience. With the flexibility to configure as a 2-claw or 3-claw operation based on your actual needs, it provides greater operational versatility. Upgrade your work experience with GFS-100, showcasing the convenience and efficiency of cutting-edge technology.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

YA LIANG INDUSTRIAL CO., LTD.

Product Description :

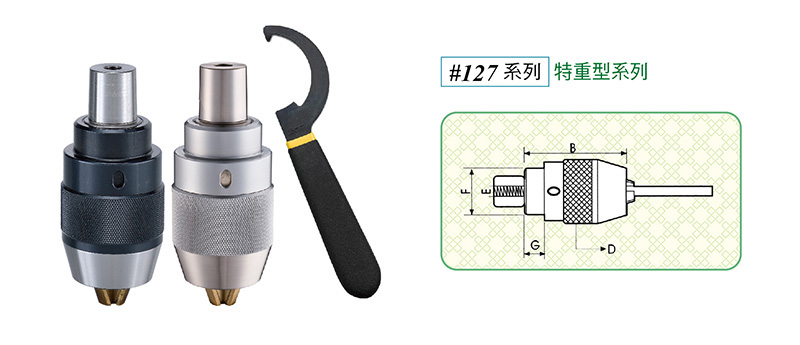

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.