Theme

Digital Transformation

Green Transformation

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

AZ series has a "Direct Force" design on the concept of X/Y axes linear guideway blocks keep staying in a straight line. The working table is supported by casting bases. AZ series is suitable for precision mold cutting within small / medium strokes.

A Sun Phototnics

Product Description :

AXISMATERIA 自創立以來,即致力於生產PCB印刷電路板鑽孔用的小徑鑽頭超硬素材,以超微粒碳化鎢為原料,具備高硬度與高韌性,並在全球市場中擁有壓倒性的市佔率。如今近九成產品銷售對象已拓展至全球各大刀具、模具與微細加工業者,涵蓋切削工具、耐磨工具等多種用途。

AXISMATERIA 採用與住友集團相同規格的高階粉末與燒結技術,確保材料品質的一致性與穩定性,遠勝一般供應商。

多樣化產品線涵蓋:

• 超硬合金圓棒(Round Rods)

• 成型棒材(Formed Round Rods)

• PCB 專用圓棒(Blanks for PCB drill)

• 航太醫療難削材加工用銑刀素材AF413X

• 數控刀具素材

• 圓鋸素材

• 各種用途毛坯與客製品

在高精度刀具製造與模具加工領域,選擇來自穩定供應鏈的高品質材料是確保效率與成本競爭力的關鍵。

AXISMATERIA 提供的不僅是超硬合金棒材,更是由住友電工供應鏈背書的品質保證——從原料採礦、粉末提煉,到成品製造皆可追溯與管控,是業界信賴的全球合作夥伴。

-------------------------------------------------

在台灣地區,AXISMATERIA 授權由 岳崴科技股份有限公司 擔任正式一級代理,負責產品銷售、技術諮詢與在地售後支援。

岳崴科技自 2002 年起深耕精密刀具與鎢鋼材料應用領域,服務涵蓋工具機、模具、航太、電子與半導體產業,擁有超過 20 年實務經驗與技術選材能力。

透過對各類加工條件、粉末合金規格、熱處理與刀具壽命管理的深入理解,岳崴科技可協助客戶量身選配適用材料並提供一站式應用解決方案。

【聯絡資訊】

電話: +886-2-26327601

傳真: +886-2-26327604

Line@官方客服:https://line.me/R/ti/p/%40332yetoa

網站:https://asun-photonics.com/

GP MACHINERY CO., LTD.

Product Description :

The Hiteco birotary heads series Tilt HX PLUS (90 °) are ideal for light alloys, composite materials and plastics working. Discover the liquid cooled electrospindles available with the various configurations.

Advantages:

1. Designed for machining composite materials, plastic and light alloys

2. Optimisation of the machining times thanks to the high positioning speeds

3. Excellent stiffness despite the light weight

JAR HON MACHINERY CO., LTD.

Product Description :

1.Attached with multi head which can drill many parts at the same time in order to enhance efficiency.

2.Design a complete unit of multi head, guiding hole plate and jig in order to have high accuracy.

3.Suitable for reaming, drilling and chamfering.

4.Optional functions: "Auto. discharging chips" and "Auto. breaking chips".

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

The oil-water separator can separate the slide oil and cutting oil from the water in the water tank of the machine tool, thereby realizing the centralized discharge of waste oil while maintaining clean oil and water for circulating filtration. Features: It can be used without horizontal calibration and has a built-in double-layer impurity interception device to ensure efficiency and safety during operation. It is easy to install and use, and can easily extend the service life of the cutting fluid. It adopts pneumatic drive, which is safer and more reliable. The product has zero consumables and no additional burden.

CHAIN HEADWAY CO., LTD

Product Description :

The Art of Cutting — Tailored for You

PCD, CBN & Carbide Precision Inserts × Your Best Choice for Custom Machining Solutions

🎯 “It’s not about choosing our products — it’s about choosing our solutions.”

In today’s era of ultra-fast, high-precision, and high-efficiency machining, standardized inserts can no longer meet the challenges of diverse processes and materials.

Chain Headway offers more than just inserts — we deliver complete cutting solutions customized to your materials, equipment, and productivity goals.

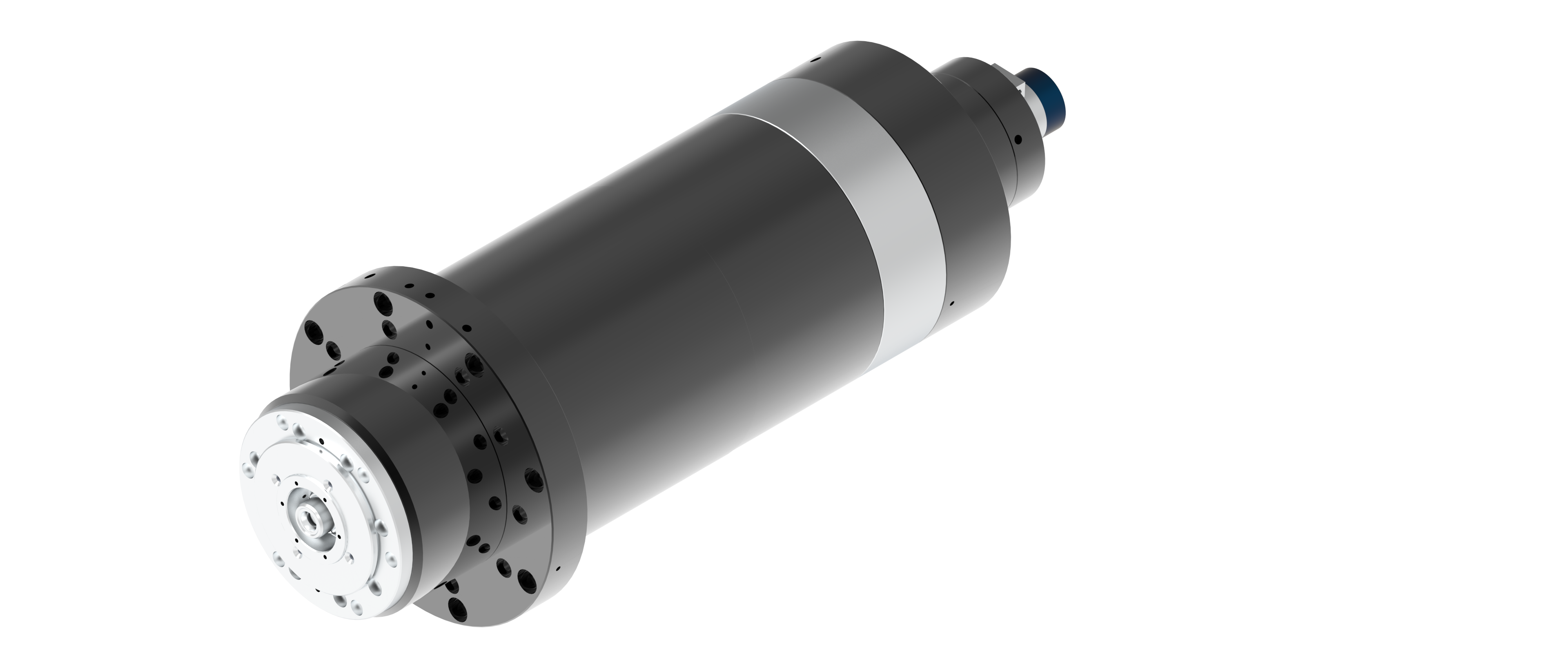

GP MACHINERY CO., LTD.

Product Description :

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Compact hydraulic power packs are a type of hydraulic power pack. They arecharacterised by a highly compact design, since the motor shaft of the electric drive also acts as the pump shaft. Compact hydraulic power packs are designed to supply hydraulic circuits with hydraulic fluid.

The compact hydraulic power pack type INKA consists of the tank, the integrated motor and the radial piston pump or gear pump directly attached to the motor

shaft. The directly mounted electronic communication box with integrated realtime operating system allows the operating state to be recorded and visualised. The

measured values of the integrated multi-sensor (including the motor speed) can be passed on to the higher-level machine controls via standardised interfaces and processed there.

The consistently modular design of the type INKA means that different usage volumes and delivery flows can be realised quickly and easily from the modular

system. Compatible, ready-for-connection, complete solutions can be assembled easily using a wide range of connection blocks and the valve banks that can be combined with them.

Features and benefits

■ Prepared for condition monitoring with integrated sensors and communication box

■ Optimum efficiency through under-oil motor cooling, direct power transmission,and sophisticated heat dissipation

■ Suitable for nominal operating modes S2 (short period operation) and S3 (periodic intermittent operation)

■ Resource-saving due to small oil filling volume

Intended applications

■ Machine tools and material testing

■ Hydraulic tools

■ Handling systems

■ Presses and processing machines