Theme

Digital Transformation

Green Transformation

ADLEE POWERTRONIC CO., LTD.

Product Description :

Apply every transmission machines.

The general AC induction electric motor is designed with IEC standard. These motors fit a variety of industrial applications and it is convenient for new and used applications. Electric motor power is available from 0.25 to 20HP. The frame size is from 63 to 160.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURE:

Compliant with IEC 61672-1 class 1 standard

Dynamic range of 90dB

AC and DC outputs

Data transfer using USB

microSD card

Real-time 1/1-Octave and 1/3-Octave analysis

Measurement can be started by internal or external trigger

Comparator output to trigger external devices

Super high – contrast backlight TFT – LCD color display

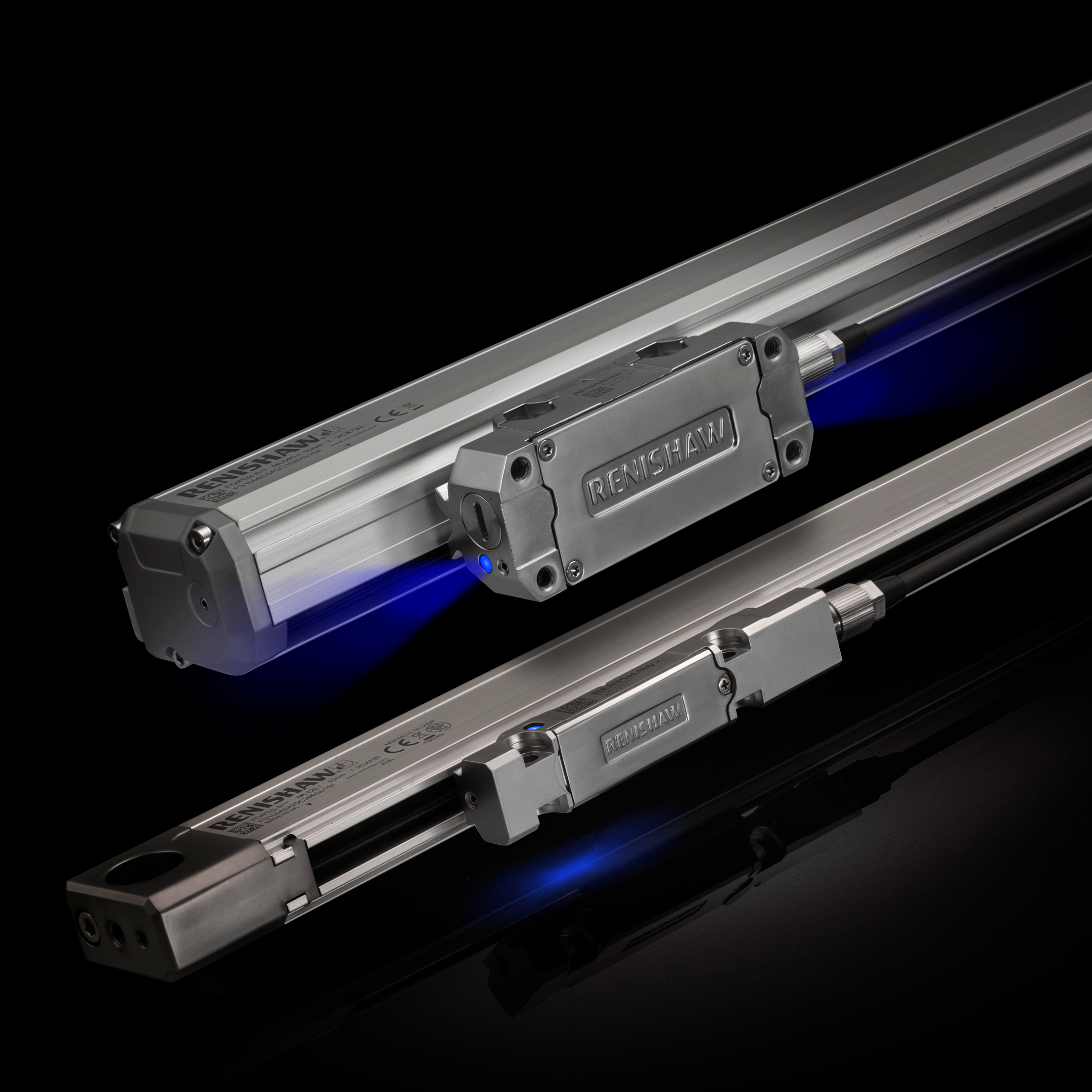

RENISHAW (TAIWAN) INC.

Product Description :

Renishaw 提Renishaw 提供各式各樣的封閉式光學尺,也稱為密封式光學尺。歡迎瞭解我們的絕對式量測技術搭配強大的密封及非接觸設計,如何在工具機等惡劣環境中協助提升精密製造。

在最惡劣的環境中運作的位置光學尺

FORTiS 線性光學尺採用 Renishaw 深獲業界肯定的 RESOLUTE™ 絕對式光學尺技術,以堅固的封閉式設計在最惡劣環境中提供高效能量測,展現超越傳統系統的重大效益:

• 非接觸式設計 - 無機械磨損並延長使用壽命。

• 降低遲滯 - 更順暢的回饋和更好的動態效能。

• 突破性的讀頭設計 - 調諧質量阻尼器協助實現領先同類產品的抗振效果(高達 30 g)。

• 符合 IP64 標準的卓越密封等級 - 優異的密封技術可加強保護,避免液體及固體碎屑污染。

• 採用專利方法裝設的 LED - 完整 LED 訊號強度指示器,可進行簡單快速的安裝和設定。

• 減少洩漏空氣可降低淨化空氣用量。

我們也提供兩種不同的鋁擠型尺寸以配合空間需求:FORTiS-S™ 標準寬度 (37 mm) 及 FORTiS-N™ 精細型 (18 mm)。FORTiS 線性光學尺也設計為可直接取代傳統的玻璃線性光學尺,提供完全相容的安裝、外型及功能,可於現有機台配置快速輕鬆地進行安裝。兩種尺寸均提供功能安全 (FS) 版本。

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

TORNG INDUSTRIAL CO., LTD.

Product Description :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

The brand-new product CNC Vertical Complex Grinding Machine SVG-E800 (SVG series), suitable for composite grinding of inner and outer diameters and end faces of various big cylindrical workpieces. Its mechanical structure adopts a double column type design, featuring high rigidity, high precision, high stability, and high efficiency. It is encased in aesthetically pleasing fully enclosed safety covers, and can be equipped with controllers from Fanuc, Mitsubishi, or the latest generation. With its conversational interface, operation is intuitive and easy. The grinding wheel spindle system is HSK-A100, 10000rpm, 18.5/15kw, capable of automatically changing wheel holders, with an ATC device capacity of 6 tools, and a spindle angle positioning system at 0 degrees/22.5 degrees, enabling various grinding processes with just one clamping. The workpiece spindle adopts a hydrostatic system turntable with a diameter of 800mm, maintaining axial movement accuracy <1μm. Models with turntable diameters of 600mm and 1200mm are also available. For further technical specifications, please contact the Sales Department of SIGMA CNC.

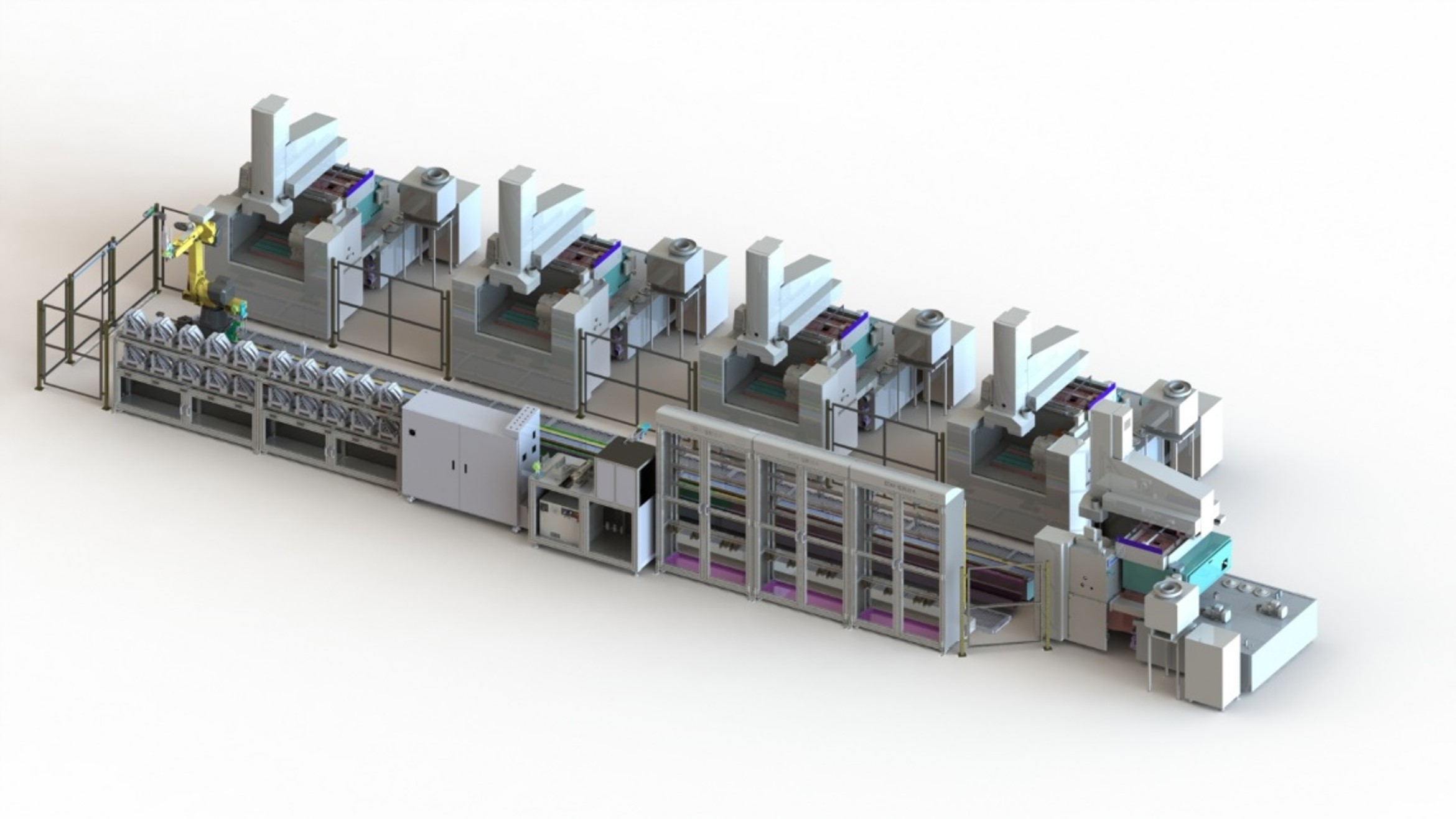

OSCAR E.D.M. COMPANY LTD.

Product Description :

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year

YI CHANG MACHINERY CO., LTD.

Product Description :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!