Theme

Digital Transformation

Green Transformation

NINE-9 CUTTING TOOLS CO., LTD.

Product Description :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

7-LEADERS CORP.

Product Description :

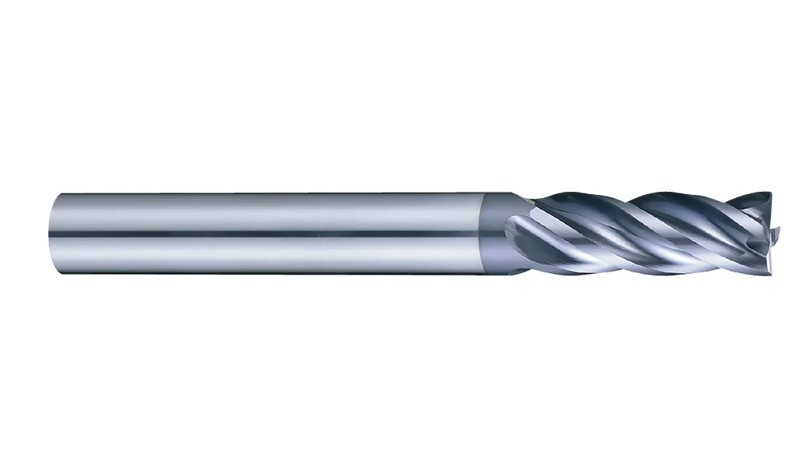

Multipurpose End Mills- 4 Flutes

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Obviously improve tool life with Nano multilayer coating AlTiCrN.

Suitable for different kinds of materials cutting.

HYDEX MACHINERY INDUSTRIAL CO., LTD.

Product Description :

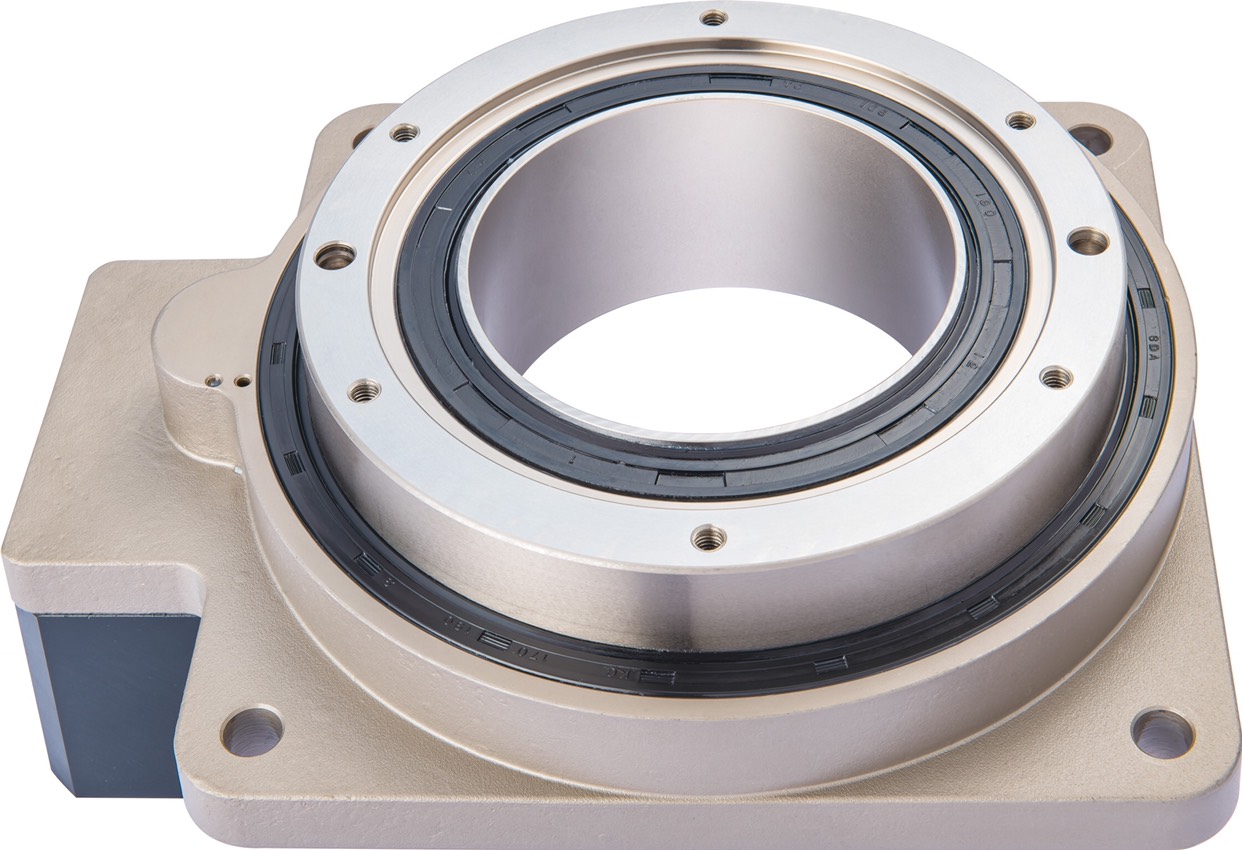

The hollow rotating platform is a brand-new kind of rotating load device. Incorporating high transmission eciency, high precision, high rigidity, and highcost performance, it combines the advantages of the servo motor, cam divider andDDmotor, obtaining a balance between these three products.

Compared with other similar transmission and location products, it not only can meet the point of ‘direct load to carrying capacity’, which is not achieved by the servo motor, but can also make up for the deciency that the divider cannot achieve at any angle location, namely, ‘achieving the location of any angle, and also compares favorably with the DD motor in precision. Furthermore, the cost is considerably less than that of the DD motor. Used together with the servo motor, it can completely meet your requirements from periphery positioning control.

SHAN HUA PLASTIC INDUSTRIAL CO., LTD.

Product Description :

PU pneumatic tubing is commonly used in machine tools and industrial automation equipment for pneumatic piping and compressed air systems.

The tubing offers high flexibility and good abrasion resistance, making it suitable for routing in applications requiring bending or movement of machine components.

Both PU Ester and PU Ether materials are available, along with multiple sizes and color options for easier installation and air line identification.

• PU Ester: Suitable for general industrial pneumatic systems

• PU Ether: Suitable for high-humidity environments or applications requiring hydrolysis resistance

IGUS TAIWAN COMPANY LTD.

Product Description :

免潤滑的滑動軸承技術——立即更換並將成本降低高達40%<br />

<br />

●免保養 iglidur® 滑動軸承<br />

透過免潤滑和減少保養工作來降低成本並增加使用壽命,所有產品均現貨供應——這是所有 iglidur® 工程塑膠軸承的核心理念和目標。 <br />

igus® 自潤式軸承系列包括套筒軸承、法蘭軸承、華司, 推力墊圈、活塞環、卡箍滑動軸承和眾多其他設計。 iglidur® 自潤式軸承總能給您解決方案——不論是目錄系列,還是訂製的滑動軸承特別解決方案,您都能找到適合自己的產品。 1件起訂。 <br />

iglidur® 自潤式軸承適合自動批量生產、特別機器製造、水下應用、食品或煙草業、極限溫度和耐化學品以及簡易金屬板安裝等應用。 <br />

<br />

●自潤軸承iglidur® PRT -工程塑膠回轉環軸承<br />

工程塑膠回轉環軸承<br />

自潤軸承iglidur® PRT是一款轉盤軸承,具有igus®工程塑膠軸承經驗證的優點。 由自潤軸承iglidur® 製成的滑動片是完全的免維護和免潤滑 轉盤軸承座零件是用鋁製成的,自潤軸承iglidur® J搭配的滑動元件表面經硬質陽極化處理。所有夾緊螺絲均為不銹鋼材質。 <br />

<br />

●xiros®工程塑膠滾珠軸承<br />

xiros® 塑膠滾珠軸承實現了滾珠軸承市場的革命性發展。 當傳統的金屬滾珠軸承不再滿足使用要求時,通過使用xirodur高性能工程塑膠,許多應用可以成功實現免保養和乾式運行。<br />

<br />

更多資訊: https://www.igus.com.tw/

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

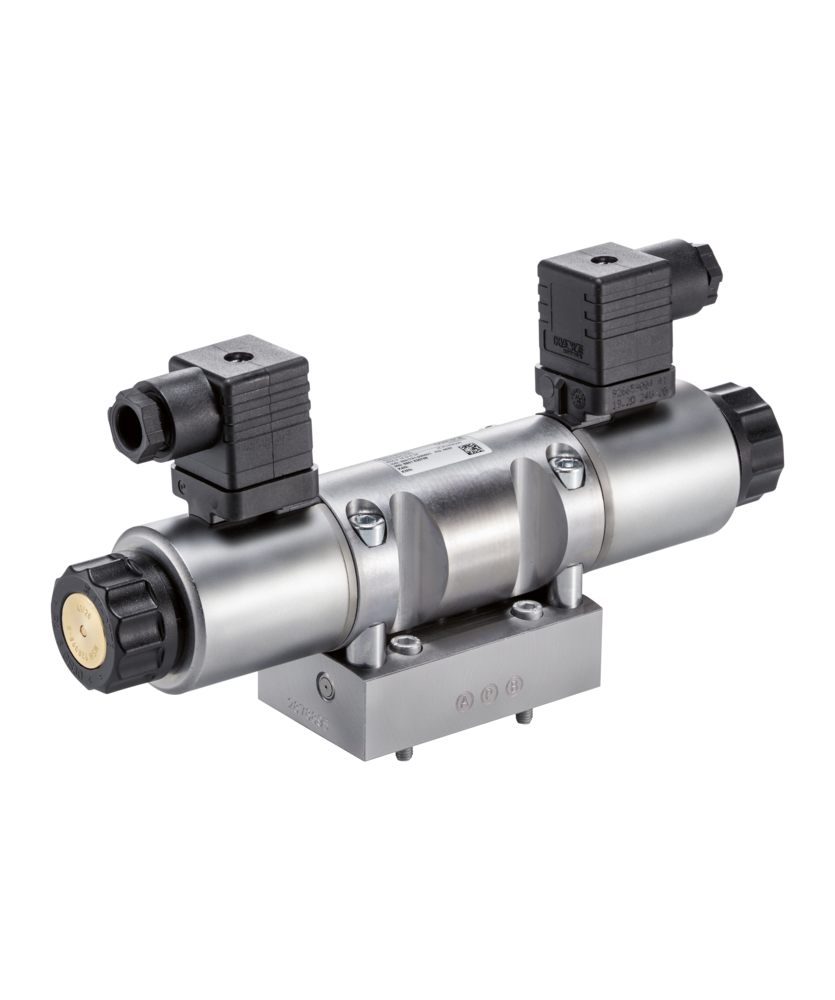

Directional seated valves are a type of directional valve. As cone valves they are tightly sealed, with zero leakage in the closed state.

The directional seated valve type ROLV is available as a 3/2, 4/2 or 4/3-way directional seated valve with different plug types. The patented assembly consists of two parts: a round basic valve with the valve inserts, and an adapter plate which can be designed for manifold mounting with nominal size NG 6 as the

standard connection pattern, or for direct pipe connection.

Additional elements such as a check valve, a restrictor (on the consumer side) and/ or restrictor check valves can be integrated, depending on the functional requirement and adapter plate. The type ROLV can be combined in the valve bank type BA with other types of valves.

Features and benefits

■ Dirt-resistant design with high switching reliability

■ Interchangeable solenoid for greater flexibility and easy servicing

Intended applications

■ Machine tools (cutting and non-cutting)

■ Clamping tools, punching tools, fixtures

■ Testing machinery

■ Wind turbines

A Sun Phototnics

Product Description :

"ATOM Micro-Diameter Drill" Challenges Semiconductor Ultra-Micro Hole Processing Technology

In response to the problem of micro-hole processing in chip packaging testing, ATOM has launched multiple solutions. The following two series are highly respected in the industry:

ADR Standard Series Drill

The minimum diameter of the ADR series can reach Ø 0.02mm, and the diameter tolerance is less than −0.005mm. It is suitable for micro-hole processing of materials such as steel, non-ferrous metals and resins. Yuewei Technology is the general agent of ATOM in Taiwan and China, with sufficient inventory and efficient delivery services.

ADR-SV Standard Coated Series Drill

The ADR-SV series drill has a wear-resistant FCS coating and is suitable for micro-hole processing of soft steel and high-hardness steel (HRC50). This series is designed with a wider chip groove and polished on the edge of the cutting edge, which significantly improves the chip removal smoothness and processing quality, and effectively extends the life of the drill.

Advantages and features of "ATOM micro-diameter drill" in semiconductor manufacturing

1. Extremely high precision

ATOM micro-diameter drill can achieve extremely high drilling accuracy on materials such as aluminum alloy and engineering plastic (PEEK). This is crucial for socket test sockets, because ICs are getting smaller and smaller in the process of rapid technological development. How to achieve the hole position accuracy required by customers in the manufacture of socket test sockets requires not only the stability of machine tools, but also the support of tools.

2. Excellent hole wall roughness and hole burr suppression

The hole wall roughness and hole burr suppression of micro-diameter drilling are directly related to the quality of the hole. Whether it is a blind hole (Blind Hole) or a through hole (Through Hole), ATOM micro-diameter drill can achieve smooth, burr-free, flawless hole wall roughness and hole, which helps product yield and remove burrs after processing.

3. Low loss and high production efficiency

When drilling, high-speed machining machines cause the temperature of the drill tip to rise due to the high speed, which leads to drill wear. ATOM micro-diameter drills use high-quality all-tungsten steel raw materials as the base material to achieve ultra-long tool life, thereby saving the problem of equipment stagnation due to tool change.

4. Full size and complete inventory

As the exclusive agent of ATOM micro-diameter drills, Yuewei Technology imports a full range of Japanese size series inventory, from Φ0.03~Φ1.00, with a standard inventory of Φ0.01, and a diameter ratio of 5D/10D/15D/20D, uncoated ADR or coated ADR-SV are all in stock in Taiwan, meeting the needs of today's increasingly shorter delivery time, and achieving the convenience of 2-day delivery.

5. Customizability

ATOM micro-diameter drills can be customized according to the needs of specific applications. Whether you need a stage forming drill, a high-diameter drill, or a water-out drill, you can customize it according to the drawing.

【Contact Information】

Tel: +886-2-26327601

Fax: +886-2-26327604

Line@ : https://line.me/R/ti/p/%40332yetoa

Website: https://asun-photonics.com/

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

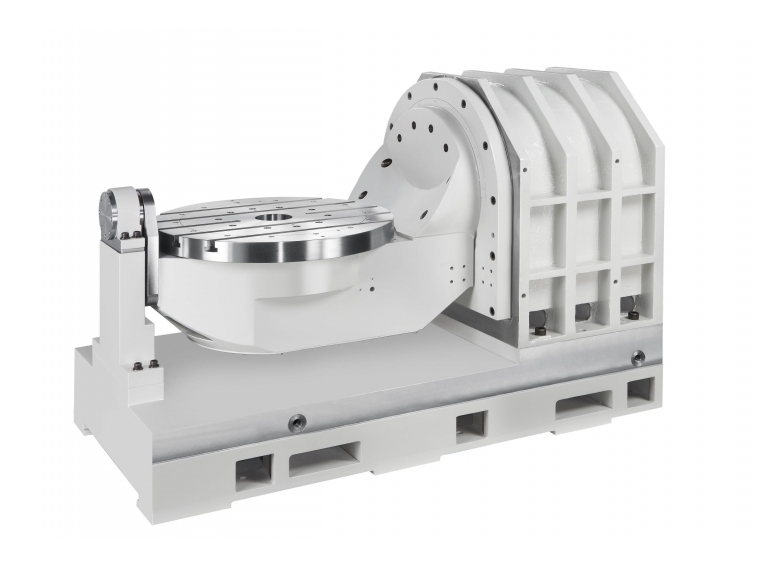

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

BLUM PRODUCTION METROLOGY CO., LTD.

Product Description :

• Measuring speed up to 3 m/min

• Precise, non-lobing touch characteristics

• No-wear, optoelectronic measuring mechanism

• Use of two measuring systems with one IR receiver

• Extended battery life

• Precise measurement even with coolant

• Proven and robust design