Theme

Digital Transformation

Green Transformation

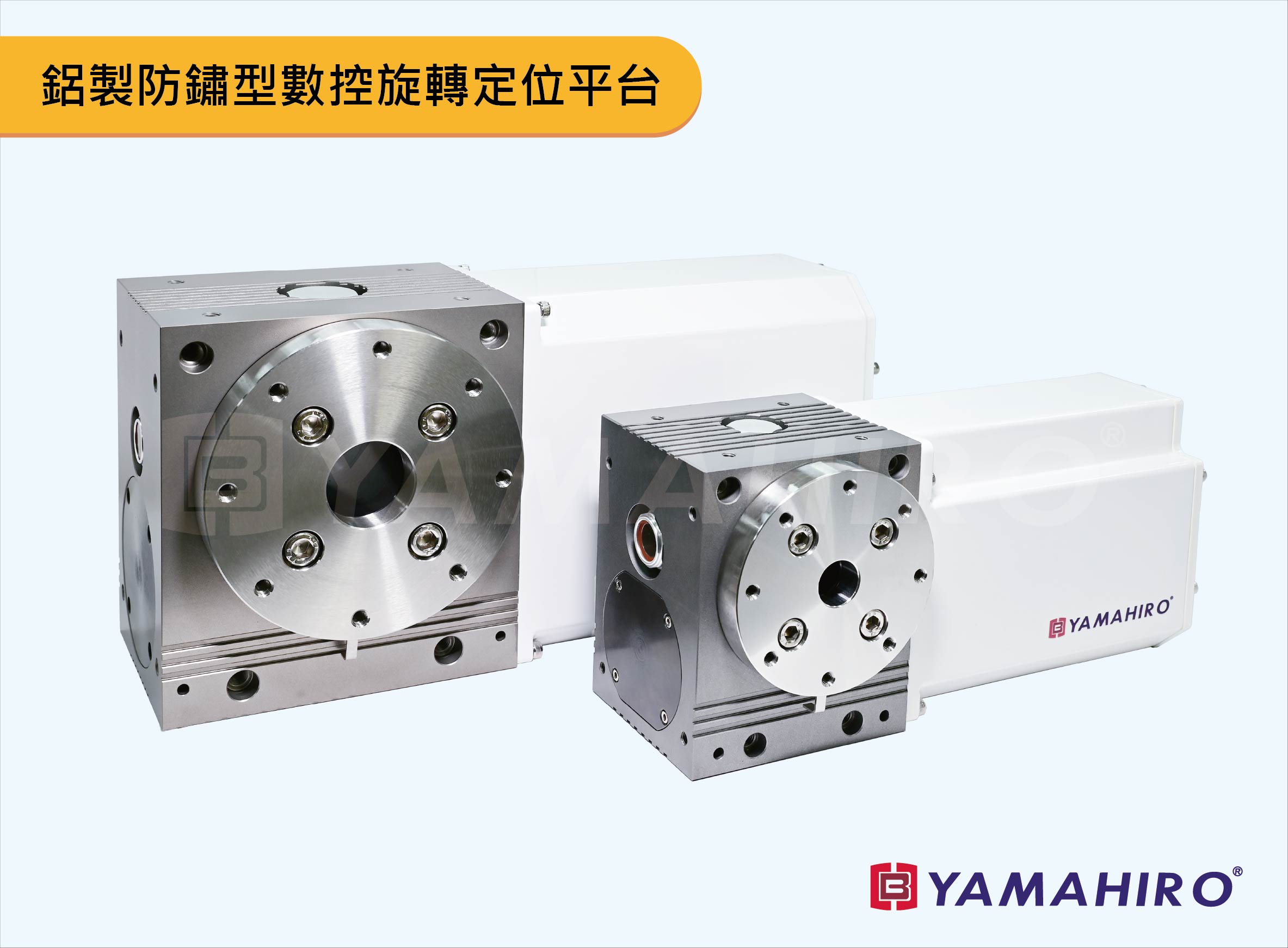

HER BAO MACHINERY CO., LTD.

Product Description :

★ Features: High self-locking force, high precision, lightweight, optimal multi-functional CNC rotary positioning platform.

★ Applications: CNC multi-head carving milling machine, automated multi-position applications, grinding machine Z-axis application, multi-spindle drilling machine application, polishing equipment application, semiconductor turntable application... and so on.

YI CHANG MACHINERY CO., LTD.

Product Description :

Regardless of whether you use semi-automatic drilling machines, manual tapping & drilling machines, pneumatic machine, hydraulic machine or gear type machine, they can be assemble with multiple spindle head and servo slides to greatly enhance work efficiency while meeting diverse production needs.

This machine type combines mature semi-automatic technologies such as pneumatic, hydraulic, and gear type systems, assemble with multiple spindle head and servo slides, expanding the application range of drilling and tapping machines and making them more adaptable to various production requirements.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

PALMARY MACHINERY CO., LTD.

Product Description :

For various eccentric circle or non-round shape workpieces grinding purpose, PALMARY develop CNC Cylindrical Grinder Cam Type with CAD/CAM software for easily transfer from workpiece drawing to grinding program. The workhead could offer precise angle control upto 0.1 micron resolution due to the C axis has accurate angle encoder. The infeed axis is driven by linear motor with linear guideway & close loop linear scale, it could avoid the backlash in order to reach high machining precision. Also, it could prevent the reaction force causing by linear motor under the large acceleration and deceleration motion, it could stabilize the grinding process.

Fulson Industrial Co., Ltd

Product Description :

This high precision surface and form grinder has been specially developed and improved in recent years.

The tool cabinet in machine base is specially designed for operator’s convenience (618m).

The interlock between electrical cabinet door and power supply is established to ensure safe operation.

The maximum distance from table surface to spindle centerline is 18" (450mm) which provides more clearance for grinding.

The sping loaded type table travel stops will dampen theovertravel caused by abnormal operations (618m).

The optimum span of double V crossfeed guideways is designedbased on bending moment, kinematics supporting force.

All essential castings are mode of high grade of meehanite castiron that is stress relieved through annealing to eliminateinternal stress.

With the greatest stiffness and stability of the castings, this machine is suitable for both precision surface grinding and formgrinding .

This grinder is offered with one-full-year limited warranty formechanical and electrical parts .

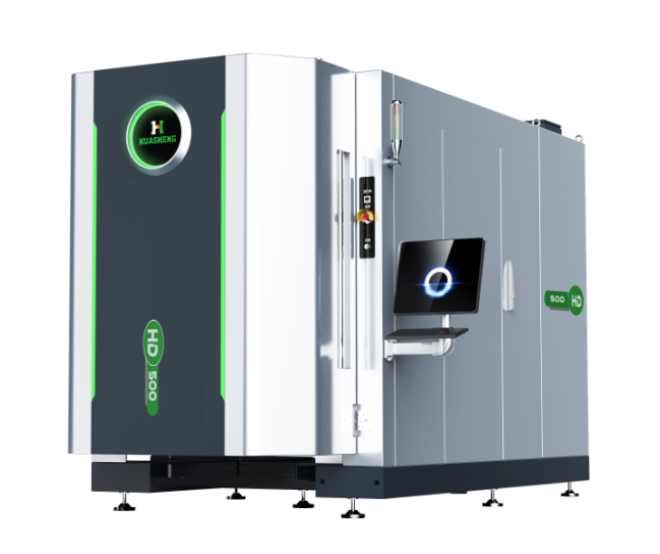

Guangdong Huasheng Nanotechnology Co., Ltd.

Product Description :

HD500 融合了 Arc 与 HiPIMS 两种技术的核心优势,构建出高效、灵活的复合涂层解决方案。

Arc 技术通过优化等离子体阳极设计,显著提升薄膜性能,液滴更少、表面更光滑;同时配合等离子体辅助电源与快换式阴极磁场结构,可有效提升靶材利用率、降低运行成本,并灵活匹配多种涂层材料,其隐藏式引弧结构也使设备运行更加稳定、维护更便捷。

HiPIMS 技术则支持多种溅射模式,满足更丰富的材料与工艺需求,在实现高离化率的同时保持较高沉积效率,涂层内应力更低、结合力更强,并可更灵活地平衡薄膜硬度与残余应力之间的矛盾。

依托华升全新复合涂层技术平台,HD500 构建了高离化溅射与电弧工艺深度融合的复合工艺体系。基于该技术制备的薄膜具备更广泛的适用性,尤其在不锈钢、钛合金等难加工材料领域展现出明显优势,可显著提升刀具与零部件的使用寿命。

同时,该技术体系具备良好的拓展潜力与工艺灵活性,既能满足小批量涂层生产需求,也适用于工艺研发与技术验证场景。

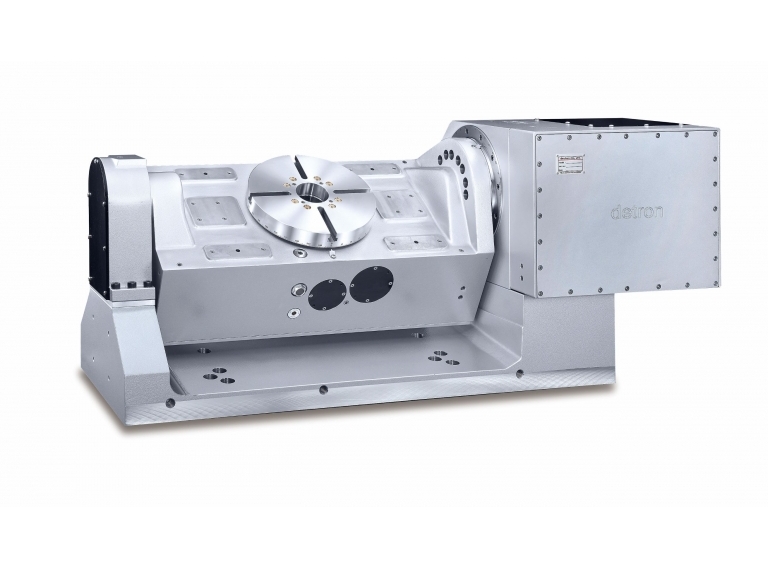

TONGTAI MACHINE & TOOL CO., LTD.

Product Description :

1. Excellent ultrasonic control technology, able to automatically complete frequency scanning and power settings efficiently.

2. Tool vibrates periodically (15~45 kHz), reduces cutting resistance and enhance surface quality

3. 20,000 rpm high speed spindle, supports standard BBT-30 tools.

4. Ultrasonic assisted machining can reduce cutting resistance and process temperature rising, to extend the tool's lifetime.

5. Ultrasonic assisted machining can reduce the roughness from processed surface, to reduce the time for polishing.

6. Can reduce the burr existing after processed hard and brittle material.

7. Can do micro-hole processing for hard and brittle material.