Theme

Digital Transformation

Green Transformation

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

RenAn's operation simulation workstation is a physical simulation with 3D graphic, showing the cutting and machining process.

[Save consumable cost]: There is no need to worry about the expenditure of consumables, and it will not be affected by pollutants such as waste materials and oil and gas.

[Safety]: Advanced 3D simulation and CNC virtual machine make high risk CNC operation without any danger.

[Smart learning]: Like training the pilot using flight simulators, we use CNC simulator to train the students or operators to be the machinist. Its industrial panel remains the same functionality as real machine that students can practice constantly to accumulate hands-on operation skills.

The controller series of simulator: Fanuc, Siemens, Heidenhain and Mitsubishi.

Turning, Milling, TurnMill, 4 axis, 5 axis.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

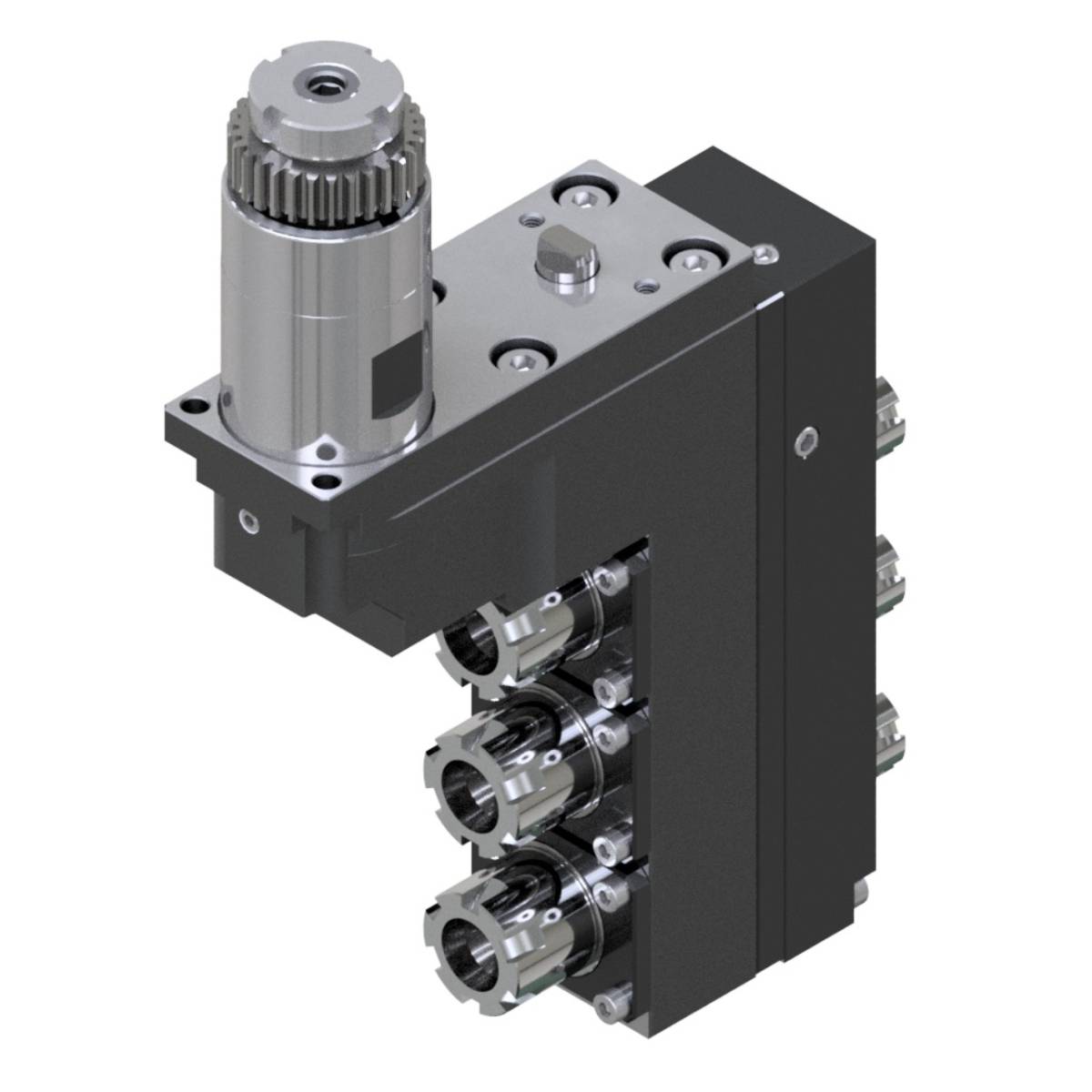

●精密鉸孔神器-浮動鉸刀柄,可解決以下問題:

1. 孔的直線行差

2. 鉸刀不耐用

3. 孔的尺寸擴大,尺寸精度達不到要求

4. 孔的中間大,兩頭小,圓柱度達不到要求

5. 內孔表面粗糙度達不到要求

6. 大批生產時無法保證孔徑尺寸的一致性 。

●浮動鉸刀柄的特點:

1.可透過360度浮動讓鉸刀對準下孔徑,避免對不準而造成擴孔或縮孔

2.徑向振幅抑制在5μm以下

3.提高鉸孔光潔度

4.彌補車床公差,提高鉸孔精密度

5.提高鉸孔的直線度和圓柱度

●浮動鉸刀柄可應用加工機械:鑽床、立式加工中心、研磨機。 可夾持工具:鉸刀、滾光刀

**產品連結→→https://www.songgia.com.tw/tw/products/other-tools/floating-reamer-holder

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. Our main economical machine type with high processing efficiency, the price is more affordable than swiss type, it's an entry models for CNC lathe.

2. The box way configuration is suitable for medium/heavy cutting. The base of the fuselage is cast and formed. It is relatively strong and strong.

3. With X/Z axis large travel design, wide of span, more robust and stable processing, easy to tool arrangement.

4. Can be used with the bar feeder for automatic processing without interruption, and can also be customized for single-piece automatic feeding.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

PJ-20V0 is a surprising design. In addition to the dead corners of the bar feeder, there are also many spaces that easy to ignore, used by customers to pile up the stuff and lose the value of use. The idea of PJ-20V0 revitalizes these spaces and is no longer limited to 2D imagination, also to evolve to the concept of 3D space. This system provides a powerful and compliant function system for users continuously. Using for continuous variable volume (pressure), saving the electricity cost and the time of the adjusted pressure. Suitable for the Swiss Lathes and gun drilling.

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Tungsten Carbide Blade Tool Processing

1. Excellent grinding ability, significantly reducing spindle load, save processing time and cost.

2. Tough texture and wear resistance characteristics to achieve the maintenance of tool dimensional accuracy.

* Processing Material | Tungsten Carbide

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

This model can work with two axes gantry loader to transform CNC lathe be automation which is in order to accomplish automatic catching single blank material, uploading, unloading and clamping manufacture progress to increase physical labor productivity.

The most advantage is we can stand on the customer’s machining demand to choose the different types of feed stations.

MANFORD MACHINERY CO., LTD.

Product Description :

With linear guideways on X and Z axes and 30M/Min rapid traverse, SBL series is absolutely an ideal solution for high-speed turning applications.

Features

● 30゚slant bed structure.

● Meehanite cast iron for all structural parts.

● Hardened and ground ballscrews for precise traversing and consistent machining accuracy.

● Fully enclosed splash guard ensures a safe and clean working environment for operators.

LEADWELL CNC MACHINES MFG., CORP.

Product Description :

Spindle nose A2-6 with 8” inch chuck for both spindles. The bar capacity of the main spindle is up to 52mm. Spindle uses high-power built-in motor with a maximum torque of 292Nm which for heavy cutting and surface milling operations. The capacity of the Y axis is ±50mm, which allow offset processing and increase the speed of milling.

Max. swing: 790mm

Max. turning diameter: 300mm

Max. turning length: 770mm

Bar capacity: 52mm

X1-axis travel: 235+15mm

X2-axis travel: 220+10mm

Z1-axis travel: 770mm

Z2-axis travel: 790mm

B-axis travel: 770mm

Y-axis travel: ±50mm

Spindle speed(Main/Sub): 4500rpm

Spindle nose(Main/Sub): A2-6

Spindle motor power(Main/Sub): 25kw

Number of tool stations: 16T

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.