Theme

Digital Transformation

Green Transformation

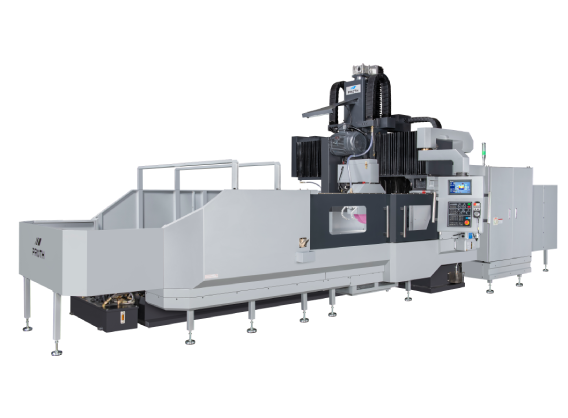

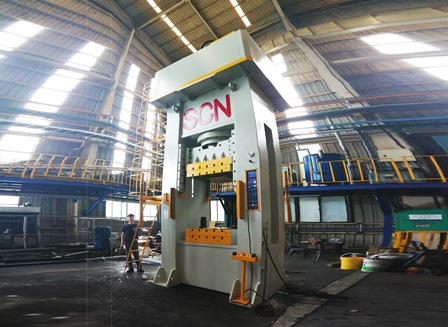

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Hydraulic System : Two single-acting hydraulic cylinders are used with their piston rods anchored at very specific positions.This enhances rigidity and creates a very stable table motion; table float is eliminated.

3. Grinding spindle : The precision high rigidity spindle is of a cartridge type design. This provides for easier accessibility and service when maintain is needed.

4. Upgradable CNC numerical control.

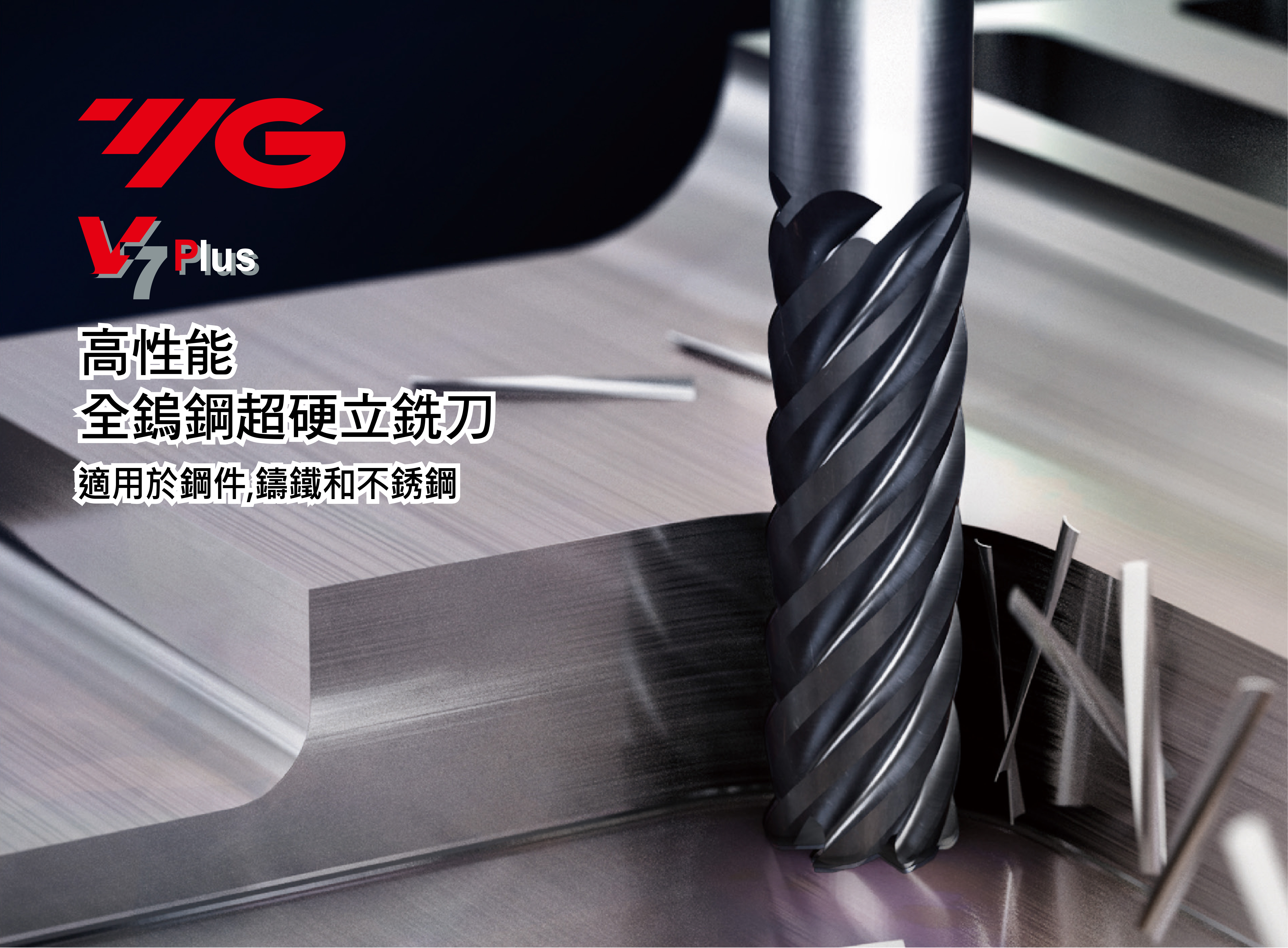

SHARPMAX TOOL INC.

Product Description :

● Periodic cutting stree is effectively suppressed by

continuously changing outer teeth spacing,allowing

for chattering control.

● Excellent anti-vibration performance compatible in a

wide variety of milling for exotic alloys including

SUS,inconel,and Titanium.

● Reduces chattering for high-speed and high-feed

cutting.

● Ultra-smooth coating with significantly

improvedcoating hardness and heat resistance

improves tool live in heat resisitive ally maching.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The WTS series combine with double turret, double spindle and double Y axis. Both of 16-station power turrets are available to be equipped of BMT-55 tooling system. The WTS has E-axis shifting function, it allows the sub spindle to move up and down to provide independent working area.

The WTS-52Y2M provide ∅51mm maximum bar feeding dia. and it can install fixed tailstock above the sub spindle when using collet, it allows to keep the longer workpiece dynamic balance with the main spindle and improves precision during machining. The WTS-65Y2M bar capacity up to ∅65mm, the A-6 spindle nose can install larger size chuck and the spindle motor upgrade to higher torque and bigger power.

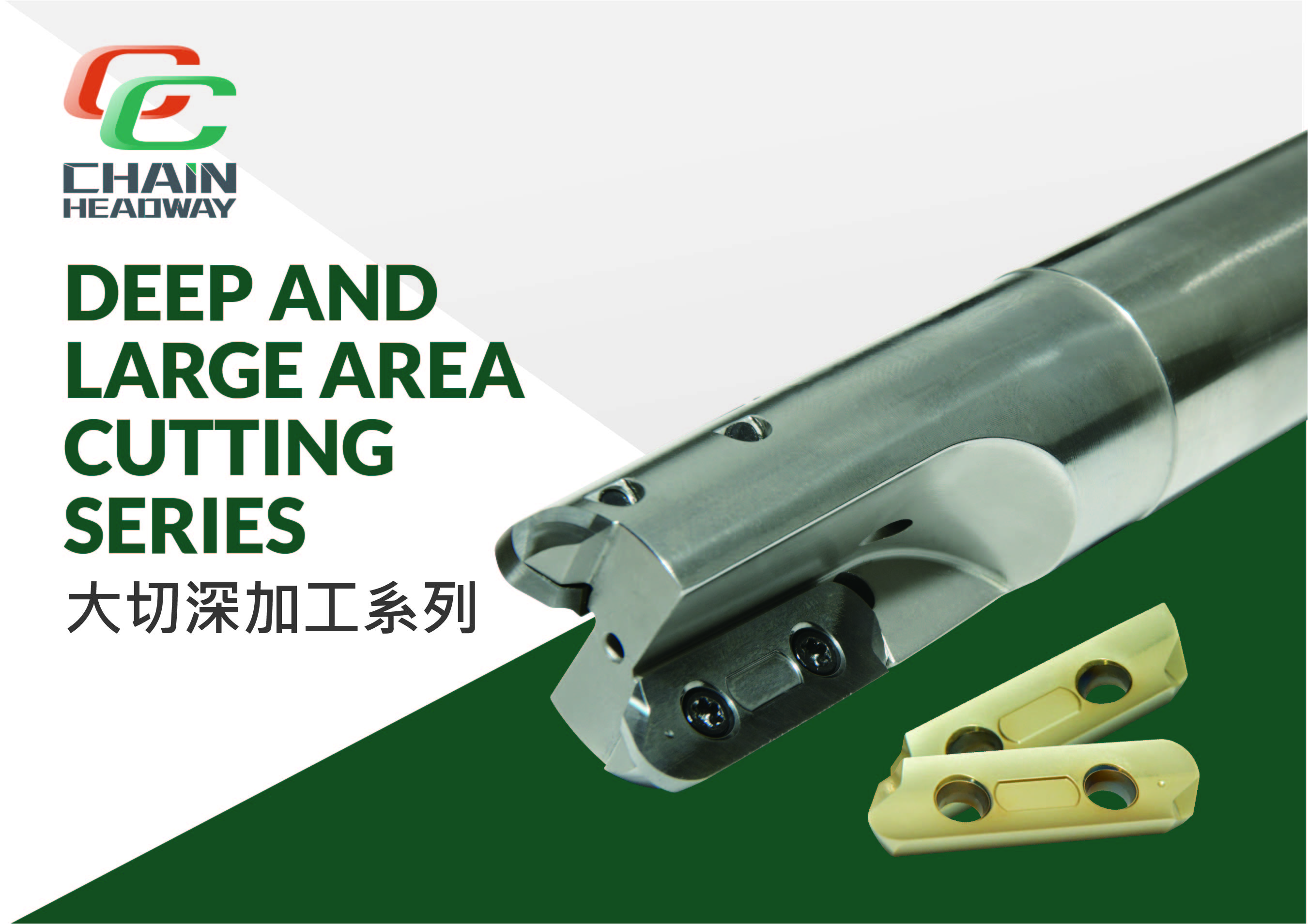

CHAIN HEADWAY CO., LTD

Product Description :

AECX32T3 Deep-Cut Long-Edge Hurricane Insert|High-Efficiency Solutions for Professional Cutting Tools and Indexable Inserts

In precision machining fields such as aluminum alloys, molds, and automotive components, stable cutting performance and superior surface quality are the keys to production competitiveness.

The AECX32T3 Deep-Cut Long-Edge Hurricane Insert combines high-precision edge design with innovative coating technology, specially engineered for deep cutting up to 30mm, achieving seamless surface finishing with no tool marks.

Core Advantages of AECX32T3

Seamless Surface Finish — No Tool Marks

With its precisely designed cutting-edge radius, the AECX32T3 eliminates tool transition marks during long-distance milling.

Tests have shown that the machined surface is smooth and refined, significantly reducing the need for post-polishing and finishing time.

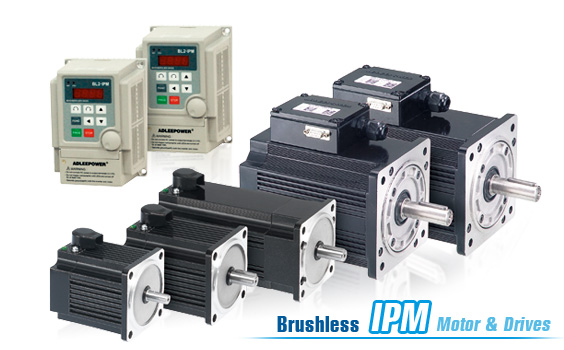

ADLEE POWERTRONIC CO., LTD.

Product Description :

Product applications:

Internal & External grinder 、Conveying equipment、Coffee roasting equipment、Centrifugal equipment、Polishing equipment、Emulsifying machine、Glass edge grinder、Auto polisher grinder, etc.

Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

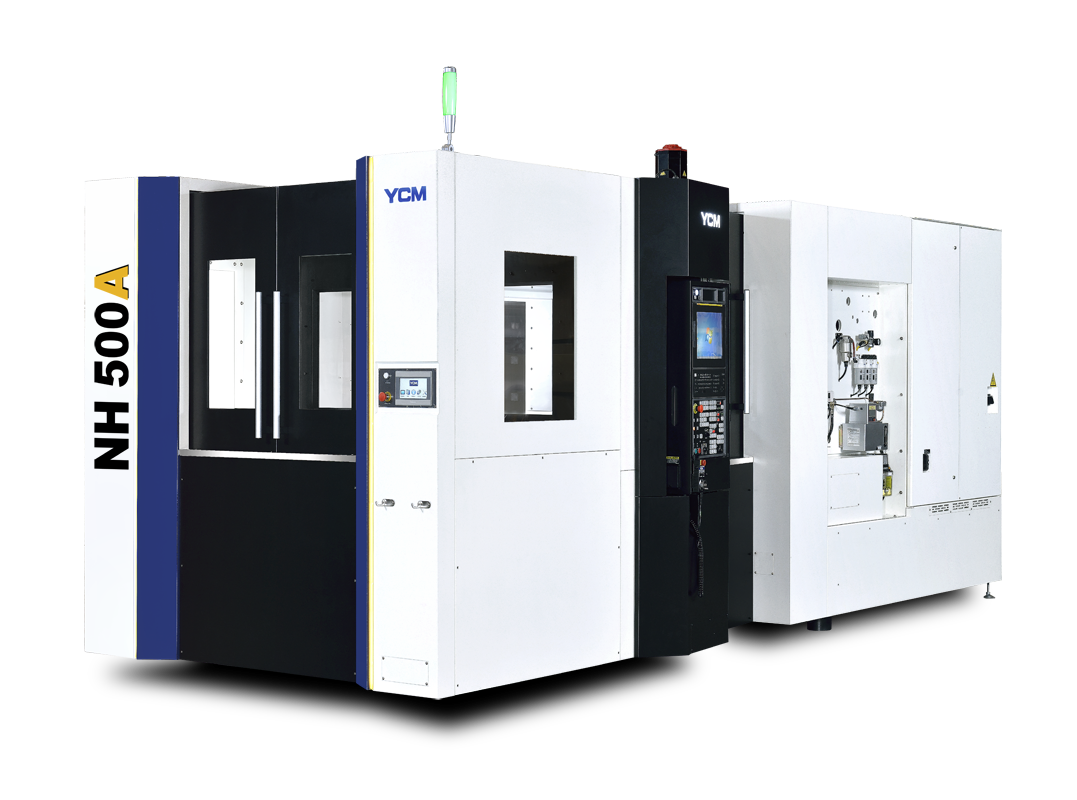

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

High rigidity and high accuracy NH500A provides the best solution for automotive, precise and mechanical parts industries.

■ High rigidity T-base foundation with rib construction

■ One-piece casting spindle headstock and dual-wall column design

■ Powerful Built-in spindle with Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life

■ High precision roller type guideways on all axes

■ High precision pallet indexing system.