Theme

Digital Transformation

Green Transformation

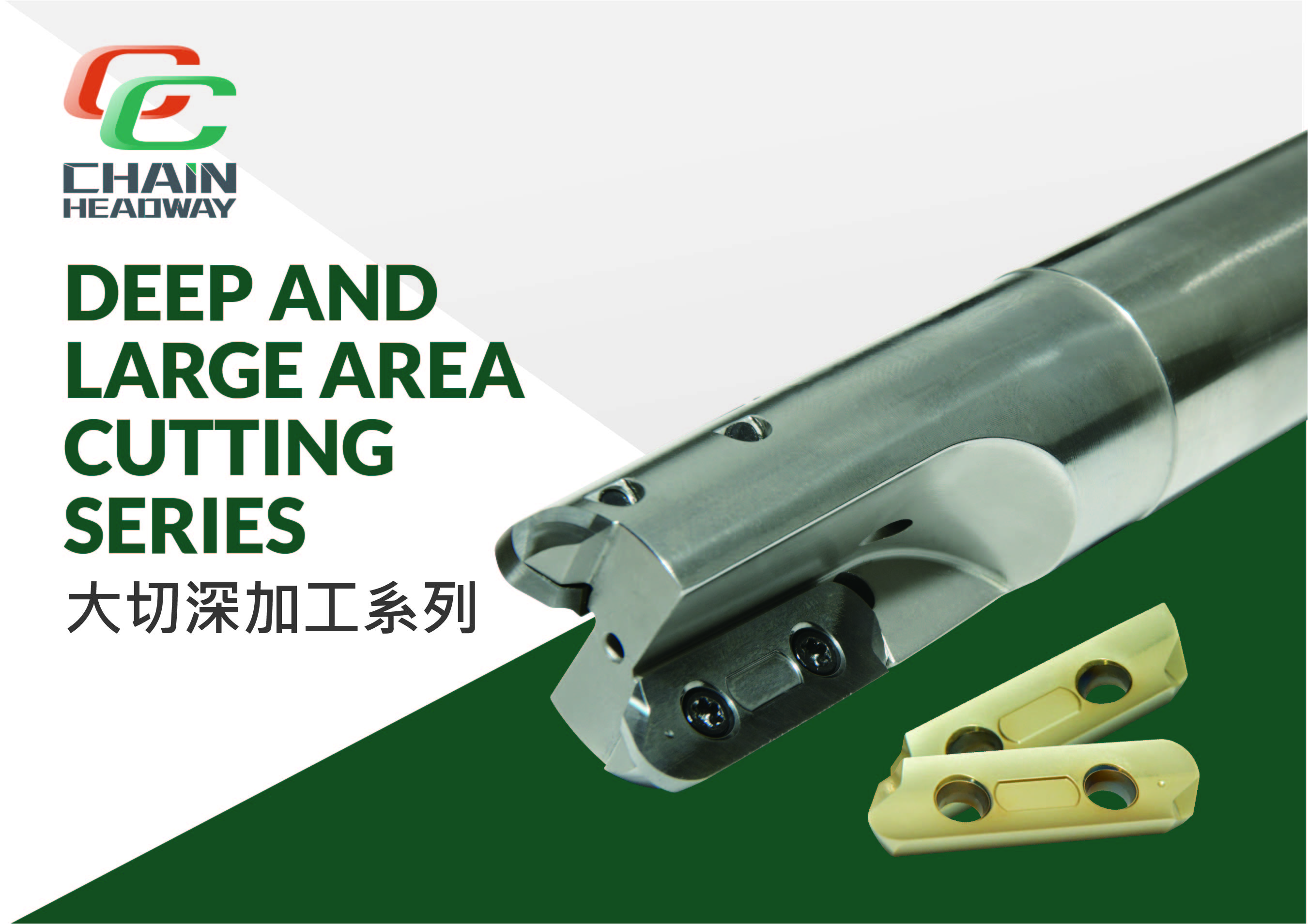

CHAIN HEADWAY CO., LTD

Product Description :

AECX32T3 Deep-Cut Long-Edge Hurricane Insert|High-Efficiency Solutions for Professional Cutting Tools and Indexable Inserts

In precision machining fields such as aluminum alloys, molds, and automotive components, stable cutting performance and superior surface quality are the keys to production competitiveness.

The AECX32T3 Deep-Cut Long-Edge Hurricane Insert combines high-precision edge design with innovative coating technology, specially engineered for deep cutting up to 30mm, achieving seamless surface finishing with no tool marks.

Core Advantages of AECX32T3

Seamless Surface Finish — No Tool Marks

With its precisely designed cutting-edge radius, the AECX32T3 eliminates tool transition marks during long-distance milling.

Tests have shown that the machined surface is smooth and refined, significantly reducing the need for post-polishing and finishing time.

HISEN ENTEPRISES CO., LTD.

Product Description :

The crystal power supply device uses high-power IGBTs to form a parallel inverter circuit.

The horizontal workstation is driven by a servo system and linear guide rails, ensuring stable travel speed. The transmission rollers are made of SUJ2 material, with weekly heat treatment and hard chrome plating, resulting in excellent strength and flatness. The system monitors the processing data of each workpiece to ensure consistent output quality.

The quenching liquid cooling system's water tank and piping are made of 304 stainless steel, and the system can monitor the water level, pressure, temperature, and flow rate.

LNS TAIWAN CO., LTD.

Product Description :

The SL65 S is an entry-level alternative for spindle length bar stock feeding. The SL65 S is designed for simple applications, especially for standard production parts, and for medium and large production runs.

●The SL65 S permits easy adjustment of the diameter.

●The operator-friendly remote control ensures the interaction between the bar feeder and the lathe.

●The SL65 S retraction system facilitates access to the lathe without compromising the precision of the alignment.

SESAME MOTOR CORP.

Product Description :

The stainless steel planetary gearboxes are specially developed and constructed for use in food, pharmaceutical, chemical, biotechnology, aerospace, anti-magnetic applications and those environments require corrosion protection exist. Smooth appearance and permanent laser engraving label to provide outstanding corrosion resistance in washdown environments. Customized requirements such as high level IP protection or surface treatment are available to apply high temperature and pressure washdown or hygienic environments.

Spiral bevel speed reducers (gearboxes) are ideal for use in applications that require high dynamic motion control. Compact and rigid gearbox design ensure good performance with space and weight efficient at the same time. Low noise, low vibration, lubricated for life and IP65 sealing benefit virtually maintenance-free operation for 20,000 hours. They are provided in seven sizes with flange or shaft inputs/outputs. Servo motor input speed up to 8,000 rpm. Multi flange or shaft outputs in standard backlash less than 6 arc-minutes. Maximum gear ratio 500:1, maximum frame size 210 mm. A wide range of motor adapter are available for installation to virtually all servo motors.

Feel free to contact us for further information. https://www.sesamemotor.com/contact/en/

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"ECHAINTOOL is a well-known leading brand in Taiwan. It is the leading manufacturer of professional cutting tools and cooperates with the world's leading brands of cutting tools. It has multiple cutting tool products and sufficient inventory to meet the different needs of customers. The quality products are all made in Taiwan, and have won the ""Taiwan Excellence Award"" and ""Excellent Design Award"" and passed the IS0 9001 certification, which is directly recognized by many customers from the world of aerospace, automotive and mold companies.

Adhere to the promotion of our own brand ""ECHAIN"", mainly develop and manufacture all kinds of discarded cutting tools (carbide end mills, inner/outer boring tool holder, threading tool, various milling cutters, drilling tool, hole boring cutter, rapid drills, etc.) and related components are widely used in CNC lathes and milling machines for various precision machines.

The carbide end mills developed by the ECHAIN team are all produced by the German WALTER five-axis machine to obtain the best quality and effectively meet the needs of the industry. "