Theme

Digital Transformation

Green Transformation

PRECISION MOTION INDUSTRIES, INC.

Product Description :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

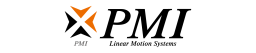

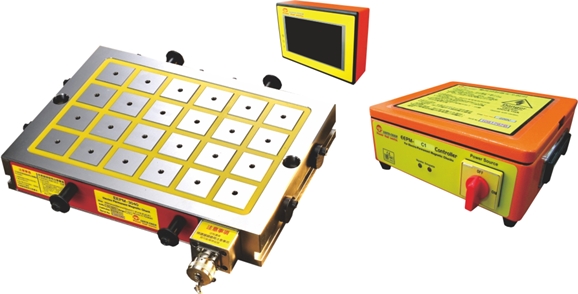

EARTH-CHAIN ENTERPRISE CO., LTD.

Product Description :

1.Suitable for CNC Vertical machining center (Can do 5 sides machining)

2.Suitable for thin, small , medium and large workpiece on varies cuttingmachining.

3.Suitable for thin, small , medium and large workpiece of the drilling and finishing machining.

4.Minimum size of workpiece required as 4 alternate magnetic square poles and above contacts is necessary for

optimum clamping.

5.More functions for cooperate with Induction Block and Spring Block.

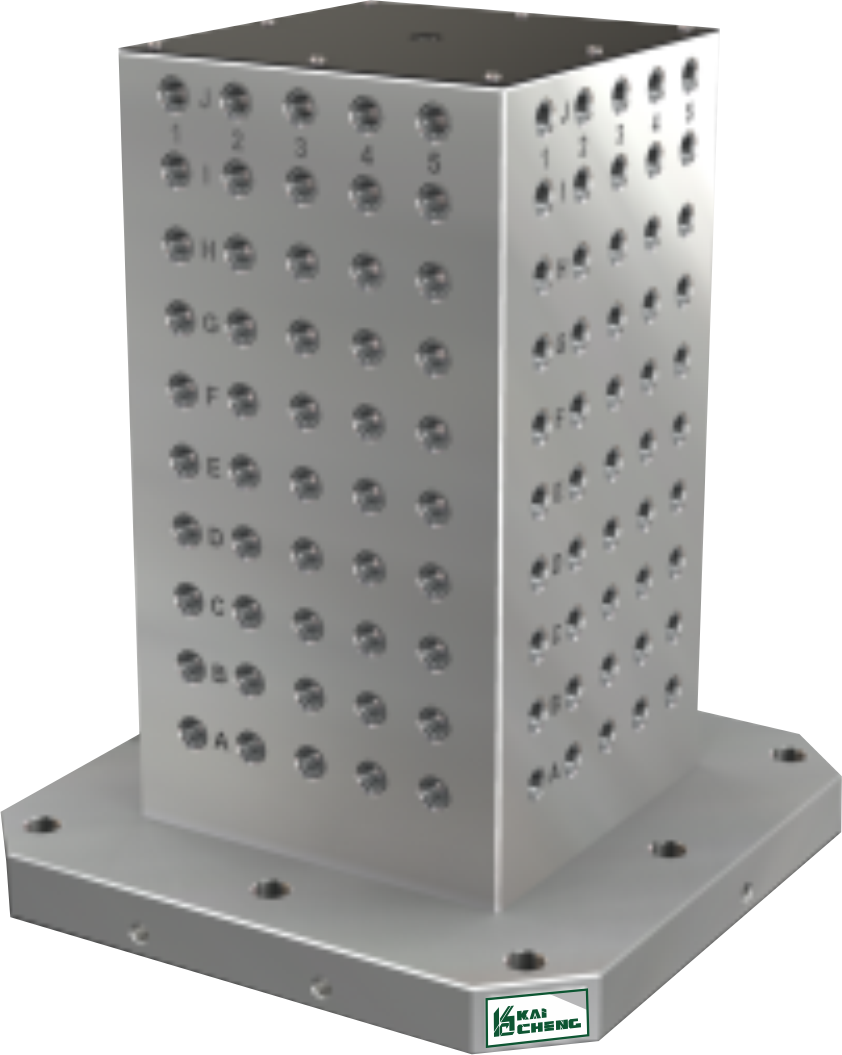

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■ Full series of inverter compressors are smooth start. There is no-start instantaneous high current and saving power more than 33%.

■ Unique design of multi-function LCD panel and it's provides -0.10°C temperature control stabilization.

■ There are 15 malfunction protection to ensure normal operation of cooler.

■ When low heating load is happend,the cooler will operate in low load mode and combined accurate temperature control and energy saving.

■ Groove recessed panel design is reducing oil mist infiltration into electrical control unit.

■ Using high-efficiency heat exchanger to enhance cooling efficiency.

■ Using high-efficiency environmental refrigerant and without pollution.

■ Up-to 95% materials of machine are recyclable and eco-friendly.

OSCAR E.D.M. COMPANY LTD.

Product Description :

ZX SERIES

• Economical design with manual control for X and Y axes and AC servo motor control for the Z axis.

• Equipped with a handheld control box screen for quicker mold centering and electrode edge detection.

• Since the X and Y axes use manual handwheels, OB orbit functionality is not supported.

TAIWAN SPINFLO CO., LTD.

Product Description :

-Accuracy temperature Control at ±0.1℃, solve machine tool maker and manufacturing reduce machine’s life that running long time and high temperature.

-Continue using high-accuracy control let machines get more accuracy and do perfect products.

-Not only good performance but also can get high efficacy in different area.

GUEY CHERNG TRADING CO., LTD.

Product Description :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

YINSH PRECISION INDUSTRIAL CO., LTD.

Product Description :

YINSH PRECISION IND . CO ., LTD . specializes in the production of superfine balanced locknuts for high speed machine tool spindles. SBL series is designed for all configurations of internal and direct drive spindles. Inner threads, outer skirts, clamping and trailing rims are all precision ground. Coupled with balanced adjustment screws, these locknuts stay perfectly balanced at high speeds. Made of high grade SCM440 alloy steel and hardened to HRC 48°-52°, rigidity and precision at high speeds is given. All locknuts can be fitted with adjustment screw hole screw-in plugs(option), eliminating high frequency noise and subsequent vibration.

Alpha Precision Instrumentation Corp.

Product Description :

HandySCAN 3D PRO is an industry-leading portable metrology-grade 3D scanner that uses patented technology to precisely and repeatedly capture complex surfaces in any environment. Equipped with the Scan-to-CAD Pro software module, it supports rapid conversion of scan data into CAD models, enhancing workflow efficiency. With high accuracy and fast measurement speed, it helps you quickly complete reverse engineering, quality inspection, and design modifications. Its compact and lightweight design makes it easy to carry, and its intuitive operation simplifies and stabilizes the measurement process. Whether in the factory or R&D lab, you can quickly obtain high-quality 3D data to help your company accelerate product development, reduce costs, and achieve innovative breakthroughs.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity