Theme

Digital Transformation

Green Transformation

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

We customize CNC MPG pendant encoder, comprise antistatic protection, reversed voltage protection from DC5V to 24V. Rugged model with IP67 dust-proof, oil-proof and waterproof, ergonomics design is much easier to use and smooth handling. Depending on actual needs, axis and multiplication selections can be set; function buttons, emergency stop switch, enable switch, indicator light and wire length are also optionally available.The MPG pendant handwheel is easy to install with multi-conductor cables, and can print the company logo on the manual pulse generator wheel cover. Manual pulse generator box, MPG box, Handle box MPG can choose 100 PPR pull-up, 25 PPR pull up, 100 PPR line driver, 100 PPR open circuit... etc.. Support CNC system like FUNAC, SIEMENS, MITSUBISHI, FAGOR, HEIDENHAIN, LNC, SYNTEC, GSK and other industrial CNC machines.

DKSH Taiwan Ltd.

Product Description :

EVALED® RV F is the line of mechanical recompression evaporators designed to reach the highest level of reliability in heat transfer, with minimum impact in terms of fouling and scaling.

High efficiency forced circulation shell & tube heat exchanger with horizontal tubes allows wastewater concentration up to the salts solubility limits and to manage also suspended crystals.

Wastewater is constantly treated: the distillate and the concentrate are continuously separated and then simply discharged through a pump. Heat is recovered by cooling the two outlet streams using the inlet effluent.

Available in different materials to treat different effluents containing dissolved salty, organic compounds and even the most aggressive salted wastewater (high chlorides content), produced by various industries.

The MVR is the lowest energy consumption evaporation technology.

• Maximum water recovery;

• Effective reduction of waste to be disposed of;

• Modular and flexible;

• Intuitive HMI;

• Plug & play;

• Minimum labour.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

■ The unique IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

■ Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

■ High precision rotary encoders in the B and C

axes as a standard feature, allowing for the most demanding machining accuracies.

■ ø650 mm table provides stable machining performance with a wide machining area and trunnion support.

TAIWAN SPINFLO CO., LTD.

Product Description :

-Accuracy temperature Control at ±0.1℃, solve machine tool maker and manufacturing reduce machine’s life that running long time and high temperature.

-Continue using high-accuracy control let machines get more accuracy and do perfect products.

-Not only good performance but also can get high efficacy in different area.

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.

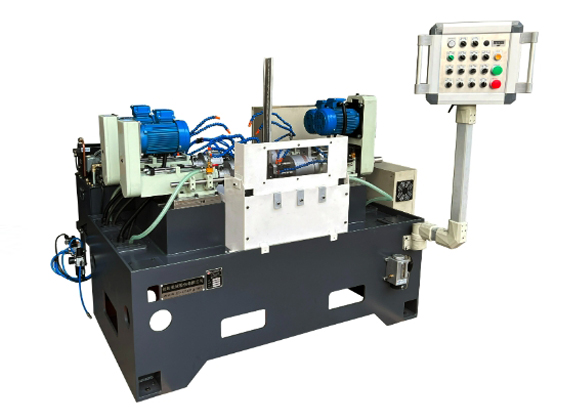

YI CHANG MACHINERY CO., LTD.

Product Description :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

YK series is designed specially for small and high precision parts with powerful processing capacity, stable quality and accuracy. It is the best choice for various manufacturers of automotive and motorcycle parts, electronic parts, instrument parts and medical equipment parts.

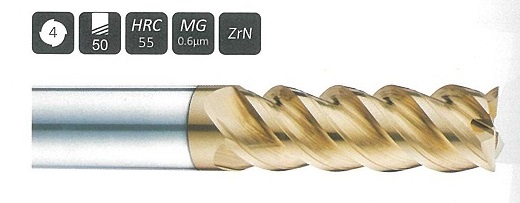

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

MANFORD MACHINERY CO., LTD.

Product Description :

CNC Vertical Lathe

●The first spindle has C axis function, allowing the machine to perform turning milling complex operations. The second spindle accommodates fixed seat tool and live tool.

●The column is a symmetrical box type high rigidity structure.

●With the use of a high precision gearbox on CF axis for high positioning accuracy combined.

●Box ways on X/Z axis.

●12 positions armless type tool disk.

●Two-step speed change for table rotation.