Theme

Digital Transformation

Green Transformation

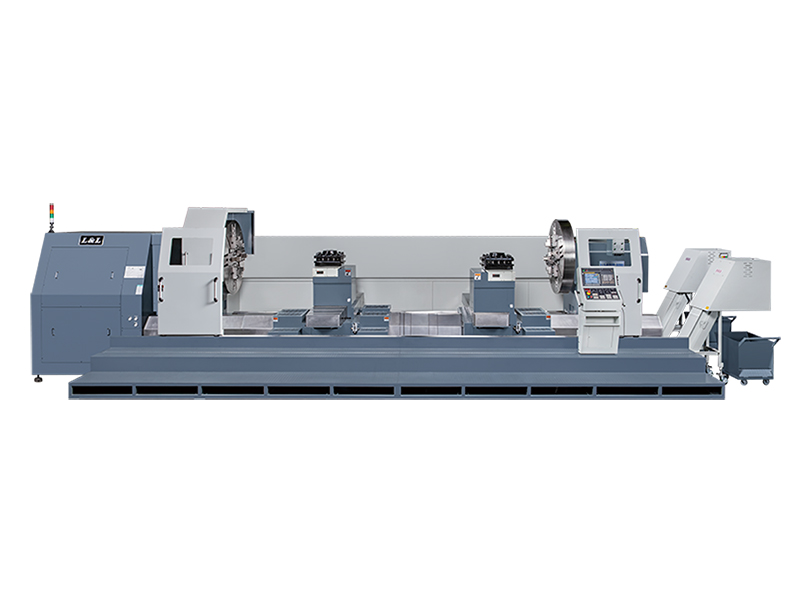

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

Smart heavy-duty multi-axis composite cutting machine, LLS-M, for the target industry market (oil industry, aerospace industry, steel industry and rubber and rubber industry), achieved ALL Processes In One Machine to reduce the clamping and shortening process, with precision and life management The intelligent machine, constructing the machine information management platform and man-machine management interface, integrating the computer numerical controller, the smart set-top box and the cloud product life cycle database, providing relevant data and data through artificial intelligence calculation analysis and application, reaching the machine Accuracy and life and performance improvement, and applied to the virtual reality pre-sales service system, the use of the real-life expansion after-sales service system to build a smart mechanical value service chain.

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Electronics is a leading brand of demagnetizers in Taiwan. It has nearly 40 years of experience in designing and manufacturing demagnetizers. More than 20 kinds of demagnetizers have reliable work and stable performance and provide a full range of professional solutions for your demagnetization / demagnetization needs.

CHAIN HEADWAY CO., LTD

Product Description :

The Art of Cutting — Tailored for You

PCD, CBN & Carbide Precision Inserts × Your Best Choice for Custom Machining Solutions

🎯 “It’s not about choosing our products — it’s about choosing our solutions.”

In today’s era of ultra-fast, high-precision, and high-efficiency machining, standardized inserts can no longer meet the challenges of diverse processes and materials.

Chain Headway offers more than just inserts — we deliver complete cutting solutions customized to your materials, equipment, and productivity goals.

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

Alpha Precision Instrumentation Corp.

Product Description :

NX CAD/CAM電腦輔助設計/製造,提供設計、模擬和製造解決方案,支援產品開發從概念設計到工程和製造分析。

Simcenter CAE為結構應力、噪音、電磁分析、熱流分析軟體,將系統模擬、3D CAE 和測試集於一身,優化設計更快更可靠地交付創新。

Teamcenter PLM生命週期管理系統,整合設計、製造、品管、銷售與維修等階段,產品開發整體程序中所有內部及對外溝通之相關資料與作業流程,透過Teamcenter所提供簡單易用之管理操作介面,讓企業使用者輕易地有效管理。

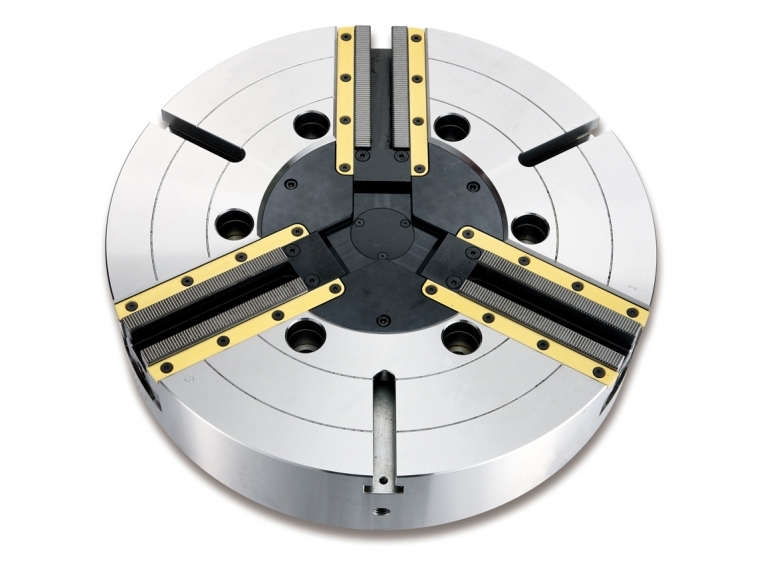

YANMECH Industrial Co., Ltd.

Product Description :

【J Series:】

1. Adapter Plates can be selected.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

3. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

4. Special specifications can be customized.

【L Series:】

1. Adapter Plates can be selected.

2. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

3. Special specifications can be customized.

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

Machines are equipped with a product visualization. This remote monitoring system can check the life of machines' parts, spindle servo axis and tool. This device can report potential problems in advance and solve them, reducing cost and preventing waste of operational time.

Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

. Processing size: 1300*900mm.

. Metal cutting configuration with Raycus fiber laser, laser wattage 1000W

. Non-metal cutting configuration 320W Co2 laser tube + professional thick plate cutting head

. Professional cutting system, "one-key switch button" on the machine, can easily switch between metal cutting function and non-metal cutting function.

. This equipment is specially designed for cutting a variety of materials, whether metallic or non-metallic.

. We combine the top-standard Co2 non-metal laser cutting machine configuration with the most popular fiber laser cutting configuration currently used in one machine

. Metal cutting head, 10mm focus Z axis direction adjustment, wide cutting range; excellent and stable beam quality, perfect water-cooled structure, advanced dustproof design, effectively avoid dust intrusion.

. Co2 non-metallic laser cutting performance can perform acrylic cutting with a thickness of 30mm. Because the laser head of this model is specially designed, it shows a bright clean surface without ripples after the acrylic cutting of thick plates.

. Optical fiber laser metal cutting performance Stainless steel can be perfectly cut to 3mm without post-processing. For carbon steel, it can also be cut to a degree of 6~8mm. It is the same grade for professional cutting applications.

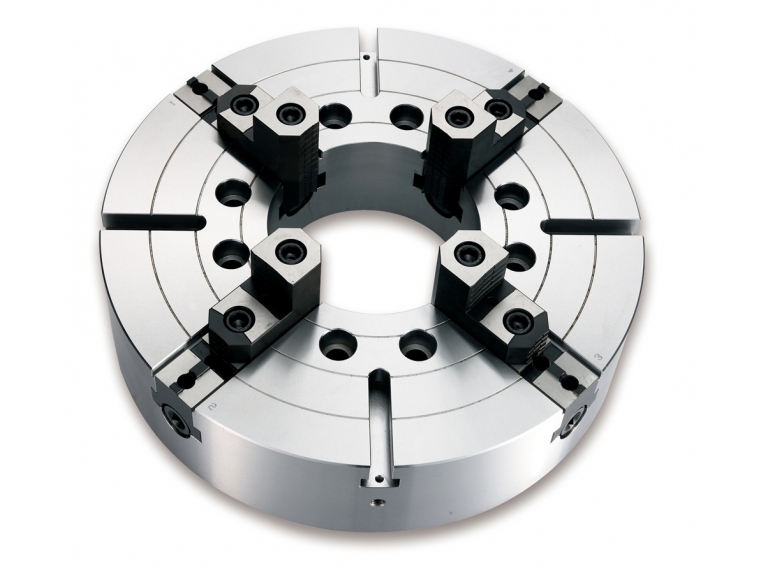

YANMECH Industrial Co., Ltd.

Product Description :

【A Series:】

1. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

【D Series:】

1. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

2. Adapter Plates can be selected.

3. The base jaw is lower than the body surface and can be used for multipurpose.

4. Alternative spindle adaptors:

ASA or DIN adaptors can be supplied as requested.