Theme

Digital Transformation

Green Transformation

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Tungsten Carbide Blade Tool Processing

1. Excellent grinding ability, significantly reducing spindle load, save processing time and cost.

2. Tough texture and wear resistance characteristics to achieve the maintenance of tool dimensional accuracy.

* Processing Material | Tungsten Carbide

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

Product Description :

TECAPET PET polyester from Ensinger is specially formulated to provide improved toughness, and enhanced machinability. This PET polyester also offers excellent sliding and wear properties, and a low coefficent of friction. TECAPET's superior chemical resistance, non staining characteristics, and distinct lack of centerline porosity, makes it a desirable material for a variety of applications especially in the food industry that might involve solvents, cleaning chemicals, or direct food contact.

WELE MECHATRONIC CO., LTD.

Product Description :

1.高剛性高穩定性結構

A. 底座:機器底座採用整體式鑄件,有效確保機器剛性。Z底座採4線軌設計,全行程範圍內直接落地支持,有絕佳的剛性及穩定性,確保整體長期幾何精度。

B. 滑座:滑座採用整體式鑄件,支撐於Z底座上,4線軌設計增加滑座負載剛性。

C. 立柱:立柱採用整體式鑄件,有效確保機器剛性;且固定不移動,大大減少主軸移動行程中所帶來的幾何精度誤差影響。

2. XYZ三軸及W軸導軌均採用先進的超重負荷型「滾柱」線性導軌,大幅度提高導軌「剛性」和「重切削能力」,也繼續保有「低摩擦力、低磨耗、低遲滯現象、低失位量、高速度、高精度、高動態特性、高壽命、不需調整」等線性導軌的優良特性。

3.XYZW四軸的均有過負載保護,如因誤操作造成撞機,可有效降低對機器的損傷。

4.雙編碼器回饋裝置(配置於XYZ三個進給軸),B軸採用(圓光栅-角度編碼器) 廠牌:發格Fagor。

5.主軸箱等關鍵零件係利用「大型臥式搪孔機」及「大型高精度三次元量測儀(三座標量床)」確實達成應有的加工精度,確保優良的組裝基礎。

6.鞍頭:110主軸系統配備搪孔軸直徑110mm,搪孔軸行程W=500mm、3500 rpm(兩檔齒輪箱)。搪孔軸為氮化處理高硬度合金鋼件,前段支持使用傳統的硬化襯套外,後段附加線性導軌的加強支持,借助滾動低磨耗的特性,增長搪孔軸的精度壽命。

7.主軸前軸承採用直徑150mm的高精度主軸軸承,加上改良設計的軸承配置及潤滑設計,有效的提高主軸剛性和壽命。

8.主軸鬆刀採浮動式抓鬆刀裝置,鬆刀時不會施力於主軸軸承上,可長保主軸最佳精度;另,新式鬆刀缸配置設計,可使主軸於任一行程(W軸)位置換刀。

9.特殊設計的自動潤滑系統;潤滑油與切削液分開, 單獨收集可確保切削液的穩定性及工作環境的清潔。

10.刀庫採立柱側背式設計;刀庫與立柱接合,不同於落地型式,立柱固定不移動,刀庫與鞍頭配置可達成左右平衡架構,提高W軸動態穩定特性。

11.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的幾何精度,確保機器應有的精度和壽命。

12.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

13.電氣箱採全密閉式循環熱交換系統,內部配線均參考德國工業安全標準,電源部份與訊號線區隔,以增加機器使用上的安全。

14.搭配高規格的Fanuc 0i MF Plus數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、1280米記憶容量、Ethernet網路接口、Flash記憶卡插口、Manual Guide i圖形對話式編程、剛性攻牙、手動剛性攻牙、AI contour control II等多項高規格功能,能經濟有效的滿足各種使用需求。

15.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

16.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

17.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"ECHAINTOOL is a well-known leading brand in Taiwan. It is the leading manufacturer of professional cutting tools and cooperates with the world's leading brands of cutting tools. It has multiple cutting tool products and sufficient inventory to meet the different needs of customers. The quality products are all made in Taiwan, and have won the ""Taiwan Excellence Award"" and ""Excellent Design Award"" and passed the IS0 9001 certification, which is directly recognized by many customers from the world of aerospace, automotive and mold companies.

Adhere to the promotion of our own brand ""ECHAIN"", mainly develop and manufacture all kinds of discarded cutting tools (carbide end mills, inner/outer boring tool holder, threading tool, various milling cutters, drilling tool, hole boring cutter, rapid drills, etc.) and related components are widely used in CNC lathes and milling machines for various precision machines.

The carbide end mills developed by the ECHAIN team are all produced by the German WALTER five-axis machine to obtain the best quality and effectively meet the needs of the industry. "

FUTURE LIFE TECHNOLOGY CO., LTD.

Product Description :

iHDW系列為新一代智慧型手輪適用於大型或高階機種,螢幕上可顯示座標值及功能狀態,方便操作人員使用。

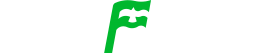

LNC TECHNOLOGY CO., LTD.

Product Description :

‧Low profile, high performance, easy installation, high applicability

‧High sensitivity, high precision

‧measurement:±16G, extremely low signal /noise ratio

‧XYZ three-axis vibration detection

‧Measuring frequency 3.32kHz(max.)

‧EtherCAT protocol

‧Water and oil proof, great anti-interference ability

‧Support time domain graph, frequency domain graph, abnormal vibration section marking of program function

‧Support smart function development: Broken tool detection, abnormal vibration detection, spindle protection, tool wear, adjustment assistance, equipment health inspection, etc.

INNOSERV FA INC. TAIWAN BRANCH (BVI)

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

KING NICE TECH.CO., LTD.

Product Description :

To solve the cutting of iron filings,aluminum powder,fine sediment...and other long-time deposition in the CNC water tank troubled.

Take the air pressure drive way, to avoid pubilc security problems.

Widely used in metal cutting, aluminum processing,grinding problems,engineering plastics Patented technology-easy to deal with oily and water-soluble cutting fluid.

patented technology - special dehydration drying method, can clean CNC water tank.

processing liquid, sludge can also be a short time to cleat.

the maximun filter accuracy can to 1 um.

Fulson Industrial Co., Ltd

Product Description :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

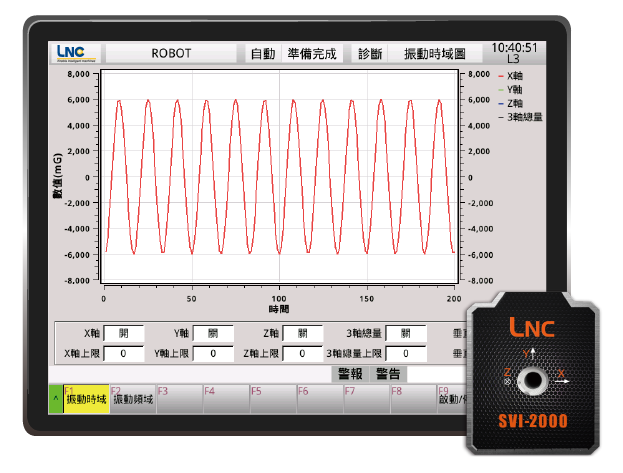

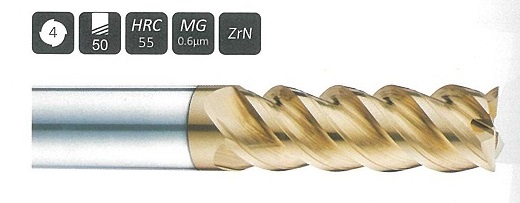

SHARPMAX TOOL INC.

Product Description :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.