EDM Emerges as a Breakthrough in Microfabrication

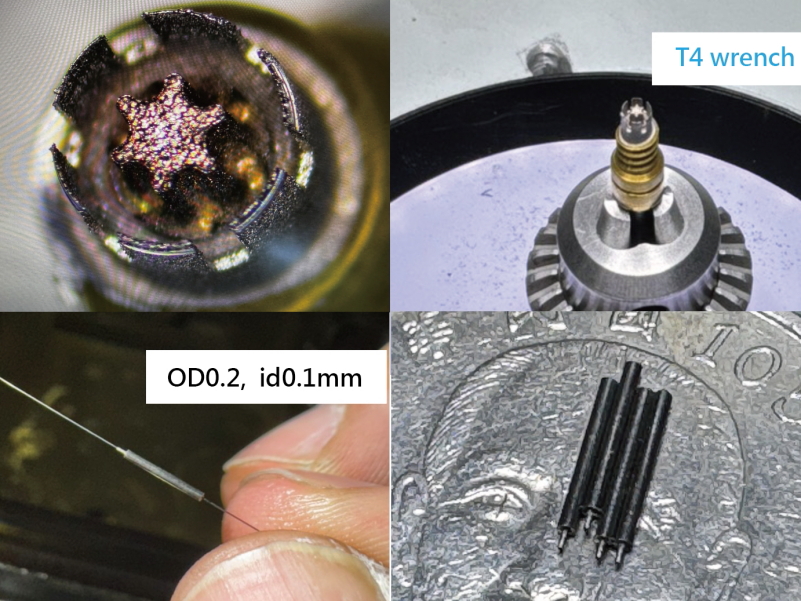

As workpieces continue to shrink in size, conventional cutting tool materials are struggling to keep pace with the demands of advanced micro-machining. In response, Electrical Discharge Machining (EDM) is gaining traction as a transformative solution—offering precision fabrication of ultra-small components without relying on high-end CNC milling systems or costly micro-scale tooling.

Overcoming Tooling Constraints

Unlike traditional subtractive methods, EDM operates through controlled electrical discharges that erode material without physical contact. This enables the creation of structures with extremely high aspect ratios and minute geometries that would otherwise be limited by tool strength, wear, or accessibility. Researchers and manufacturers are increasingly turning to EDM to bypass the limitations of mechanical tooling in micro-scale production.

Implications for Industry

- EDM facilitates the fabrication of components in hard-to-machine materials and complex geometries, especially in fields like MEMS, semiconductor packaging, and precision mold making.

- It reduces dependency on ultra-precise CNC systems and specialized micro-tools, lowering both capital and operational costs.

- The technique supports scalable production of micro-parts with consistent quality and repeatability.

Looking Ahead

As industries push toward miniaturization and ultra-precision, EDM is redefining the boundaries of what’s possible in microfabrication. Its non-contact nature and high controllability position it as a key enabler of next-generation manufacturing.

As workpieces continue to shrink in size, conventional cutting tool materials are struggling to keep pace with the demands of advanced micro-machining. In response, Electrical Discharge Machining (EDM) is gaining traction as a transformative solution—offering precision fabrication of ultra-small components without relying on high-end CNC milling systems or costly micro-scale tooling.

Overcoming Tooling Constraints

Unlike traditional subtractive methods, EDM operates through controlled electrical discharges that erode material without physical contact. This enables the creation of structures with extremely high aspect ratios and minute geometries that would otherwise be limited by tool strength, wear, or accessibility. Researchers and manufacturers are increasingly turning to EDM to bypass the limitations of mechanical tooling in micro-scale production.

Implications for Industry

- EDM facilitates the fabrication of components in hard-to-machine materials and complex geometries, especially in fields like MEMS, semiconductor packaging, and precision mold making.

- It reduces dependency on ultra-precise CNC systems and specialized micro-tools, lowering both capital and operational costs.

- The technique supports scalable production of micro-parts with consistent quality and repeatability.

Looking Ahead

As industries push toward miniaturization and ultra-precision, EDM is redefining the boundaries of what’s possible in microfabrication. Its non-contact nature and high controllability position it as a key enabler of next-generation manufacturing.

CASTEK MECHATRON IND. CO., LTD.

Brand Name:

CASTEK

Booth Number :

H0927

Contact Information :

- www.castek-edmdrill.com/

- +886-4-8651288

- +886-4-8656538

- No. 116, Chung Shan Rd.,, Changhua County 516018, Taiwan