展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

R PLUS TECHNOLOGY CO., LTD

製品の説明 :

1. Automatic detection cutting processing work. Prevent cutting process failure or missing.

2.After cutting the part surface smooth with better quality.Good quailty.High stability.

3.Best cutting state feedbacck signal function. Can be connected to the manipulator or robots. The installation is more convenient.Widely versatility.

4.Automatic testing possesses function. While system upfrades to industrial 4.0, ours products still can be used. Reducing the risk of investment and waste

HONG JI PRECISION MACHINERY LTD.

製品の説明 :

Drilling capacity is from Ø5mm to Ø40mm and the max. drilling length is 3000mm

The machine is suitable for drilling accessories of petroleum system, tube holes of heat-exchangers, long mechanical sleeves and long aerospace parts.

Slideways of all axis are harden box ways with heat-treatment to HRC52, this design has good damping to absorb vibration as drilling big and long holes.

The worktable is loaded on the harden box slideways with width 200mm. The max. loading weight on the worktable is 20tons.

The width of column is 2 meters with two sub-columns to provide the excellent support to Y-axis as moving up and down. Total weight of the machine is about 38tons.

KAO FONG MACHINERY CO., LTD.

製品の説明 :

This series is the fix-column bridge type machining center which adopts fixed crossbeam and column, but moveable table . X and Y axes use the roller type linear guide way, and Z axis offers box way or linear guide way according to customer’s needs. In addition, it can be equipped with various types of manual attaching head (90 degrees milling head, universal head,extension head, multi-directional head etc.). Applicable to all kinds of parts processing, mold mold processing, aluminum parts and aerospace transportation parts processing industry etc.

JIN LI CHENG CUTTING TOOL CO., LTD.

製品の説明 :

向全球使用金利成刀具的加工航太客戶,深深感謝。

JLC為全球客戶開發了多款加工鈦與WASPALOY及鎳基材料的經典刀款,獲得客戶的持續讚賞與肯定,我們也因為航太客戶的持續互動,一直追求創新與進步。

航空零部件不僅採用了很多新結構、新技術和新材料,零件也越來越講求精密與材料合適性。為了讓客戶在航太的加工上,有更多元的因應方式,我們正式推出新設計的航太特殊材料用刀– AP系列。

整體子彈流動力學的設計理念,與一貫的優質歐系棒材,再搭配更勝一般鈦矽的複合及類鑽鍍層,經過廠內多次的實驗,AP航太系列刀具,絕對讓您面對航太材料加工上游刃有餘。

歡迎全球客戶指教,金利成再次感謝您的支持。

Lanza International Co., Ltd.

製品の説明 :

Global Supply Chain Reshaping|Taiwan’s Hardware Industry Moves Toward Intelligence and Sustainability

In an era of global supply chain restructuring and accelerated smart manufacturing transformation, Taiwan has emerged as a vital hub in the global hardware industry—powered by its outstanding precision manufacturing capabilities, flexible supply chain system, and innovative R&D strength.

The 2025 Taiwan International Tools & Hardware Expo x International Hardware Expo Taiwan (TiTE x IHT) will be grandly held from October 21 to 23 at the newly completed Taichung International Convention and Exhibition Center.

With "TEAM TAIWAN" as its core theme, this year’s edition brings together Taiwan’s industrial cluster strengths and global sourcing demands to create a one-stop sourcing platform for international buyers, reinforcing Taiwan’s role as a central force in the global hardware supply chain.

MONGTEC PRECISION INC.

製品の説明 :

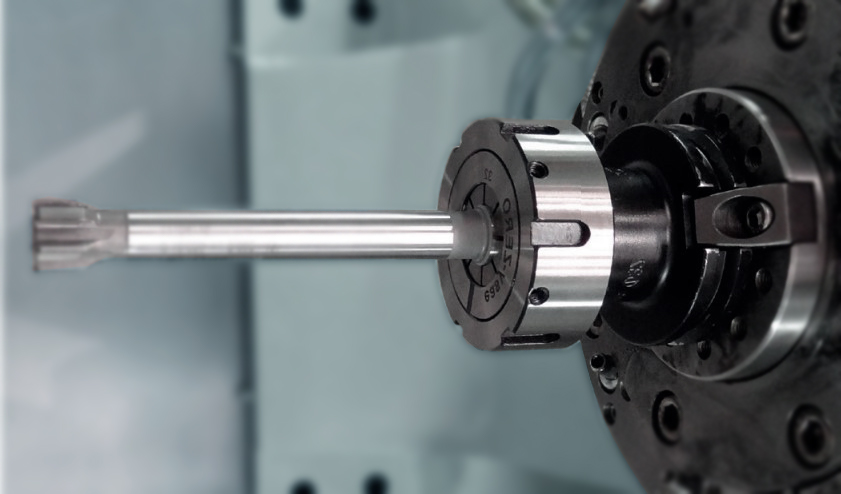

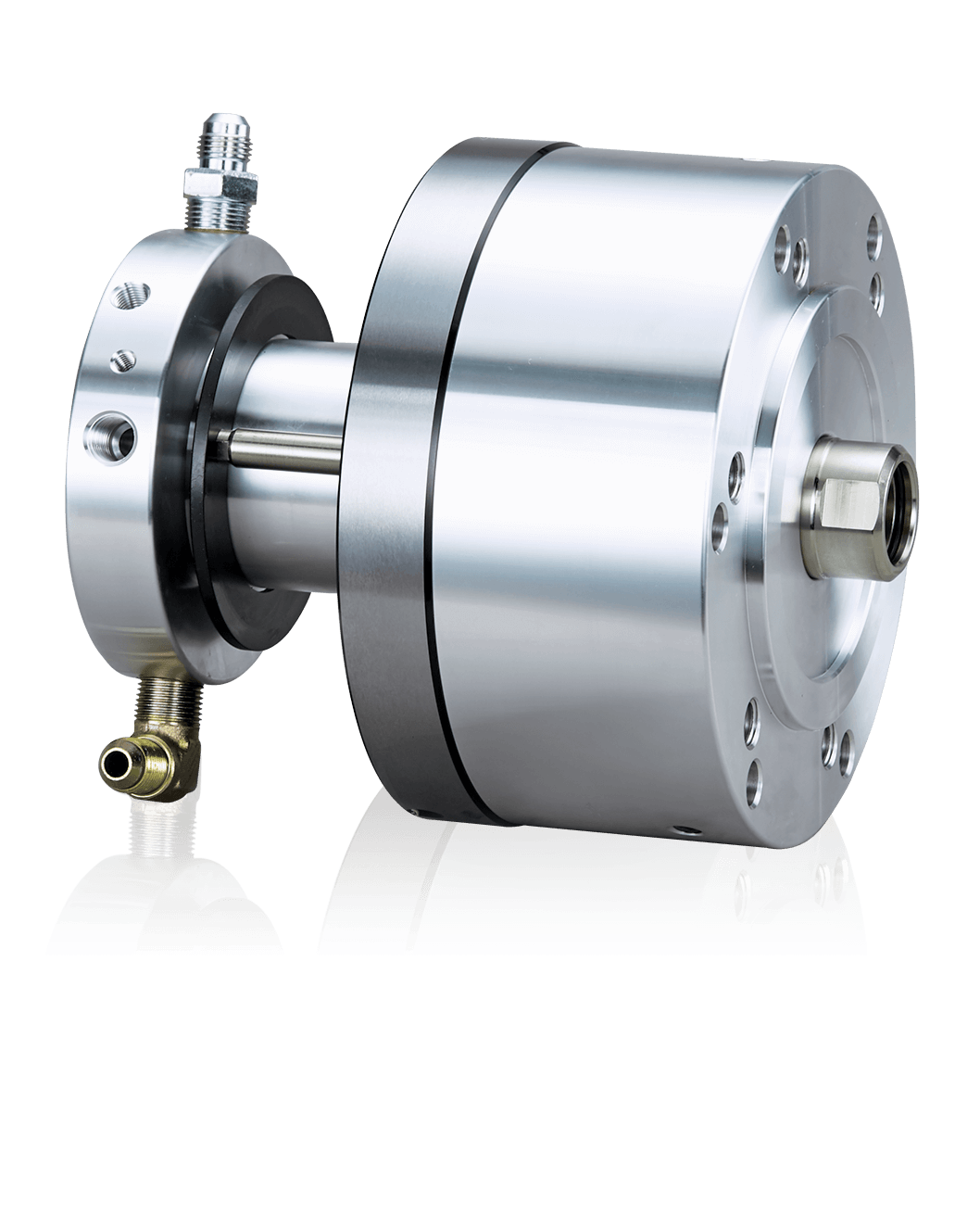

Product Features

◎ Correction of runout errors and misalignment

◎ For metallic sealed and normal collets as per DIN 6499 / ISO 15488

Product Advantages

◎ Easy to set

◎ Maximum process capability due to correction of runout

◎ Extended tool life due to perfect runout

◎ Highest quality of bores due to correction of runout

QUASER MACHINE TOOLS, INC.

製品の説明 :

MF700’s design concept is to strengthen Column-moving C frame structure, and separate linear & rotary axes, optimize it with FEMA analyze, the advantages are high rigidity in structure, high precision in machining, and operator friendly. To separate linear & rotary axes is to minimize the following errors and ensure machining accuracy, on top of that, the transmission mechanism/components is away from working area which can reduced parts failure from pollution of coolant and chips.

The linear axes has a cross-frame design, the wide-span column and large-size linear way blocks provides excellent stability during high-speed cutting. Rotary table is intergraded with bridge type column, this compact design can bring us smaller footprint and maximize working envelope.

Rotary table with tailstock support can increase the load capacity which is capable up to 500kg, maximum swing for workpiece is 700mm and height is up to 500mm.

The standard worm gear/wheel and encircling brake design provide high rigidity and lock-force. For different application like high speed demand in aerospace, it can be upgraded with dual Direct Drive Motor.

Operator friendly design with 2 wide open doors are not only easier for operator but also easier for automation upgrade. More thoughtful is we offer three different types of top guards for different work environment, telescope type, solid top cover and open top.

New base design allow chips fall onto conveyor directly, reduce 50% your chip cleaning time.