展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JAR HON MACHINERY CO., LTD.

製品の説明 :

1.The machine can be attached double spindle head and work efficiency can be more increased.

2.Both cutting TAP and forming TAP are suitable.

3.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

4.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

5.It can install additional hopper to increase automatic working.

6.It can install additional sheet metal cover to gain more safety and reduce noise.

7.Pre-work parts auto-checking and machine auto-stop if abnormal.

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

Our portfolio covers form knurling tools, cut knurling tools, knurling wheels and marking tools in market-leading technology and quality. Our innovative power is reflected in our modern tool systems and in the continuous optimization of our production processes. The intensive dialogue with tool users from all over the world helps us to permanently improve our product concept. Modular tool systems provide the decisive extra benefit with regard to flexibility, versatility and speed.

The longstanding experience in our core competence, the profiling of knurling wheels, enables us to offer a wide standard range of high-precision knurling tools, knurling wheels and marking tools and is at the same time the perfect basis for designing, developing and producing first-class individual tool systems which are exactly customized to any special requirement.

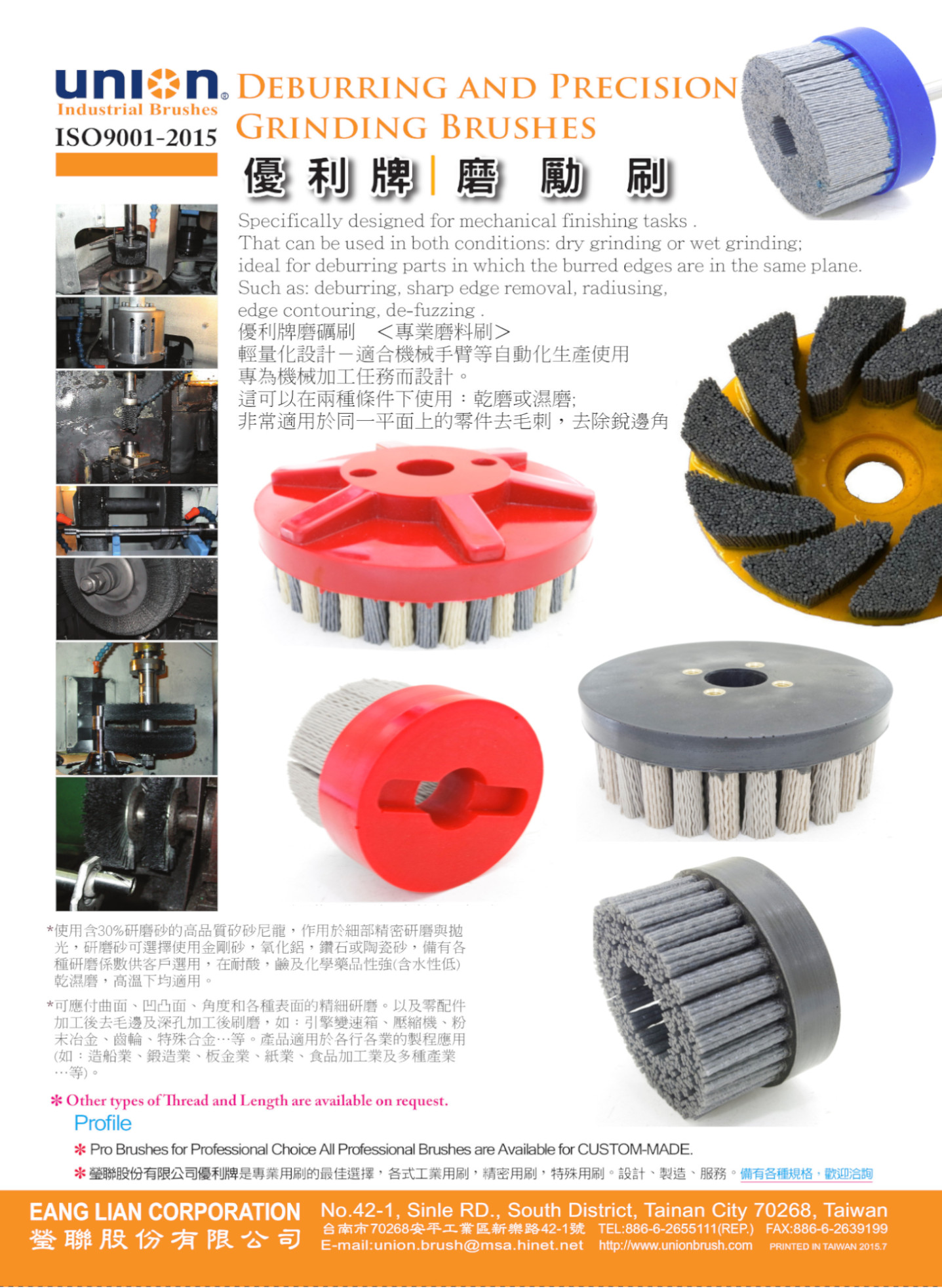

EANG LIAN CORPORATION

製品の説明 :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

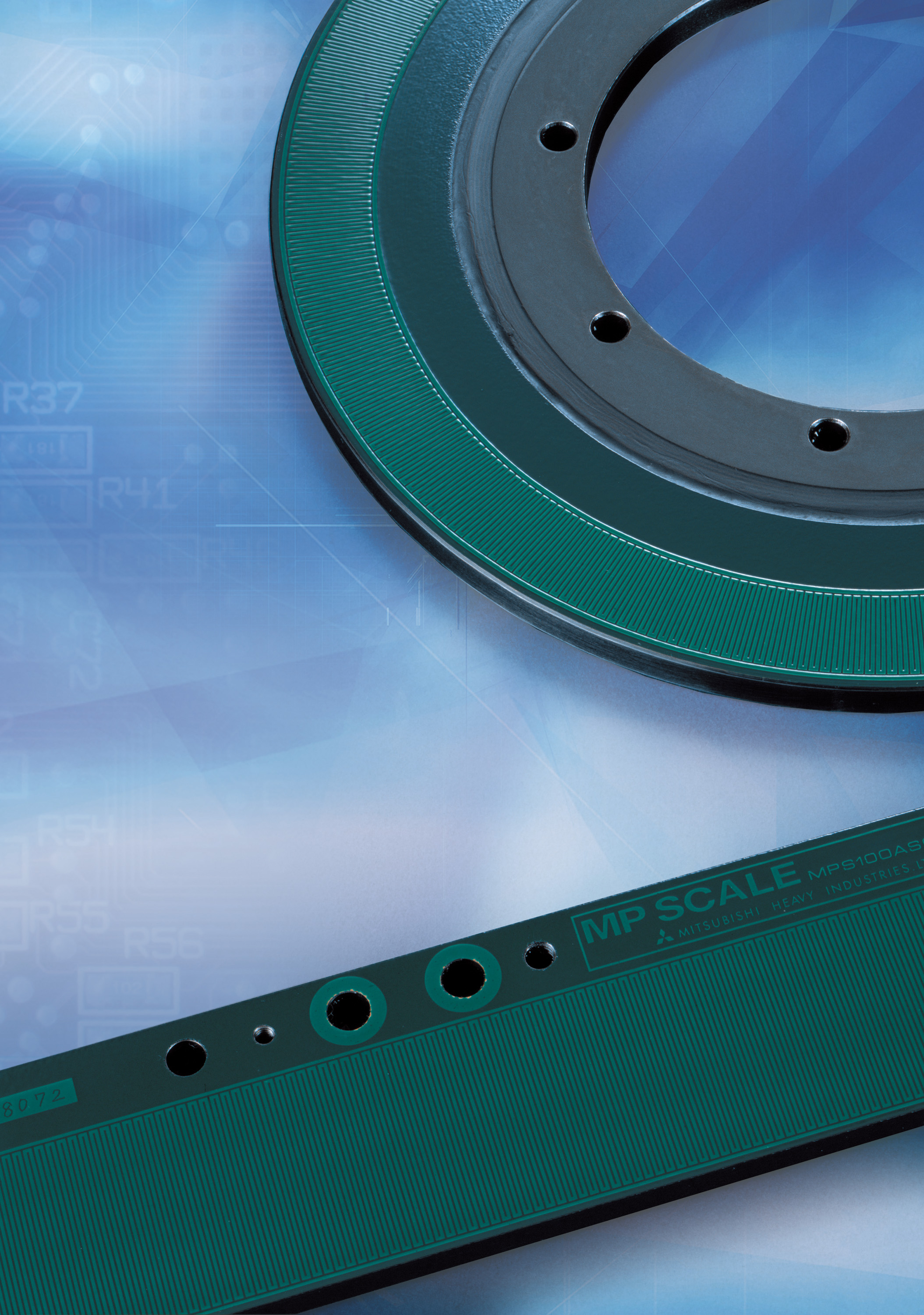

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

Linear encoders are indispensable for machines with high demands regarding positioning accuracy and machining speed. Linear encoders directly and immediately measure the actual position of the feed axis. This makes it possible to eliminate a number of potential error sources: Positioning error due to thermal behavior of the recirculating ball screw

, Reversal error, errors due to deformation of the drive mechanics by machining forces, kinematic errors through pitch error in the recirculating ball screw.

YOKE INDUSTRIAL CORP

製品の説明 :

1. Size from M8 to M90 to fulfill your demand

(M8 ※ 0.3t _ M90 ※ 40t)

2. Design Factor 4:1, Working load limit could be up to 40 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. Suitable for all loads which swivel and tilt especially for heavy duty, material handling, mold & die industries.

5. Ball bearing inside is easier for flipping working piece and rotation.

6. Light weight, High Performance, easily for using

7. Deliver with test certification to guarantee your safety

DEEP JET INDUSTRY CO., LTD.

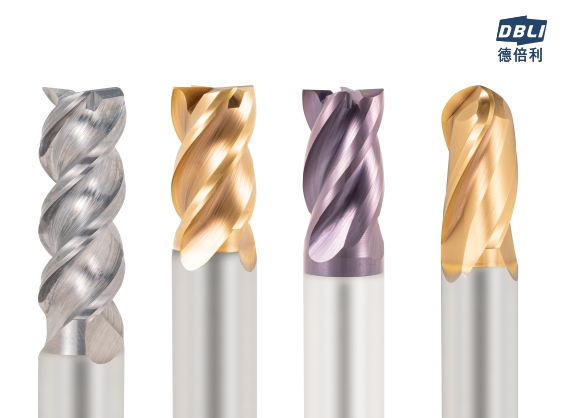

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

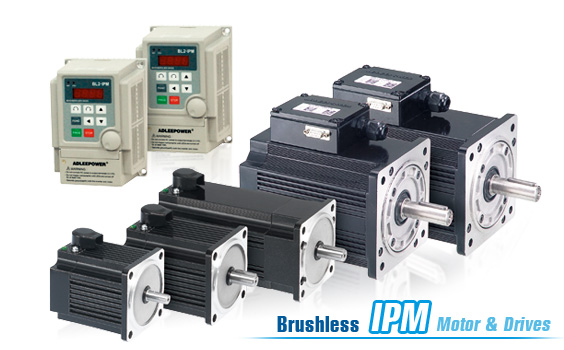

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Product applications:

Internal & External grinder 、Conveying equipment、Coffee roasting equipment、Centrifugal equipment、Polishing equipment、Emulsifying machine、Glass edge grinder、Auto polisher grinder, etc.

Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.