展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

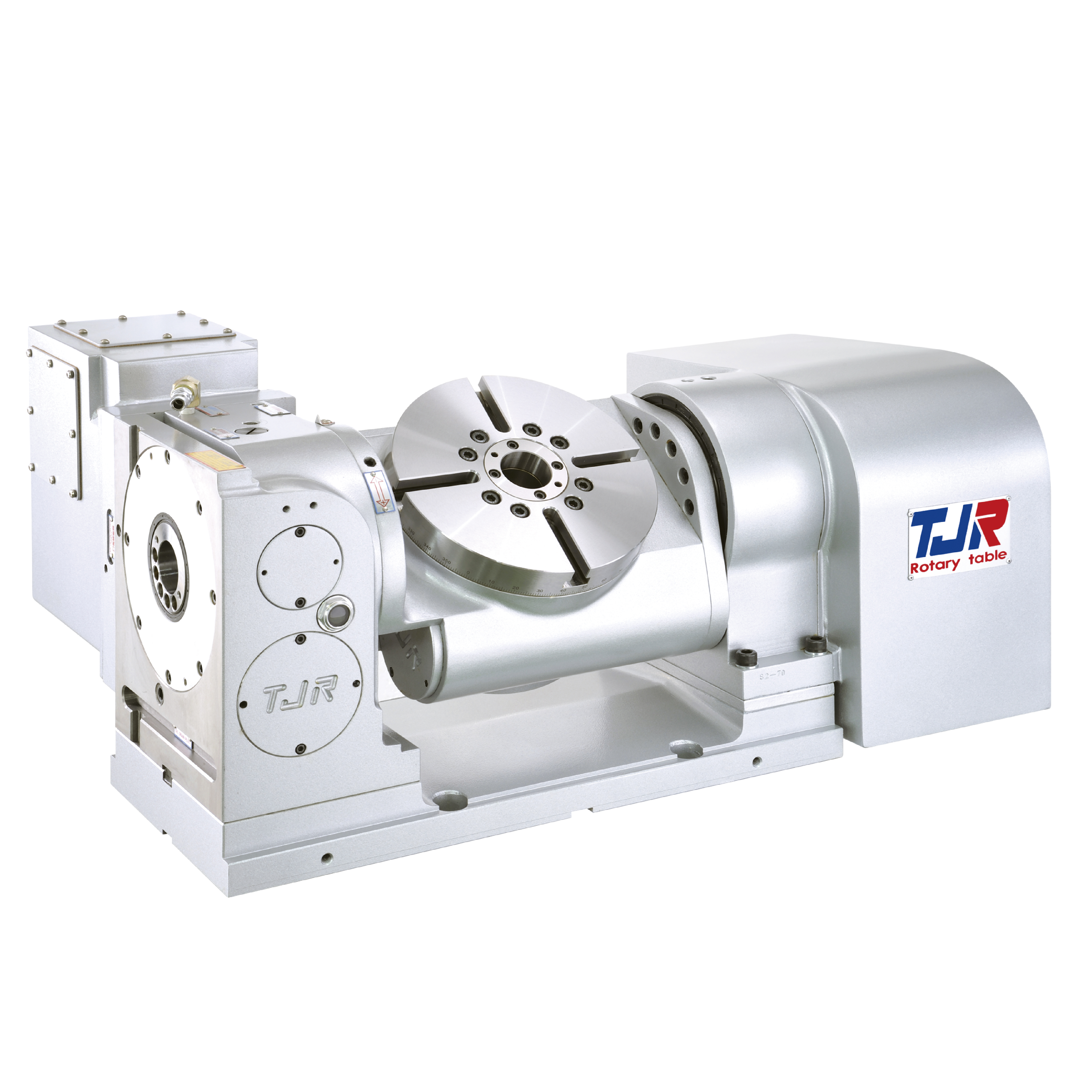

TJR PRECISION TECHNOLOGY CO., LTD.

製品の説明 :

① Both the tilting axis and rotary axis use large-diameter radial & axial bearings.

② Because the tilting axis normally needs to bear heary load, Japanese-made worm and worm gear are employed to improve wear resistance and precision of the tilting axis.

(Its wear life is 2.6 times longer than aluminum bronze PBC3.)

③ Anti-wear alloy steel worm gear is optional.

④ A hydraulic brake for the tilting axis is optional.

PROTH INDUSTRIAL CO., LTD.

製品の説明 :

1.A : Auto-cross H : Hydraulic longitudinal R : Rapid up/down.

2.Overall architecture (horizontal module) : Overall structural design optimization /lightweight/stiffness strengthen.

3.Built-in spindle (15HP) with 20 inches grinding wheel.

4.Workpiece shape : flat grinding/step/plunge grinding.

5.Machine drive : Cross and vertical liner guide way, longitudinal double V guide way.

MANFORD MACHINERY CO., LTD.

製品の説明 :

CNC Horizontal Lathe With Sub-spindle/Power Turret/Y axis

●Adopts high-rigidity bed and guideway design to increase stability during processes.

●Equipped with two spindles and power turret with Y-axis movement function, which can handle different complex machining including milling.

●Adopts BMT-55 interface to support a variety of processing tools.

●High-speed performances of the first spindle motor 11/15 kW and the sub-spindle motor 7.5/11kW are suitable for heavy-duty cutting.

●Optional robotic auto loading system is suitable for mass production.

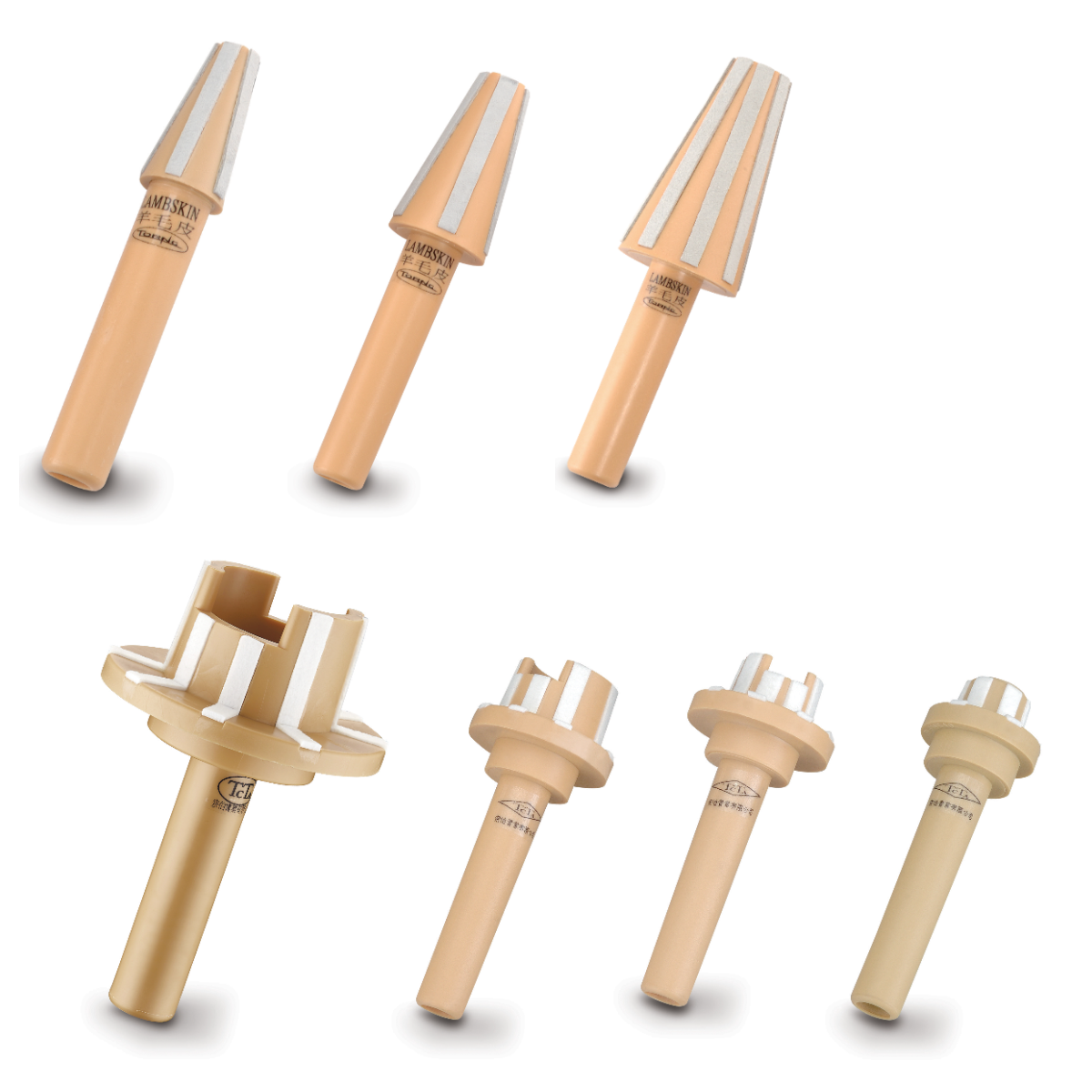

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1.Special cutting-edge design with low resistance to reach better chip-off from the groove. This shows the tool's stability in high speed machining.

2.The special coating enhances the anti-oxidation and wear resistance to increase high speed performance.

◆Carbide Drills With Internal Coolant Holes:

Internal coolant holes can highly increase the performance of cooling and chip removal rate.

◆Carbide Flat Drills:

Good for curve and inclined surface machinning.

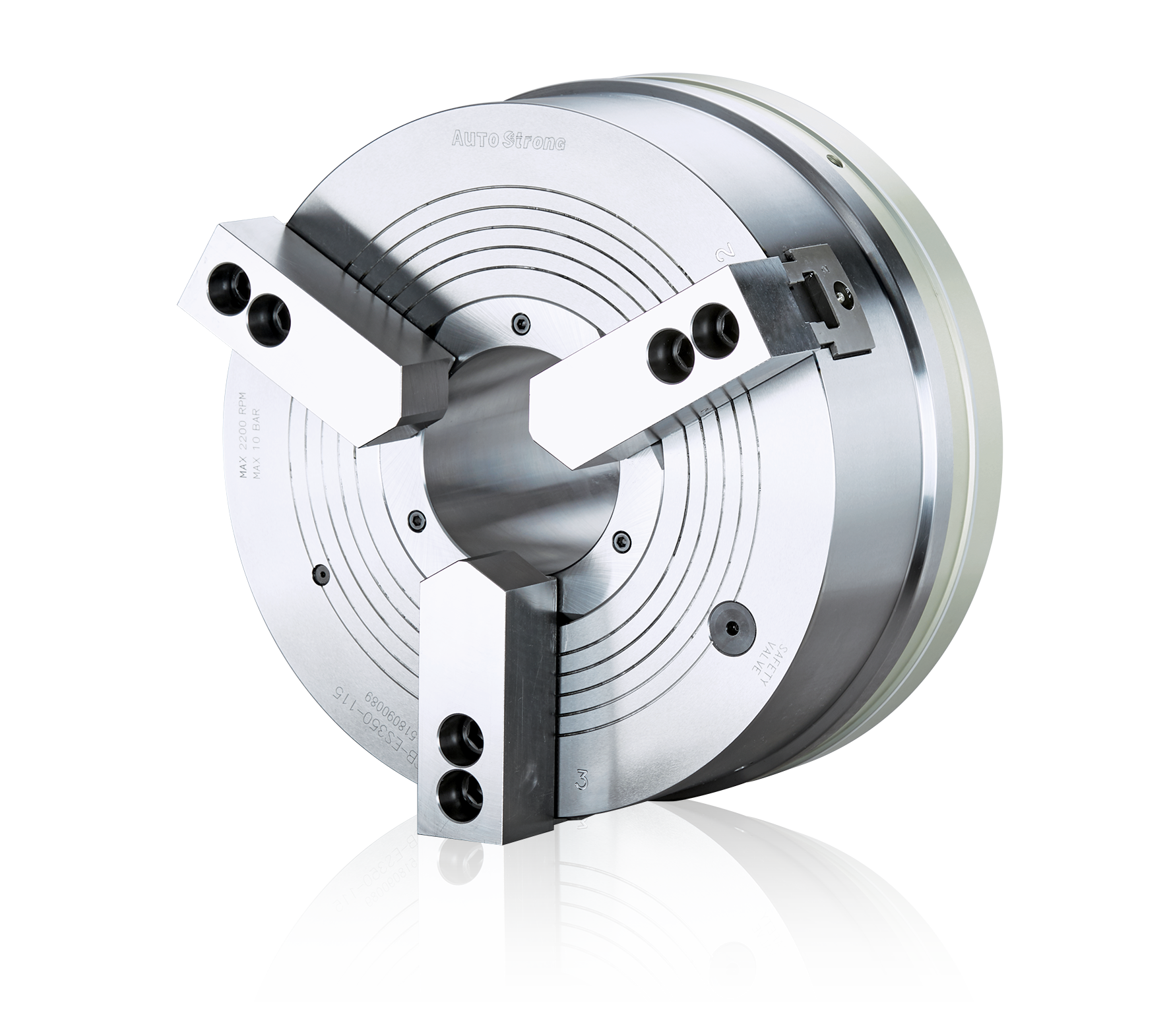

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.