展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

LNS TAIWAN CO., LTD.

製品の説明 :

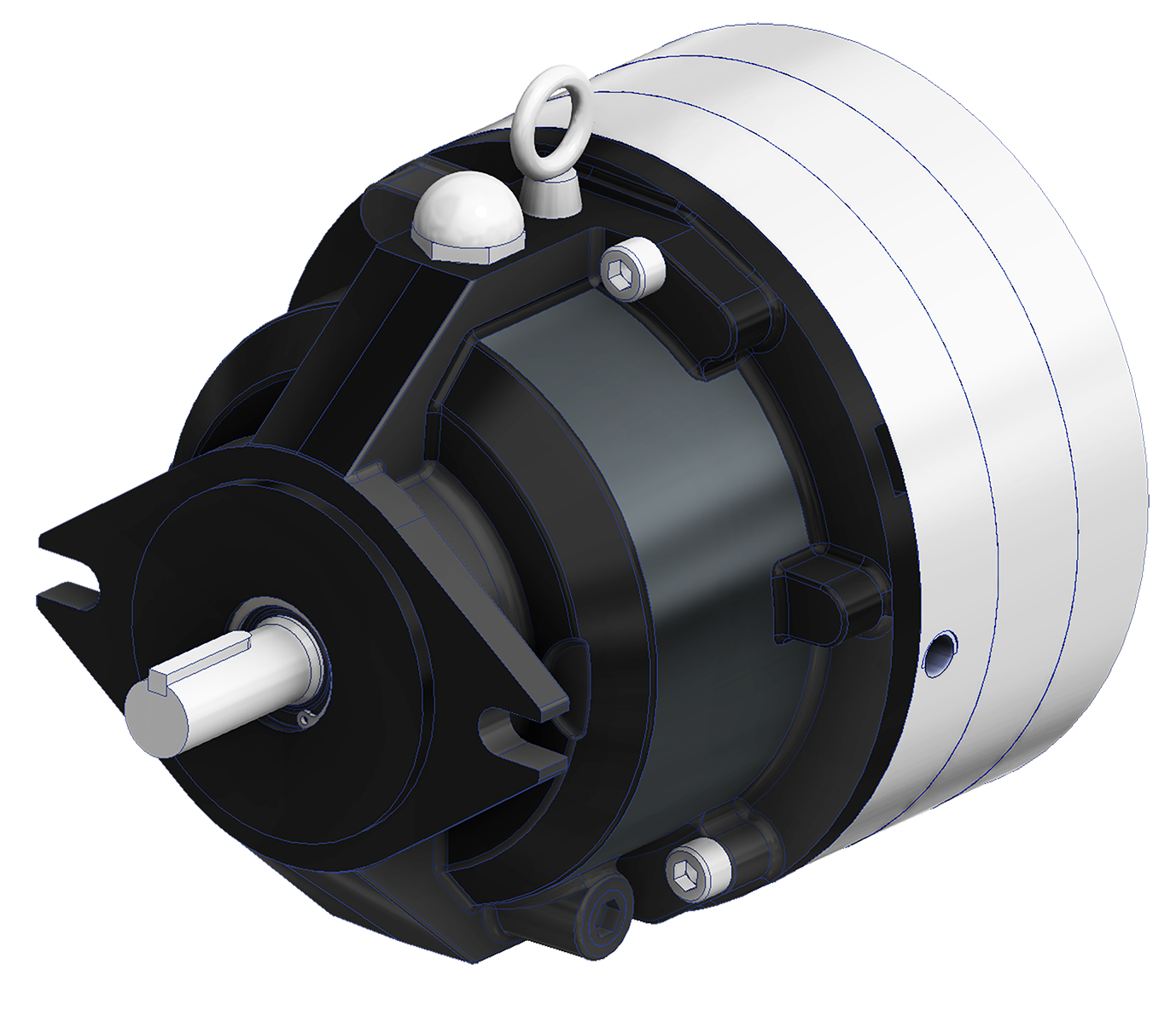

The SL65 S is an entry-level alternative for spindle length bar stock feeding. The SL65 S is designed for simple applications, especially for standard production parts, and for medium and large production runs.

●The SL65 S permits easy adjustment of the diameter.

●The operator-friendly remote control ensures the interaction between the bar feeder and the lathe.

●The SL65 S retraction system facilitates access to the lathe without compromising the precision of the alignment.

WEXTEN PRECISE INDUSTRIES CO., LTD.

製品の説明 :

■ The unit is lightweight, easy to install and noiseless.

■ Unlike traditional air conditioners, the system utilizes oil/water for heat exchange, instead of piping refrigerant gas directly to the cooling coils.

■ Amazing performance even in high environmental temperatures.

■ Achieving energy savings and carbon reduction by applying secondary circulation with P.C.W. or the oil/water coolers.

■ No compressor, no need for refrigerants, so no concerns about Global Warming Potential (GWP) values.

SIEMENS LTD., TAICHUNG BRANCH OFFICE

製品の説明 :

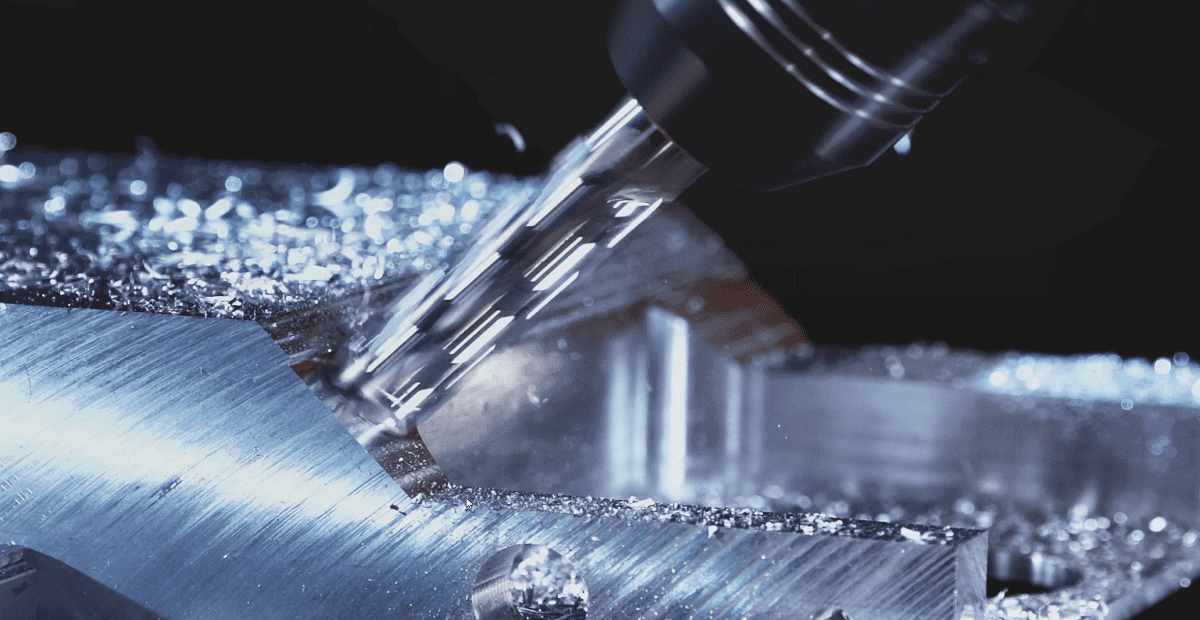

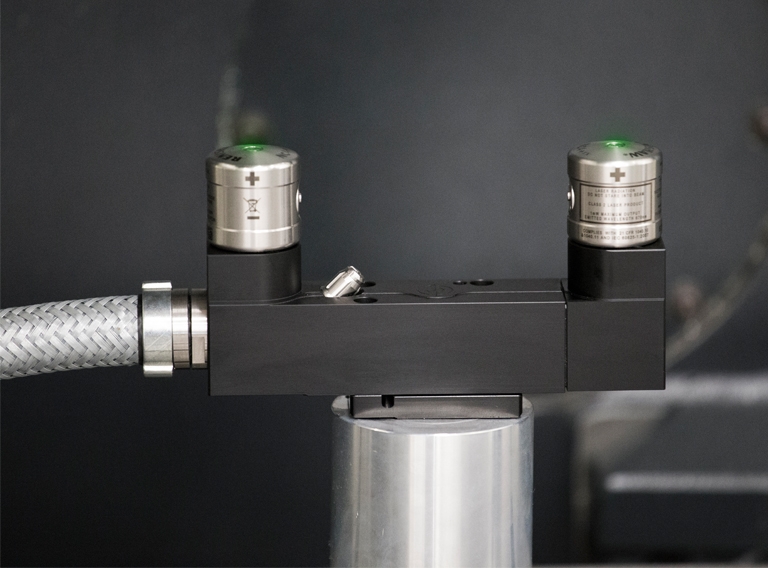

Optimizing the machining process using real-time data

Machine tool users incur unnecessary costs as a result of tool breakages, unexpected surface quality anomalies, cutting tools being replaced too early, and longer non-productive machining times. Do you know how to avoid these pitfalls and save money by leveraging your real-time cutting data?

Fulson Industrial Co., Ltd

製品の説明 :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

Mighty Spraying Technology Co., Ltd.

製品の説明 :

1. Built-in patented circulation pump, it makes a low

working temperature, and extending the service life

of pump.

2. Special design, it can prevent the pump from the

damage of opertion without liquid.

3. High pressure, high efficiency diaphragm pump,

which can be used for high viscosity liquids (160

cSt).

4. Minimum 300 rpm , 1200rpm.

This character make MPD pump can be combined

with electric servo motor as energy saving system.

5. Maximum working pressure: 100 bar.

6. MPD pump can be use in pure water systems. It can

reduce the using of coolant in cutting system,

which will be friendly of environment.

7. Tolerate higher particles, as a non-contact pump,

MPD pump can take maximum particles is 500

micron.

MATRIX PRECISION CO., LTD.

製品の説明 :

GVP-8040 applies the FANUC controller and high speed grinding spindle; through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters.

The machining workpieces include involute gear, large-module hobs and cycloidal gears; the high-efficiency and high precision expressed from the products are equivalent to worldwide-top brand’s ones; GVP-8040 is your best choice.