Theme

Digital Transformation

Green Transformation

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

Lotus Business Information Co., Ltd.

Product Description :

SEISANZAI MARKETING Magazine is a Japanese monthly journal launched in 1964. We have provided highly valuable information on the industry in Japan and abroad, reports on machine tool exhibitions, and the latest industrial statistics for more than half a century.

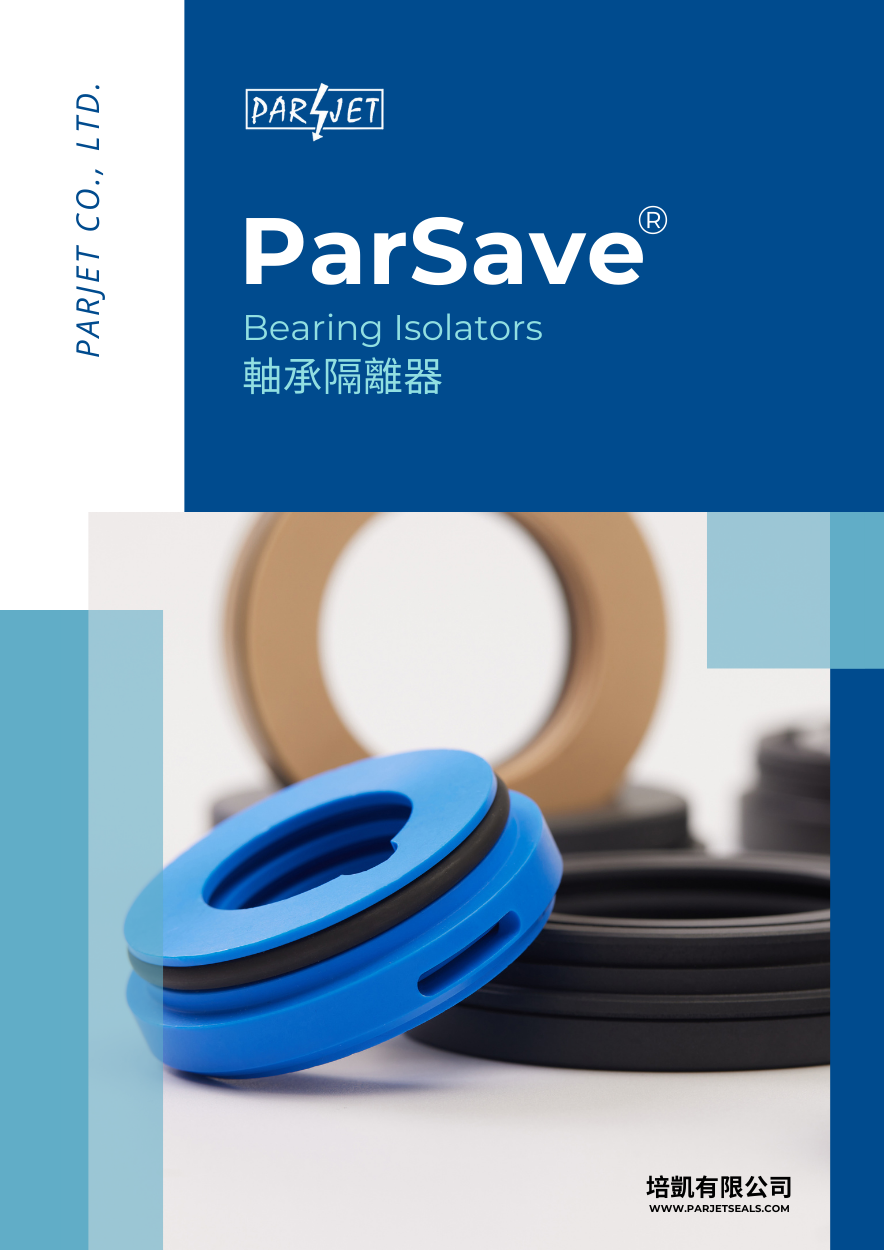

Parjet Co.,Ltd.

Product Description :

ParSave® - Bearing Isolator, is an extension of Parjet PTFE products. It is a sealing device developed to protect the rolling bearings of rotary equipment and can replace traditional lip seals (also known as rubber oil seals). The special configuration of the labyrinth ring combination helps to eliminate common sealing issues. Common issues includes the shaft damages caused by the wear of the rotating shaft from the lip seals and malfunction caused by the intrusion of foreign objects or water vapor. ParSave® can effectively extend the service life of the bearings and rotating shafts. Additionally, due to the unique sealing mechanism, there is no contact between mating surfaces, so there are no potential wear and pollution problems. With the characteristics of the PTFE material such as excellent heat resistance, self lubrication and chemical resistance, ParSave® can operate effectively under harsh environments.

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

Feature of product :

The light spot can be adjusted from 0 to 300mm;

Rust removal gun weight 0.7KG

The system monitors the running status from time to time, monitors and collects the running status of lasers, chillers, and control panels;

Light weight, small size, ergonomic design, comfortable grip;

The safety lock touches the light;

The operation is simple and easy to use, and the requirements for operators are extremely low;

Strong anti-interference;

The fully sealed structure has built-in water and air channels;

Safe and pollution-free, low maintenance cost;

The hand-held laser rust removal and cleaning machine adopts the latest generation of optical fiber laser, which has the advantages of simple operation, small appearance and fast cleaning speed. It has an irreplaceable cleaning process in hardware material rust removal and oil removal. Easy to install, control and automate. Simple to operate, turn on the power and turn on the equipment, you can clean without chemical reagents, media, dust and water, you can manually adjust the focus, clean with curved surfaces, and clean the surface with high cleanliness Advantages, can remove resin, oil, stain, dirt, rust, coating, plating, paint on the surface of the object.

DYNA COMPRESSOR CO., LTD.

Product Description :

Air end compression system

100% imported from Germany. Inorder to ensure the quality ofoperation and stable air flow of the air compressor, we use Germanhigh-precision rotors with stableperformance, excellent quality, and more durablity.

Dyna Compressor With continuous R&D and renovation, our product is advance with times, our goal is to be the most competitive brand,

professional, exquisite, design that with enough flexibility and mobility to meet challenges of the market. Customized is our standard procedure. We grab every possible chance to provide new opportunity and vitality for

industrial reengineering. Under this rapidly changing, competitive era, the

only constant belief of ours is “quality is our strength”.

FUTECH PRECISION CO.,LTD.

Product Description :

Ultra-short, high speed, light weight.

Designed with a detection device, which can be equipped with an inductive proximity switch.

Easy to adjust to ensure the correct operation of the hydraulic cylinder.

Built-in safty self-locking valve and pressure relief valve.

Dual-purpose type, can be installed by the front and rear ends.

The oil pipe must be connected to the oil pressure tank separately to avoid back pressure.

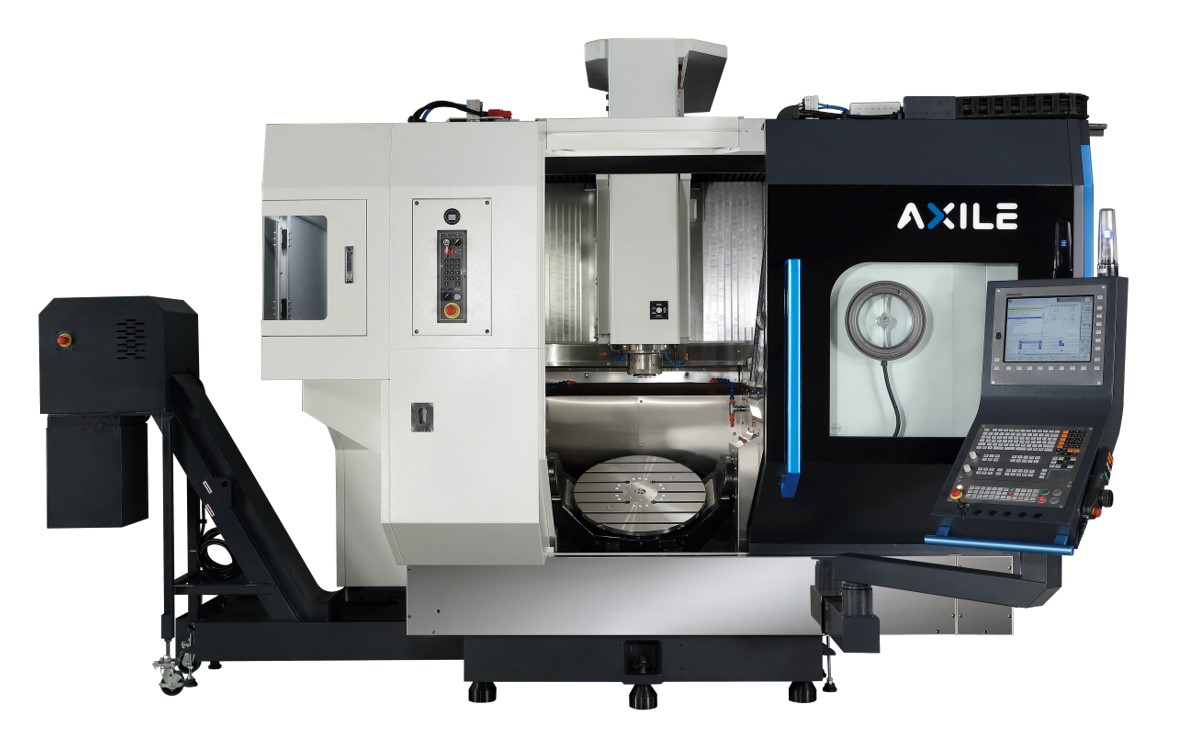

BUFFALO MACHINERY CO., LTD.

Product Description :

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.