Theme

Digital Transformation

Green Transformation

YIH KUAN ENT CO., LTD.

Product Description :

1. IK milling heads can upgrade or replacement your original machine body, milling machine or special machine.

2. Chrome quill with super precision preloaded bearing can bring the high quality cutting benifits for machine and we also offer P4 bearings for your optional.

3. Machining travel can up to 127mm (5").

4. This product offer NT30 or R8 two kind of spindle machine model for you to optional.

5. Offer table 254x1720mm、X.Y.Z travel 851x405x440mm turret milling machine body (whole body) for you to optional.

6. There are 11 models in IK Turret Milling Machine Head Series.

With ultra-precision pre-load bearings, can bring you high-quality cutting benefits, but also provide P4-class bearings for you to choose from

MATRIX PRECISION CO., LTD.

Product Description :

GVP-8040 applies the FANUC controller and high speed grinding spindle, through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The machining workpieces include involute gears, large-module hobs and cycloidal gears, the high-efficiency and high precision expressed from the products are equivalent to worldwide top brand’s ones. GVP-8040 is your best choice.

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

YG started manufacturing mechanical type hobbing machines since 1963. "Hobbing is our everything" is the slogan in YG. From it, we can say that YG has very good experience in hobbing machines design, and manufacturing.

YG uses HERA as a name for their CNC hobbing machines series. They have wide network in Europe, America and Asia with experienced and professional companies sell HERA there. The HERA series hobbing machines are all full CNC control. They have strong and rigid machine frams. YG uses world class one transmission elements with Fanuc and Siemens full package controller and servo units on their HERA series . It makes HERA has good start point and it really does.

In Taiwan, ATMAX is the agent of YG. ATAMX helps YG sell the HERA series. It is successful already that there severl users are using HERA manufacturing their high precision gear parts.

We always welcome new friend joint us.

MATRIX PRECISION CO., LTD.

Product Description :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

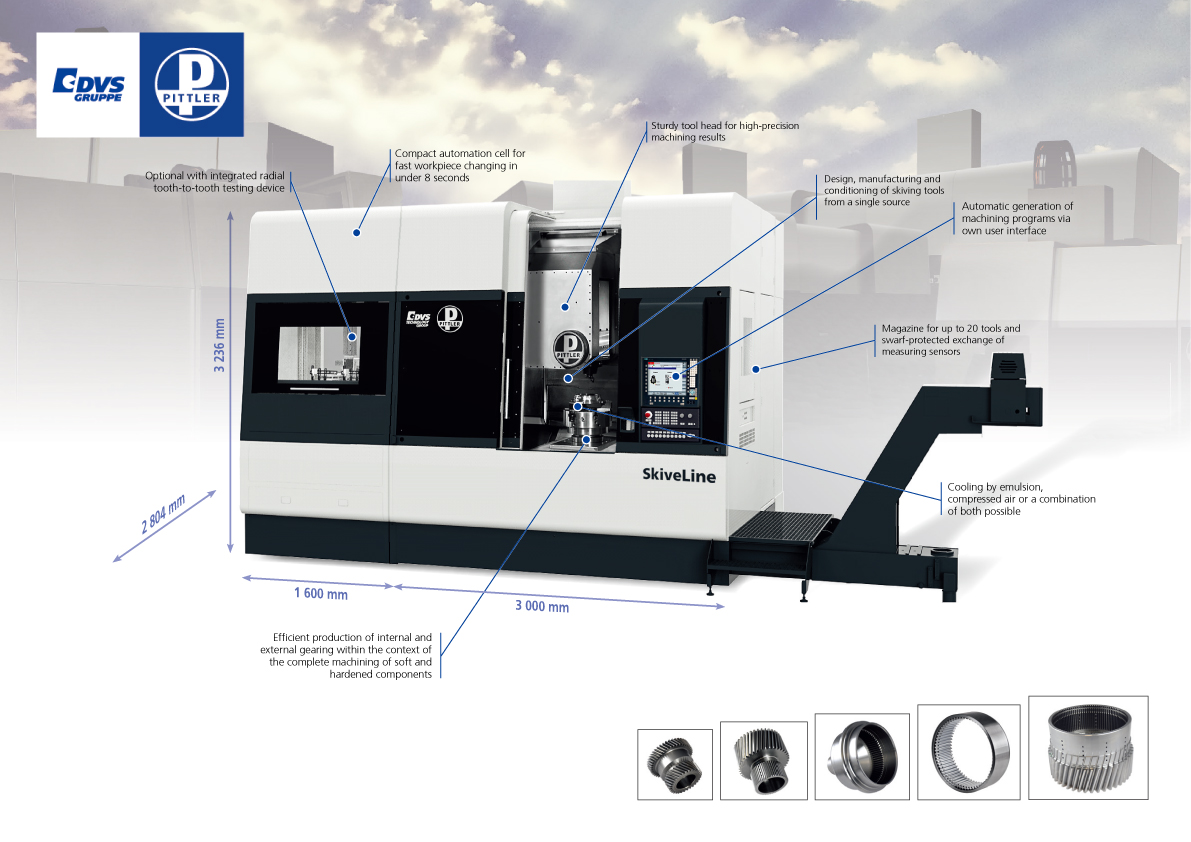

PITTLER SKIVELINE - THE GEAR CUTTING MACHINE THAT CAN DO MORE THAN JUST GEAR CUTTING

Efficient production of internal and external gearings on ring gears, step-pinions, planetary gears or other cylindrical parts with diameter in big range.

Power Skiving or Hard Skiving machine for soft and hardened components.

Sturdy tool head for high-precision machining results.

Complete skiving tool service from one single source – from design of the tool to post-machining.

Automatic generation of gear machining programs via intuitive user interface.

Magazine for up to 20 tools and swarf-protected exchange of measuring sensors.

Compact automation cell for fast workpiece changing in under 8 seconds

Cooling by emulsion, compressed air or a combination of both possible

Optional with integrated radial tooth-to-tooth testing device.

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

YIH KUAN ENT CO., LTD.

Product Description :

1. Semiautomatic processing angle head suitablel in all type of milling heads, can change the processing angle and also bring the powerful and high-quality cutting benefits for machine.

2.This product uses for Japanese gear grinding, so the spindle speed can up to 2000rpm and also can bring the powerful and high-quality cutting benefits for machine.

3. This product offer manual or semiautomatic two type for your optional.

4. This product offer one degree or five degree for your optional.

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.

ATMAX TECHNOLOGY INTERNATIONAL CO., LTD.

Product Description :

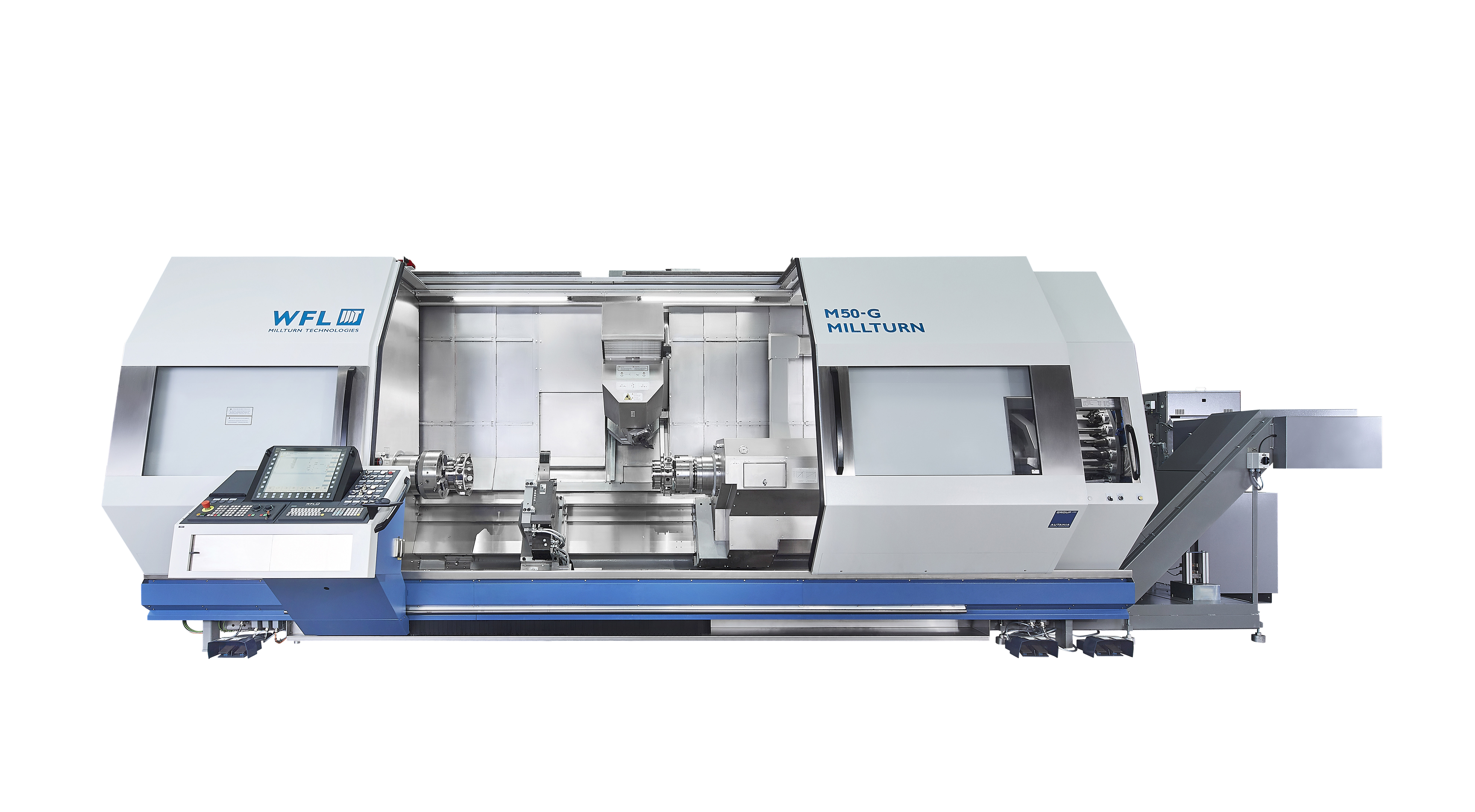

WFL Millturn Technologies GmbH & Co. KG is the leading supplier in the field of complete machining.

WFL is the only manufacturer worldwide that concentrates exclusively on the production of multifunctional complete machining centres. In many high tech companies today, the trade name MILLTURN stands for the central machine tool for the production of complex components with the highest precision. The modular design of the MILLTURN centres and individual special solutions guarantee perfect adaptation to the relevant manufacturing task.

With a MILLTURN, customers are not only purchasing a CNC machine that meets the very highest demands for quality and precision, they are also gaining an unbeatable competitive advantage. 30 years' experience in complete machining and thousands of solutions guarantee that WFL customers will get the most efficient and reliable machinery.

MATRIX PRECISION CO., LTD.

Product Description :

2080/3080 applies the FANUC controller and high speed grinding spindle, it will design the tooth profile and grinding parameters flexibly through the intelligent

conversations window software. The machinable workpieces include the standard worms

(ZK, ZI, ZN & ZA), dual-lead worms, ZC (Niemann) worms, thread plug gauges and rolling dies. The high efficiency and high-precision machining performance meet the worldwide top brand products in this field. 2080/3080 is your best choice.