Theme

Digital Transformation

Green Transformation

KING NICE TECH.CO., LTD.

Product Description :

▎Liquid filter purification, easy removal.

▎ Patented technology - easily correspond with liquid,water-soluble and Pure-oil Auto.

▎ Processing can easily recover swarf and sediment without stopping.

▎ The highest filtration accuracy can correspond to 5 nano.

▎ Solve the problem of long-term deposit on CNC water tanks such as iron chips,aluminum powder,fine sediment,etc.after machining.

▎ Widely used in metal cutting, aluminum machining,grinding process,engineering plastics, etc.

OSCAR E.D.M. COMPANY LTD.

Product Description :

1.Windows 10 Operating system with industrial CPU i3( or above)64-bit.

2.21.5" multi-touch screen with movable controller.

3.Equipped with digital voltmeter, current meter etc., to monitor the machine status easily.

4.Up to 6 axes control - XYZCUV - equipped by rotary table to satisfy complex job.

5.Color touch-screen on remote controller, unique design improves user convenience.

6.ECO stand-by mode: Equipped by a motion sensor for power saving.

OCEAN TECHNOLOGIES CO., LTD.

Product Description :

CNC Drilling EDM —RIVER 1000

Ocean Technologies' state-of-the-art product is designed with Five-axis tool center point (TCP) control

(X, Y, Z, A, B five-axis synchronization) drilling on irregular shared workpiece or special alloy steel parts.

The software can be break through and diffuser Shape Technologies to meet aerospace industry.

OSCAR E.D.M. COMPANY LTD.

Product Description :

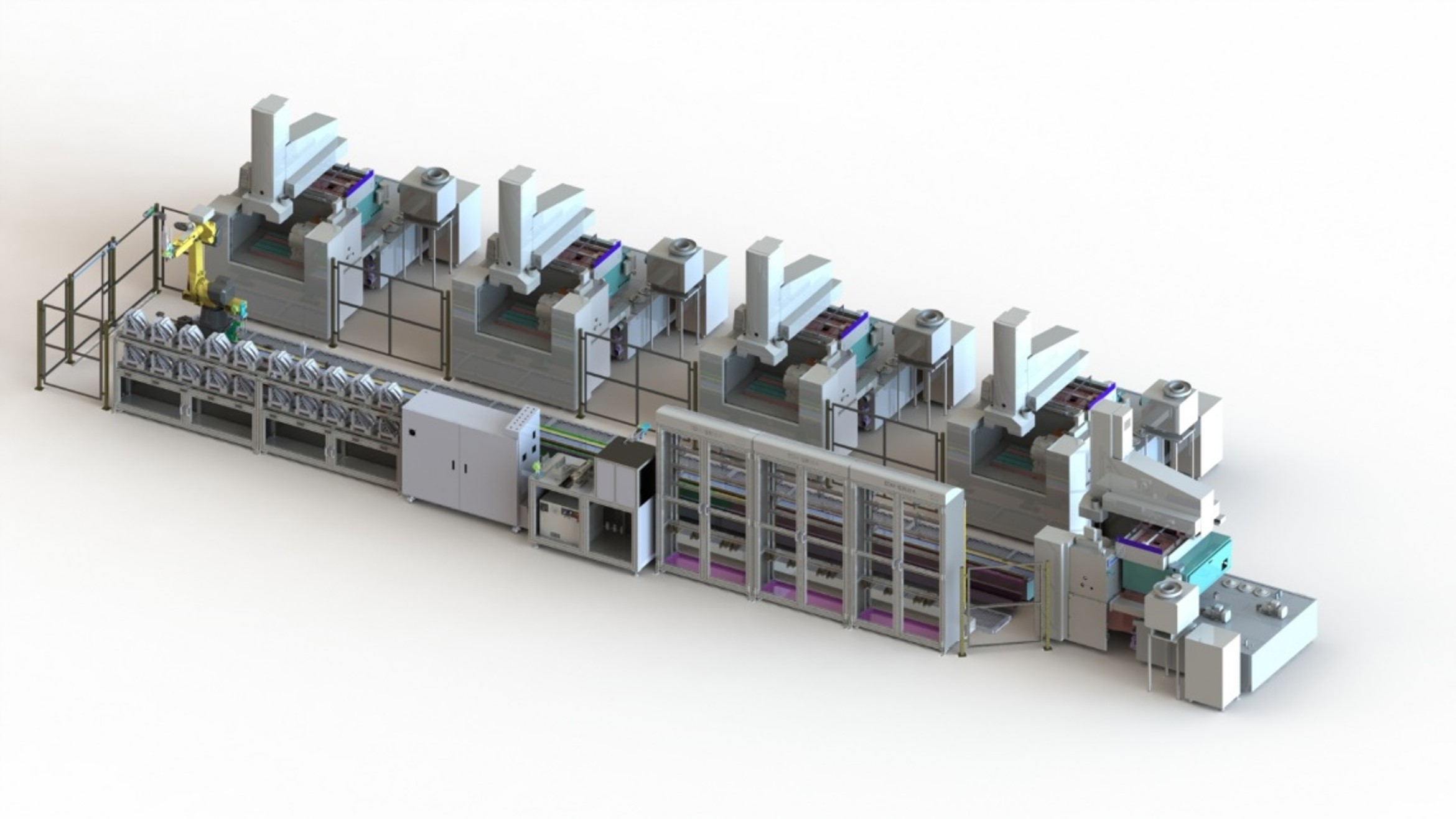

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year

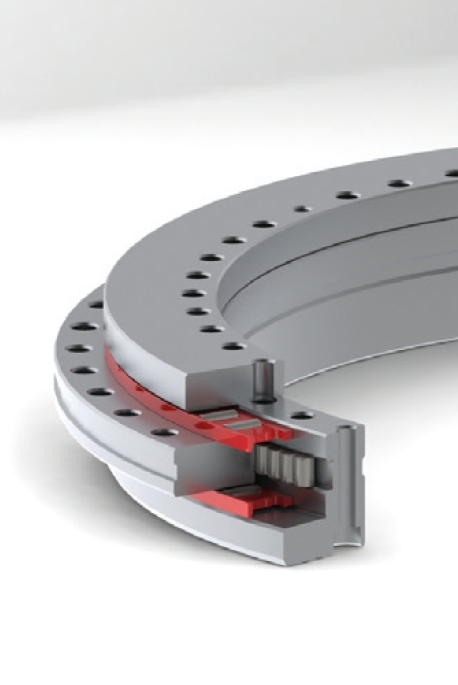

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

OSCAR E.D.M. COMPANY LTD.

Product Description :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

Product Description :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6