Theme

Digital Transformation

Green Transformation

OSCAR E.D.M. COMPANY LTD.

Product Description :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.

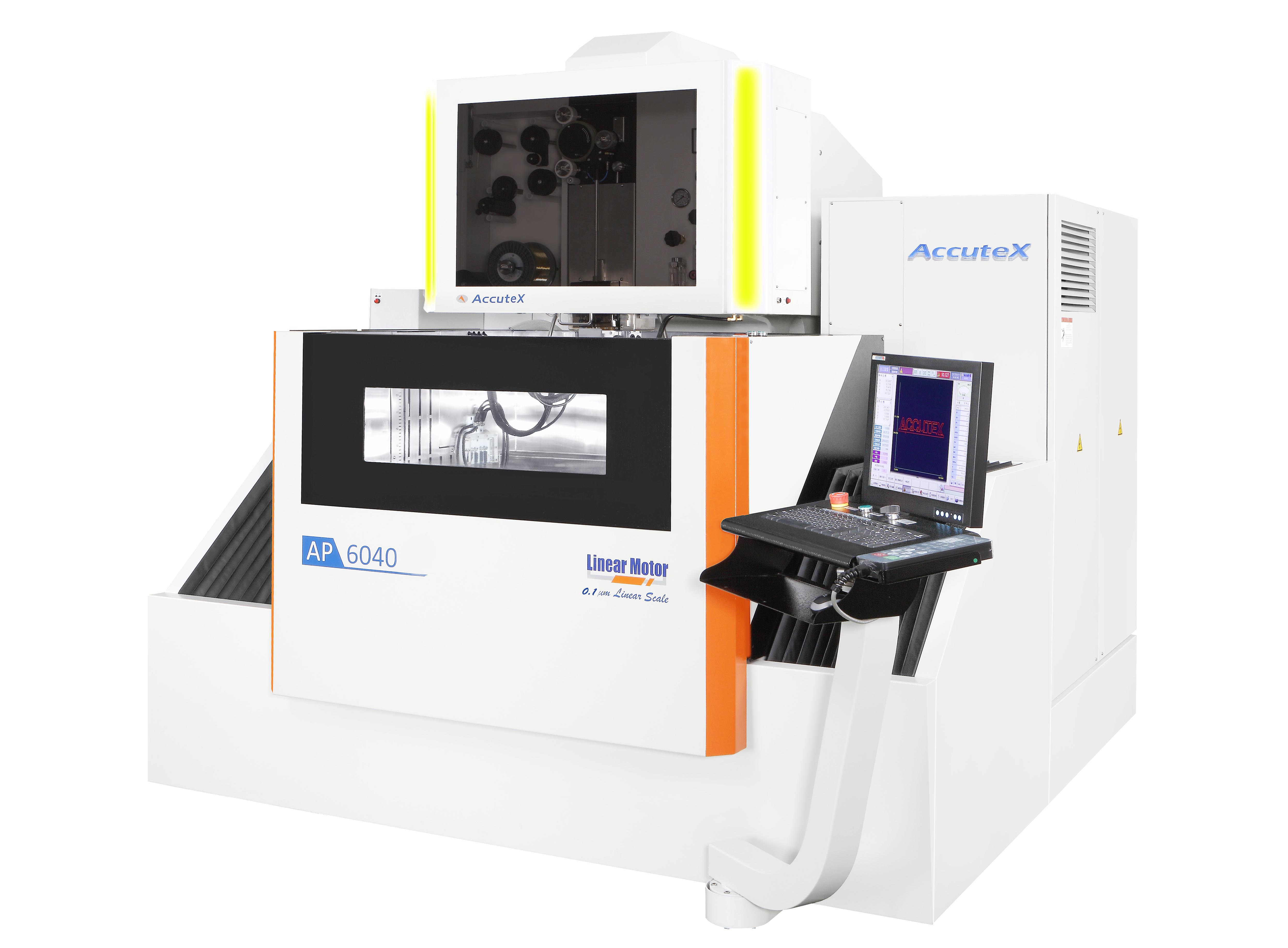

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

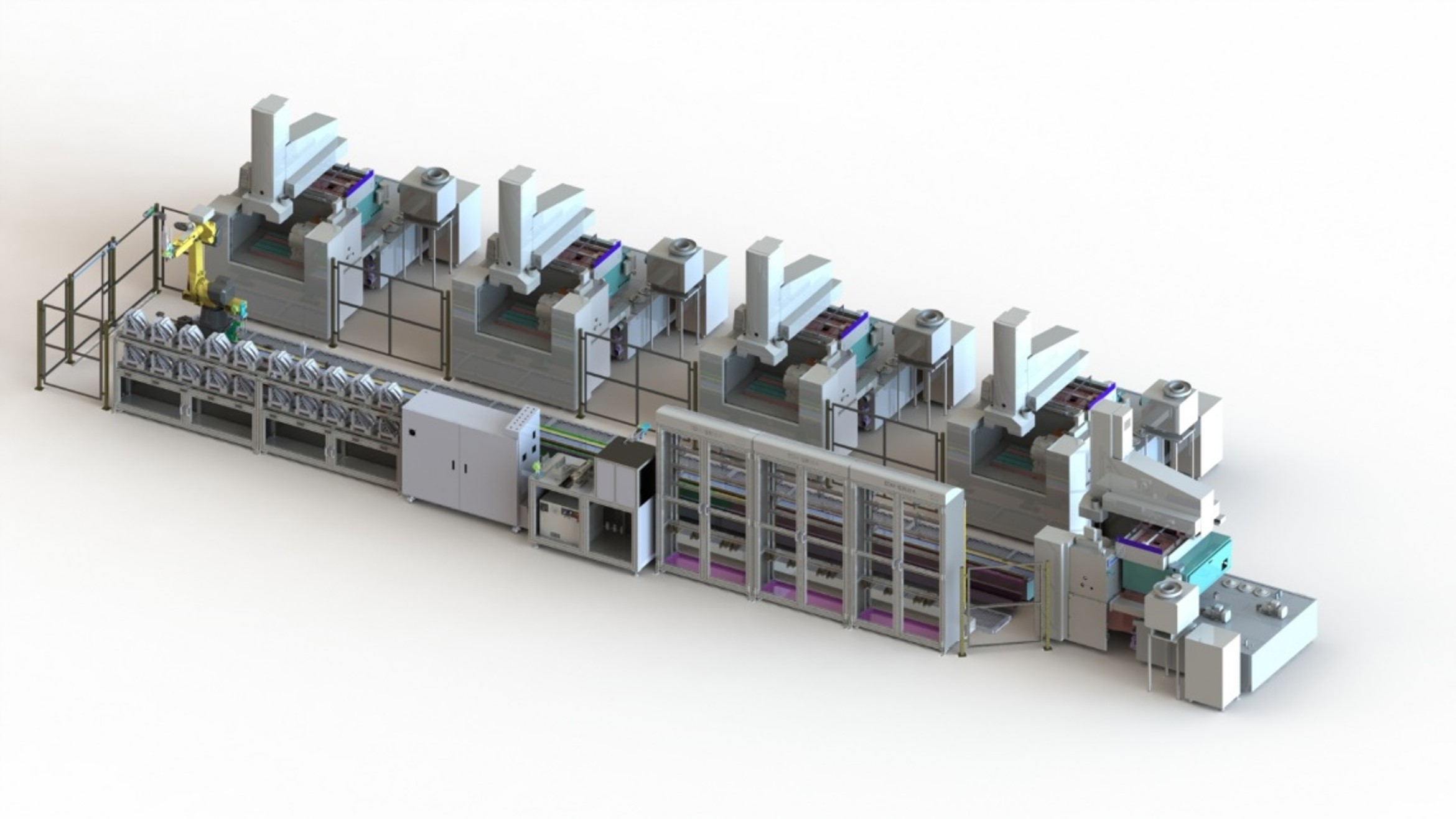

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

AccuteX machine is capable with industry 4.0 who has M2M (machine to machine) protocol

to collaborate with Robots and other machines. Flexible Real-time production can be made

by Intelligent Manufacturing Integration System to meet full-automation demand.

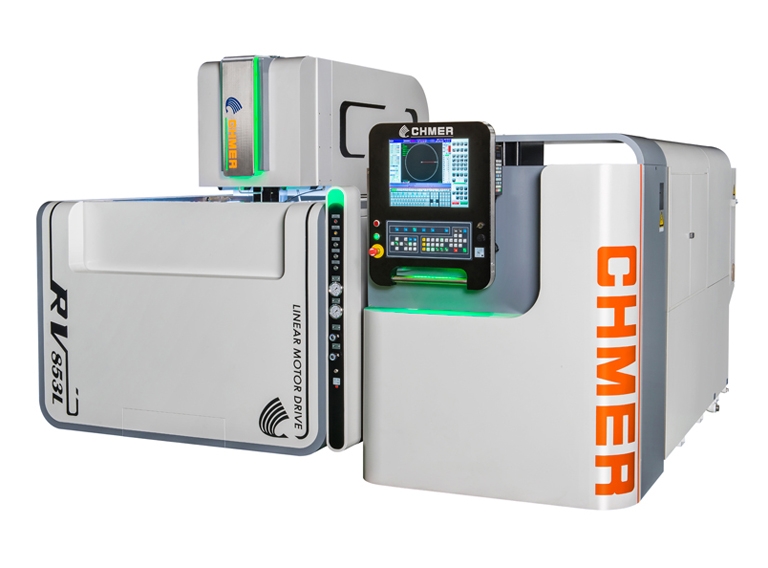

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

OSCAR E.D.M. COMPANY LTD.

Product Description :

Quick Integration

EX/EXD Series electrical discharge

machine, capable of easy integrated with

MES system, online measurement,

storage system and etc via OPCUA, API.

Smart Production line

Actual application on automobile moulding industry in

Europe. EX series sinker EDM integrated with MES and

milling machine where perform the production just-intime

without any interruption. By increasing 30% of

overall equipment effectivenss (OEE), 2 EDM will then

bring out extra 3,000 hours working time per year

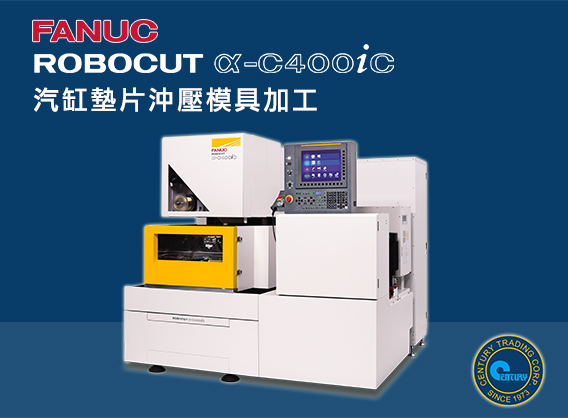

CENTURY TRADING CORPORATION

Product Description :

高性能

● 實現高速、高精度、高品質加工的新機器構造、新放電裝置、新放電控制

● 實現穩定加工的AI熱位移補償功能和各種形狀補償功能

● 實現更廣應用範圍的高精度旋轉軸ROBOCUT CCR

高效率

● 利用高可靠性的自動穿絲AWF3,實現連續無人運轉

● 利用消耗品管理功能和維護嚮導功能,協助日常維護

● 生產及質量信息管理工具ROBOCUT-LINK i

易操作

● 利用發那科先進的CNC和操作嚮導功能,實現優異的操作性

● 利用豐富的加工條件,協助高速、高精度、高品質加工

● 協助加工準備工作的自動化功能