Theme

Digital Transformation

Green Transformation

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive high rigidity hydrostatic rotary table, static rigidity greater than 400kgf/μm, Φ600/800table with a load capacity of >10000KG.

b.Mitsubishi/Fanuc controller available, with human-machine interface(HMI) which features fast communication and convenient for user-friendly operation.

c.The high rigidity of our hydrostatic spindle both radially and axially enables our spindles to produce a wide range of finishes-from speedy heavy cutting of >0.3mm to mirror-like finish.

d.To maximize stability and load capacity, the Y-axis(up/down) and the Z-axis (forward/backward) of the grinding wheel spindle are equipped with SCHNEEBERGER/THK/NSK lineal guideway.

e.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

f.Our products are on hundred percent designed and manufactured in Taiwan. To guarantee the stability of machine, all of the cast components go through a pressure relieve process

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Product Description :

The brand-new product CNC Vertical Complex Grinding Machine SVG-E800 (SVG series), suitable for composite grinding of inner and outer diameters and end faces of various big cylindrical workpieces. Its mechanical structure adopts a double column type design, featuring high rigidity, high precision, high stability, and high efficiency. It is encased in aesthetically pleasing fully enclosed safety covers, and can be equipped with controllers from Fanuc, Mitsubishi, or the latest generation. With its conversational interface, operation is intuitive and easy. The grinding wheel spindle system is HSK-A100, 10000rpm, 18.5/15kw, capable of automatically changing wheel holders, with an ATC device capacity of 6 tools, and a spindle angle positioning system at 0 degrees/22.5 degrees, enabling various grinding processes with just one clamping. The workpiece spindle adopts a hydrostatic system turntable with a diameter of 800mm, maintaining axial movement accuracy <1μm. Models with turntable diameters of 600mm and 1200mm are also available. For further technical specifications, please contact the Sales Department of SIGMA CNC.

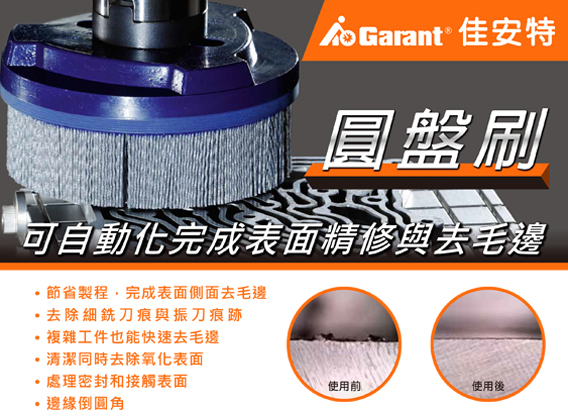

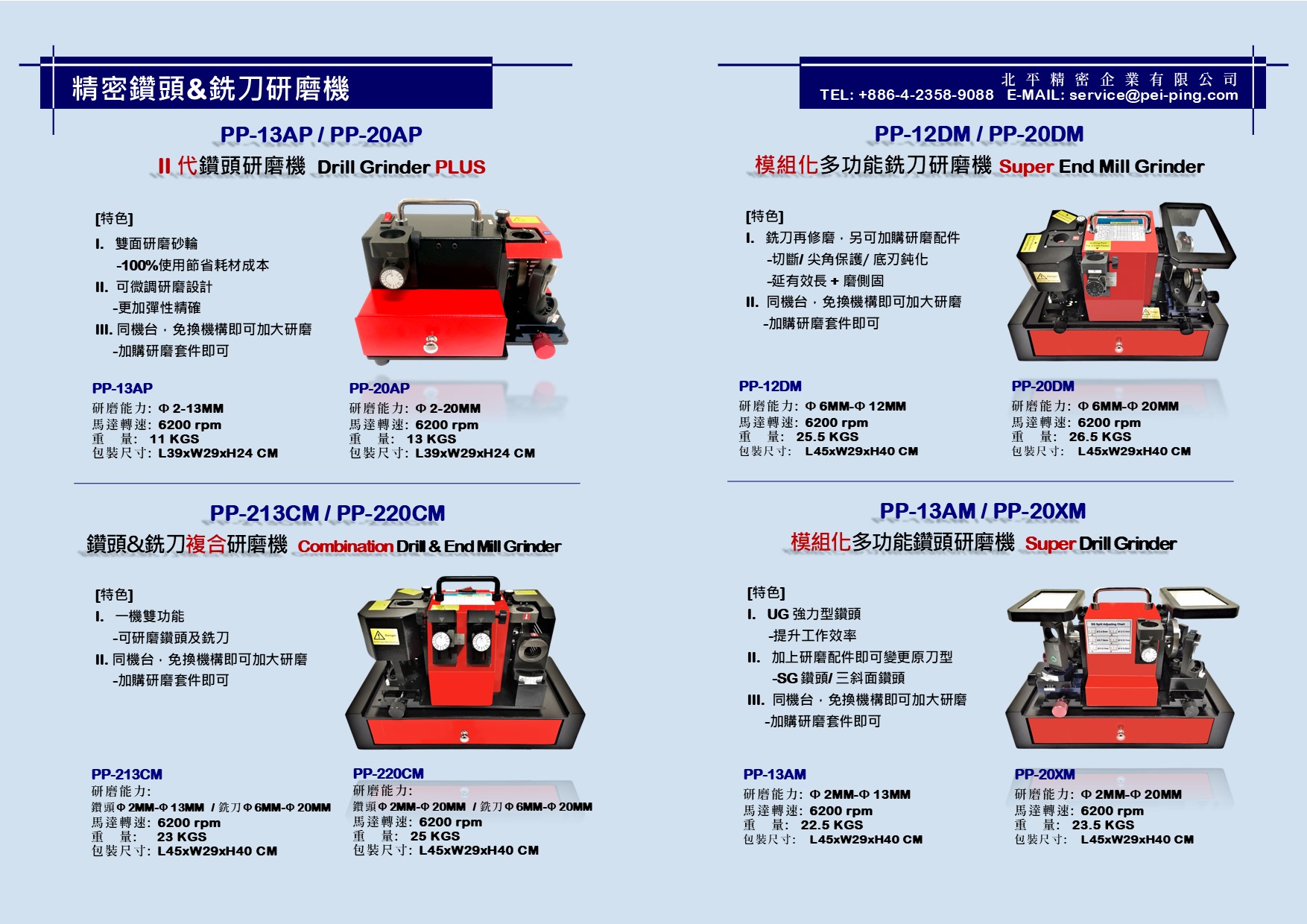

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

Fulson Industrial Co., Ltd

Product Description :

These high precision surface grinders have been specially developed and improved in recent years. The optimum span of double V crossfeed guideways is designed based on bending moment, Kinematics and supporting force. All essential castings are made of high grade of cast iron that is stress relieved through annealing to eliminate internal stress. With the greatest stiffness and stability of the castings, these machines are suitable for precision surface grinding. These grinders are offered with one-full-year limited warranty for mechanical and electrical parts.

GRINTIMATE PRECISION INDUSTRY CO., LTD.

Product Description :

a.Equipped with exclusive hydrostatic bearing spindle system with high rigidity, low friction, and no wear features.

b.Spindle rotation accuracy within 1μm.

c.Equipped with THK/NSK high precision ballscrews, ensuring the zero backlash feeding.

d.High rigidity and high vibration resistance capability on hydrostatic spindle, comparing to the conventional ball bearing/dynamic bearing spindle during heavy cutting, it represents the high machining efficiency for more than 10 times and can greatly reduce the machining time & labor cost.

e.Our machines are 100% designed and manufactured in Taiwan,all casting components are processed of stress relieving to ensure the machine stability.

JAINNHER MACHINE CO., LTD.

Product Description :

JHD-3205CNC is for internal/external grinding. The Maximum grinding O.D. is 320mm and grinding O.D. length is 200mm. The range of I.D.grinding is 2~200mm and maximum grinding depth is 150mm. One piece fabricated base, high rigidity box type structure.3Axes feeding system adopts high precision roller linear guide-way and double pre-tensioned ball screws.All sliding and rotating parts use automatic forced lubrication to ensure accuracy and longer use life of machine. The work head can do manual swing. The B and X axis are also applicable for taper grinding.

JHD-3205CNC is suitable for the parts which need high precision and complicated grinding requirements. The application such as:automobile/motor /energy & machine tool components/ Air & hydraulic components/measuring instruments/electronic parts and optical instruments.

FALCON MACHINE TOOLS CO., LTD.

Product Description :

Easy Setup, Flexible and Sealed for Grinding

The FVGC Series of vertical grinding machines is another prime example of Chevalier's position as the global leader in grinding technology. The series seamlessly increases efficiency and productivity for such industries as semiconductor, punch and aerospace, as well as other sectors for which these machines can be equipped. Workpieces in these fields primarily are a composite, single crystal silicon or brittle, along with other materials that present process challenges.