Theme

Digital Transformation

Green Transformation

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 2mm-13mm Twist Drill Re-sharpening , Angle 90°-140°

For 3mm-12mm End Mill Re-sharpening

Twist Drill:

1. Precise Grinding Results , Precision Assurance within 0.02mm

2. Easy to Operate , grinding a drill within 10 seconds.

End Mill

1. Adjustable Cutting Face Angle and Width

2. Easy to Operate , grinding a End Mill within 60 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14.2 kgs.

MATRIX PRECISION CO., LTD.

Product Description :

ZHS-3040 combines FANUC controller and PC, it applies linear motors and direct drive motors, developing out the six-axis-control and four-axis-move high-precision grinder. ZHS-3040 can sharpen the blade of straight and helical hobs, it can also sharpen shaper cutters and Power Skiving cutters by options. Self-developed intelligent conversation window software is easy for operation. It meets the brilliant high-precision and high-efficiency performance. One machine with multi- purpose, ZHS-3040 is your best choice.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 3mm-20mm End Mill Re-sharpening , Adjustable Angle

Precise Grinding Results , Precision Assurance within 0.02mm

Center Cutting Available

High Accuracy Balance between each flute of the End Mill

Easy to Operate , grinding an End Mill within 1 minute.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 14 kgs.

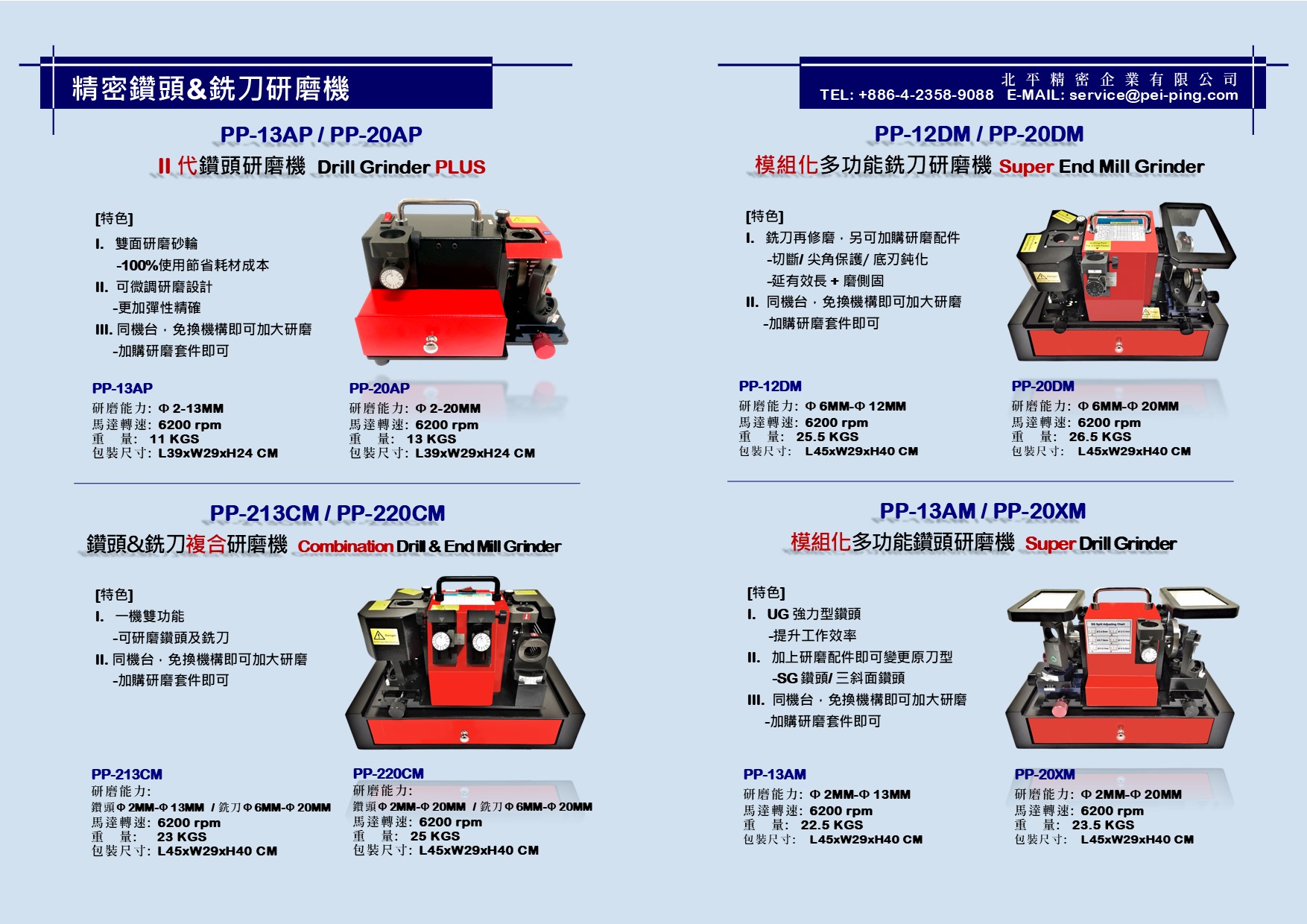

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 34.1mm-52mm Twist Drill Re-sharpening , Angle 118°-140°

Precise Grinding Results , Precision Assurance within 0.1mm

Easy to Operate , grinding a drill within 10 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

TAIWAN MORE-CASH VILLAGE CORP.

Product Description :

For 2mm-34mm Twist Drill Re-sharpening , Angle 90°-140°

Easy to Operate , grinding a drill within 10 seconds.

Special Design High Accuracy Alloy Steel Collets

Accurate Grinding consumption 0.2mm

High Efficiency DC motor

Stable Quality Diamond Dust Grinding Wheel

Considerable Design, Invisible Tool Box, Delicate & Friendly Use

Portable Design with only weight 21.5 kgs for Machine, 13.6 kgs for Tool Box