Theme

Digital Transformation

Green Transformation

YIH KUAN ENT CO., LTD.

Product Description :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

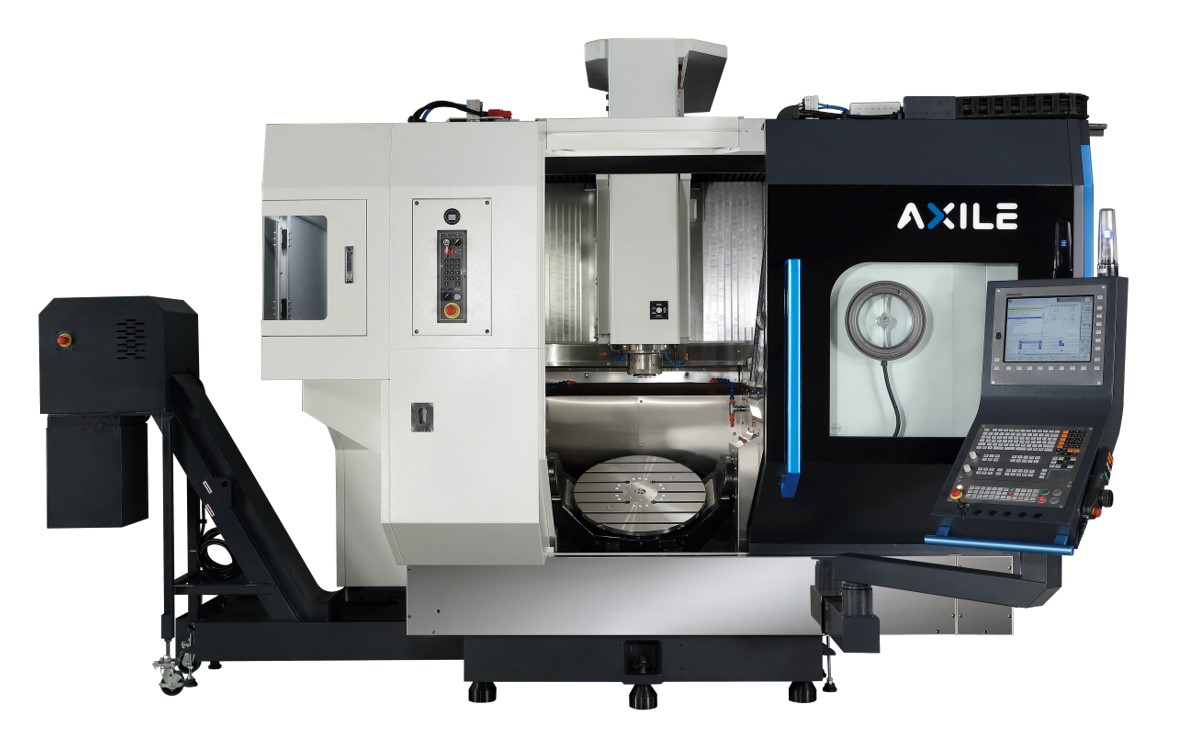

BUFFALO MACHINERY CO., LTD.

Product Description :

With a rotary table diameter of 600 mm, the G6 is a compact vertical machining center designed for agile, smart machining of smaller workpieces requiring complex geometries and intricate features. This highly versatile VMC delivers full 5-axis CNC machining, with the built-in spindle moving along the X,Y,Z-axis, and the table moving in rotary C-axis and swiveling A-axis.

The G6’s perfect balance of speed and precision makes it the perfect option for job shops and production lines seeking an upgrade in machining capabilities, delivering high removal rates, excellent surface finishes, and maximum production efficiency.

In addition to the high-performance G6 model, AXILE also offers the G6 MT, which combines both milling and turning in one machine, greatly increasing operational flexibility. By reducing set-up times and potential clamping errors, the G6 MT can efficiently machine a wider variety of parts, including cylindrical components.

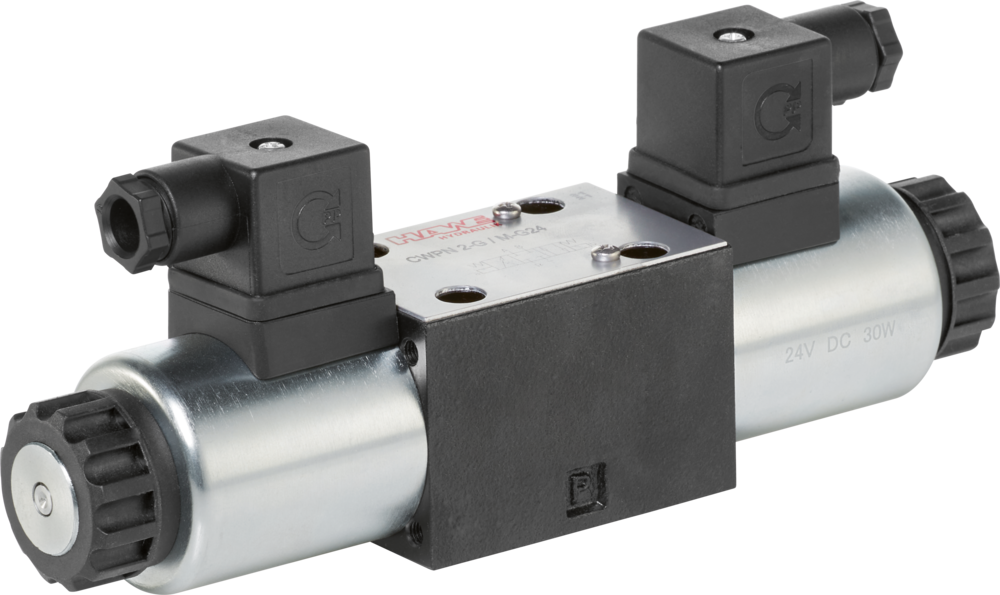

HAWE Hydraulik Singapore Pte. Ltd. Taiwan Branch

Product Description :

Directional spool valves are a type of directional valve. They control the direction of

movement and the velocity of single and double-acting hydraulic consumers.

The directional spool valve type CWPN is a 4/3- or 4/2-way directional valve with standard connection pattern NG 6 (CETOP 03). It is directly actuated and a binary

valve.

The directional spool valve type CWPN can be flexibly combined with the common HAWE valve banks and compact hydraulic power packs. It can also be mounted on customer-specific manifolds or sub-plates.

Features and benefits

■ Universally usable thanks to standard connection pattern NG 6 (CETOP 3) according to ISO 4401-03 or DIN 24 340-A6

■ Modular system with various circuit symbols and actuation variants

■ Optionally also available with additional valves in port P

Intended applications

■ Machine tools

■ Wind turbines

■ Solar power plants

■ Industrial hydraulics

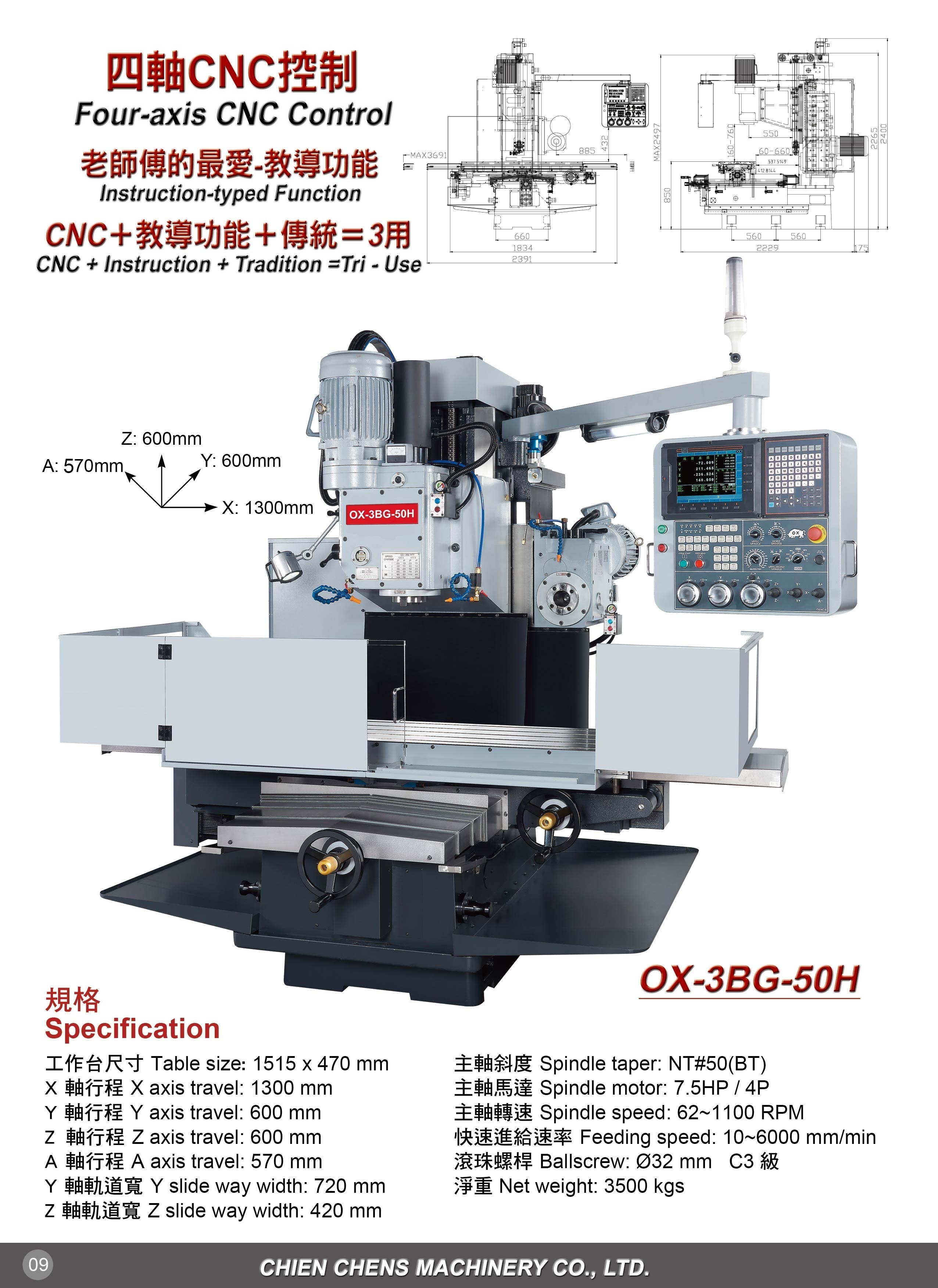

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 760 mm

Z Slide way width: 420 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 2P

Spindle speed: 62~1100 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3200 kgs

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

Product Description :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

REN AN INFORMATION TECHNOLOGY CO., LTD.

Product Description :

Just like the real CNC machine, equipped with exactly same overall appearance, actual handwheel and real machine operation panel as numerical control machine.

Solving the difficulties of real machine: precise, complicated and very expensive.

With CNC Simulator, everyone can learn CNC machine operation and accumulate hands-on operation skills.

CNC training machine is equipped with exactly same overall appearance, actual handwheel and real machine

operation panel as numerical control machine. Its purpose is to train students for accumulating CNC machine operation skills (program transmission, programming, tool selection, tool compensation and alarm clear )

Overall design is more attractive, and it emphasizes on interaction to make students less mistakes happened.

Not only decreasing learning cost but also letting students work and learn in the safe environment.

PAO FONG INDUSTRY CO., LTD.

Product Description :

PF-8S1500CNC Bed type 4-axis vertical Bed

type milling machine developed by PAOFONG.

Table size: 1730 x 400 mm )

Travel:

X = 1500 mm

Y = 500 mm

Z = 550mm

Spindle Taper: NST#40 Machine.

It is mainly used for machining of large

Centroid 4 Axes CNC Table and heavy-duty chip removal capacity.

This large machine bed is developed for large-sized 4th Rotarl Table.

Table design It is built with premium cast-iron .

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

WELE MECHATRONIC CO., LTD.

Product Description :

1.高剛性高穩定性結構

A. 底座:機器底座採用整體式鑄件,有效確保機器剛性。Z底座採4線軌設計,全行程範圍內直接落地支持,有絕佳的剛性及穩定性,確保整體長期幾何精度。

B. 滑座:滑座採用整體式鑄件,支撐於Z底座上,4線軌設計增加滑座負載剛性。

C. 立柱:立柱採用整體式鑄件,有效確保機器剛性;且固定不移動,大大減少主軸移動行程中所帶來的幾何精度誤差影響。

2. XYZ三軸及W軸導軌均採用先進的超重負荷型「滾柱」線性導軌,大幅度提高導軌「剛性」和「重切削能力」,也繼續保有「低摩擦力、低磨耗、低遲滯現象、低失位量、高速度、高精度、高動態特性、高壽命、不需調整」等線性導軌的優良特性。

3.XYZW四軸的均有過負載保護,如因誤操作造成撞機,可有效降低對機器的損傷。

4.雙編碼器回饋裝置(配置於XYZ三個進給軸),B軸採用(圓光栅-角度編碼器) 廠牌:發格Fagor。

5.主軸箱等關鍵零件係利用「大型臥式搪孔機」及「大型高精度三次元量測儀(三座標量床)」確實達成應有的加工精度,確保優良的組裝基礎。

6.鞍頭:110主軸系統配備搪孔軸直徑110mm,搪孔軸行程W=500mm、3500 rpm(兩檔齒輪箱)。搪孔軸為氮化處理高硬度合金鋼件,前段支持使用傳統的硬化襯套外,後段附加線性導軌的加強支持,借助滾動低磨耗的特性,增長搪孔軸的精度壽命。

7.主軸前軸承採用直徑150mm的高精度主軸軸承,加上改良設計的軸承配置及潤滑設計,有效的提高主軸剛性和壽命。

8.主軸鬆刀採浮動式抓鬆刀裝置,鬆刀時不會施力於主軸軸承上,可長保主軸最佳精度;另,新式鬆刀缸配置設計,可使主軸於任一行程(W軸)位置換刀。

9.特殊設計的自動潤滑系統;潤滑油與切削液分開, 單獨收集可確保切削液的穩定性及工作環境的清潔。

10.刀庫採立柱側背式設計;刀庫與立柱接合,不同於落地型式,立柱固定不移動,刀庫與鞍頭配置可達成左右平衡架構,提高W軸動態穩定特性。

11.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的幾何精度,確保機器應有的精度和壽命。

12.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

13.電氣箱採全密閉式循環熱交換系統,內部配線均參考德國工業安全標準,電源部份與訊號線區隔,以增加機器使用上的安全。

14.搭配高規格的Fanuc 0i MF Plus數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、1280米記憶容量、Ethernet網路接口、Flash記憶卡插口、Manual Guide i圖形對話式編程、剛性攻牙、手動剛性攻牙、AI contour control II等多項高規格功能,能經濟有效的滿足各種使用需求。

15.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

16.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

17.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。