Theme

Digital Transformation

Green Transformation

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■Double built-in spindles with high accuracy C axis, max. speed 10000 rpm.

■The large number of available tools increases your productive time, efficiency to process turning, milling, drilling and back machining.

■Front tooling system provides 6 O.D. tools, 5 I.D. tools and 3 radial live tools plus 2 expansion adapter live tool units.

■Back tooling system on Y2 axis can have a max. of 8 live tools, also provide two deep drilling holders beside the sub spindle.

MATECH INDUSTRIAL CO., LTD.

Product Description :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

MING YANG MACHINERY CO., LTD.

Product Description :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

Product Description :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. External auto loading/unloading SPM

2. Its feeding capabilities are O.Dφ6~φ35 mm, max length 40mm.

3. Its feeding mechanism is placed outside of machine to keep mechanism from chips and oil stain.

4. Adjustable guideway is suitable for round/hex shape workpiece alone with rotary cylinder and fixture, which can make hex material positioning in short time.

YING HAN TECHNOLOGY CO., LTD.

Product Description :

5-AXIS VERTICAL MACHING CENTER BELONGS LINEAR WAYS ON THREE AXES, X, Y, Z -AXIS TRAVEL: 800x600x550mm, MEEHANITE CAST IRON IS TEMPERED FOR STRESS RELIEF TO ENSURE STRUCTURAL STABILITY WITHOUT DEFORMATION. REINFORCED COLUMN BASE GREATLY INCREASES STRUCTURAL STRENGTH AND WILL EXHIBIT ULTRA-HIGH STABILITY DURING HIGH SPEED OPERATION. WITH THE EQUIPMENT OF CNC TILTING ROTARY TABLE, THE MACHINE IS ABLE TO PERFORM 5-AXIS MACHINING, IT CAN MACHINE COMPLEX, MULTI-SIDED PARTS IN A SINGLE SETUP, THEREBY REDUCING SETUP TIME WHILE INCREASING PART ACCURACY.

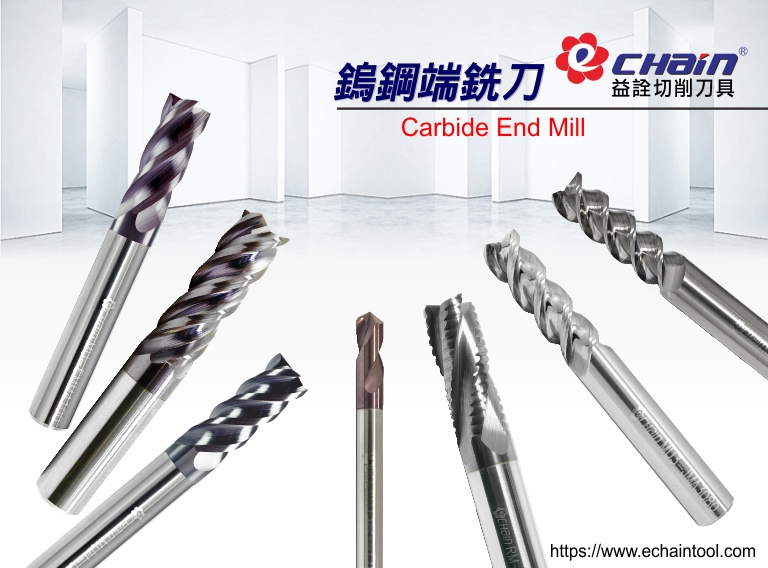

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

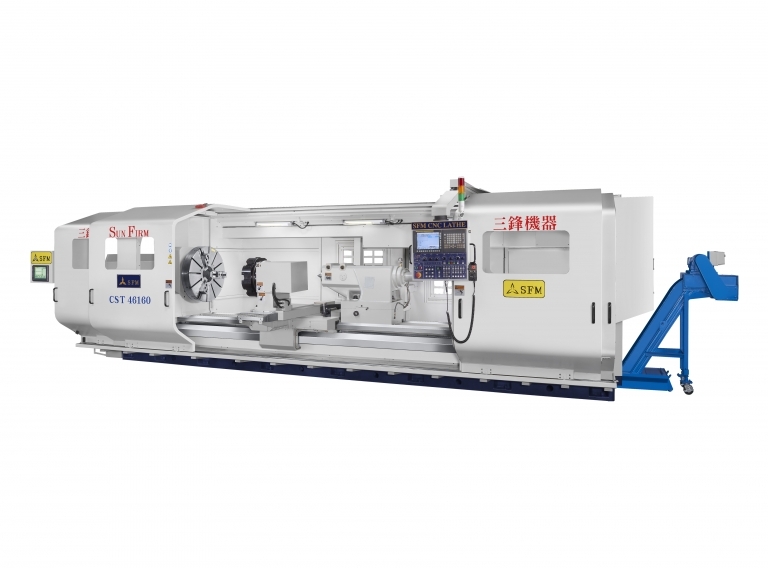

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.