Theme

Digital Transformation

Green Transformation

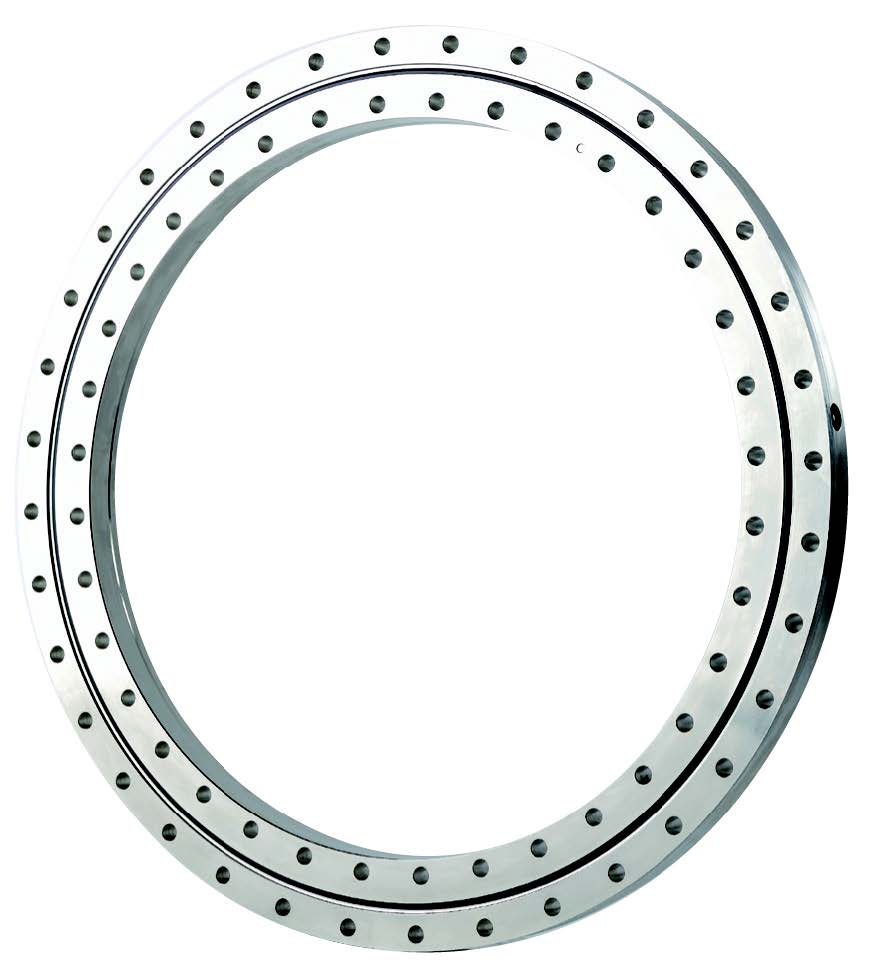

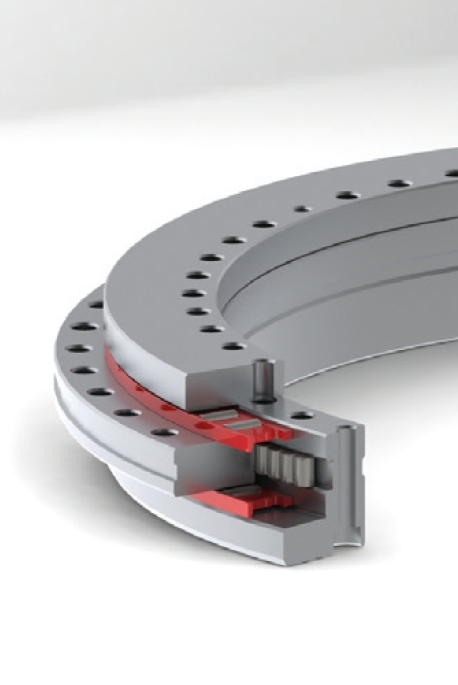

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.

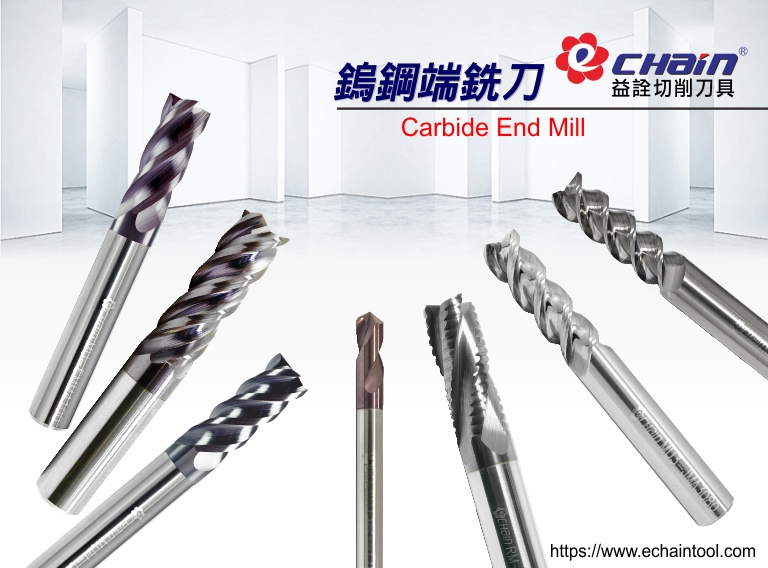

ECHAINTOOL PRECISION CO., LTD.

Product Description :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

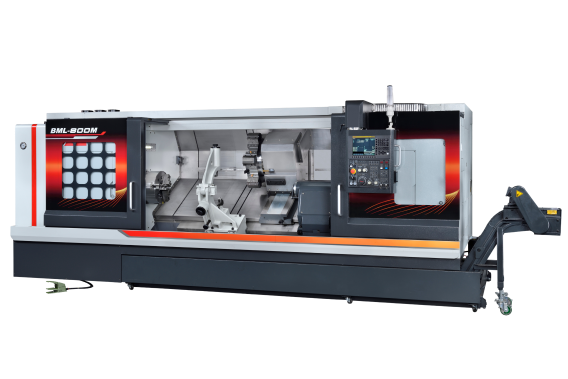

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

The PJ-30VT is a frequency control (variable volume) complex system. Supplied for maximum 70bar (1000psi), 100bar (1500psi) or 140bar (2000psi) working pressure to Swiss Lathes, CNC Lathes, and Machining Center. This system carries the LIS Automatic patent high-performance centrifugal filtration device, extended the lifetime of the consumables, and also lets the system more stable. Designed for the restricted tank capacity machine, reduced the problems of the tank foaming and overheat effectively.

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

YK series is designed specially for small and high precision parts with powerful processing capacity, stable quality and accuracy. It is the best choice for various manufacturers of automotive and motorcycle parts, electronic parts, instrument parts and medical equipment parts.

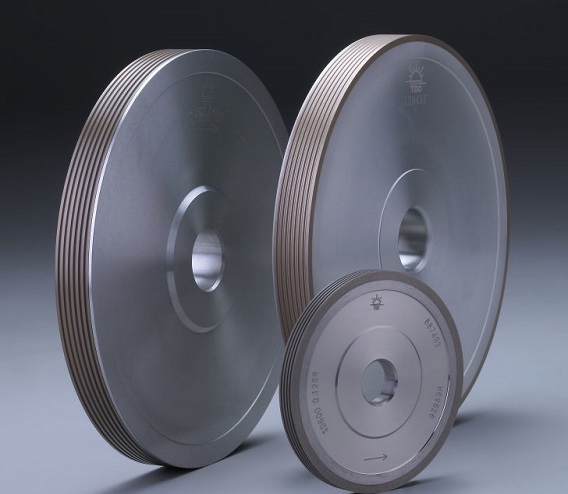

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Tungsten Carbide Blade Tool Processing

1. Excellent grinding ability, significantly reducing spindle load, save processing time and cost.

2. Tough texture and wear resistance characteristics to achieve the maintenance of tool dimensional accuracy.

* Processing Material | Tungsten Carbide

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

Product Description :

* Processing Method|Grinding

* Applications|Semiconductor Material Processing

* Silicon wafer edge grinding wheels require strict shape precision and wear resistance, and require stable grinding capabilities, so metal bond grinding wheels can be used. We can provide single groove or multi groove, integrated coarse and fine grinding wheel according to customer’s requirements.

* Processing Material | Silicon Crystal

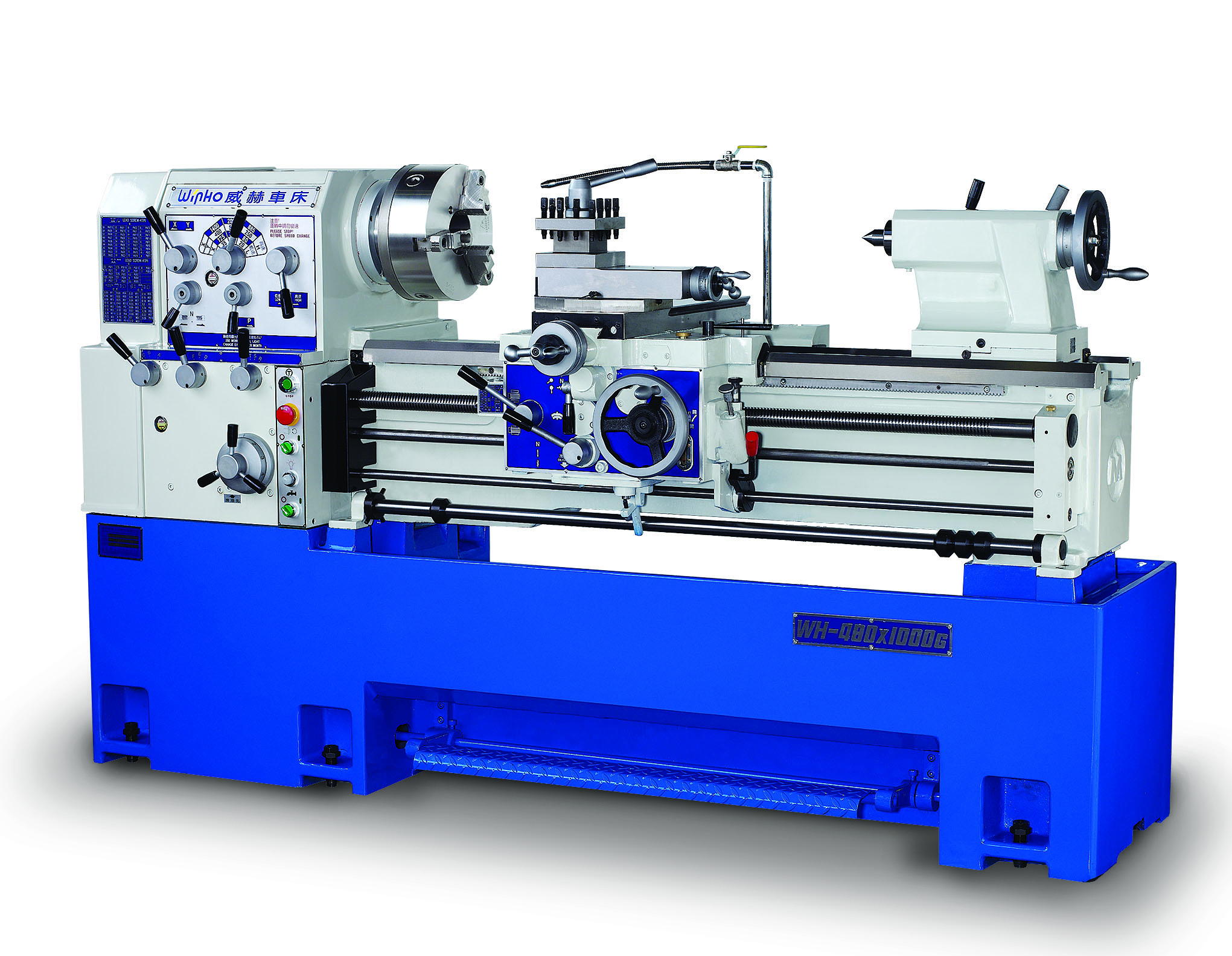

WIN HO TECHNOLOGY INDUSTRIAL CO., LTD.

Product Description :

High Speed Precision Lathe

1. Selective bed width:

S series: 300mm.

M series: 350mm.

L series: 400mm.

2. Varied spindle bore diameters:

S series: O58mm / O80mm (Option).

M series: O85mm / O105mm (Option).

L series: O85mm / O120mm (Option).

3. With FAG or SKF precision bearings installed on

spindle, maximum cutting depth can be 8mm on

50mm diameter and best roundness 0.003mm

(200mm long).

4. Equipped with plastic rear gears, shafts and

gears inside headstock are well protected if crash

should occur (S430 & S480 Series).

5. Thermal treated and precision ground alloy

gears.

6. Universal gearbox for both imperial and metric

thread-conversion table also attached.

7. Tracks of cross slide and bed are well lubricated

with lubrication pump (manual).

8. Overload device to ensure safety when

operating.

9. Wear-resistant phosphor bronze lead screw

nuts.

10. Durable reservoir oil bath type cross slide (for S

series).

11. Thermal treated Meehanite bed casting.

12. One-piece base for high rigidity and low

vibration.

13. High-capacity coolant tank offers sufficient

coolant output.

14. All series certified for CE.

Reservoir Oil Bath Type Cross Slide

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

MANFORD MACHINERY CO., LTD.

Product Description :

With linear guideways on X and Z axes and 30M/Min rapid traverse, SBL series is absolutely an ideal solution for high-speed turning applications.

Features

● 30゚slant bed structure.

● Meehanite cast iron for all structural parts.

● Hardened and ground ballscrews for precise traversing and consistent machining accuracy.

● Fully enclosed splash guard ensures a safe and clean working environment for operators.

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

TAIWAN MACHINE TOOL CO., LTD.

Product Description :

Strong casting and the perfect boxway stucture provides excellent cutting capacity for TTB-20MW Series. Sub-spinfle with milling function and Y-axis can satisfy customers' miltiple needs.

-The one cast base incorporates FEM analysis to achieve its optimal ribbing and structure to further enhance machine rigidity and stability.

-The 30 degree slant bed design has low center of gravity for easier swarf management and better erogonomic design. The TTB-20MW Series also offer optional rear type chip conveyor.

-To make sure the usage life of Y-axis ballscrew will get longer, there are three bearing on Y-axis ballscrew to enhance the support for pressure from top.

-The TTB-20MW Series can achieve maximum 20m/min for X axis and 25m/min for X axis. And the servo motors adopt absolute encoders for faster and more reliable positioning.