Theme

Digital Transformation

Green Transformation

LINTRONIX CO., LTD.

Product Description :

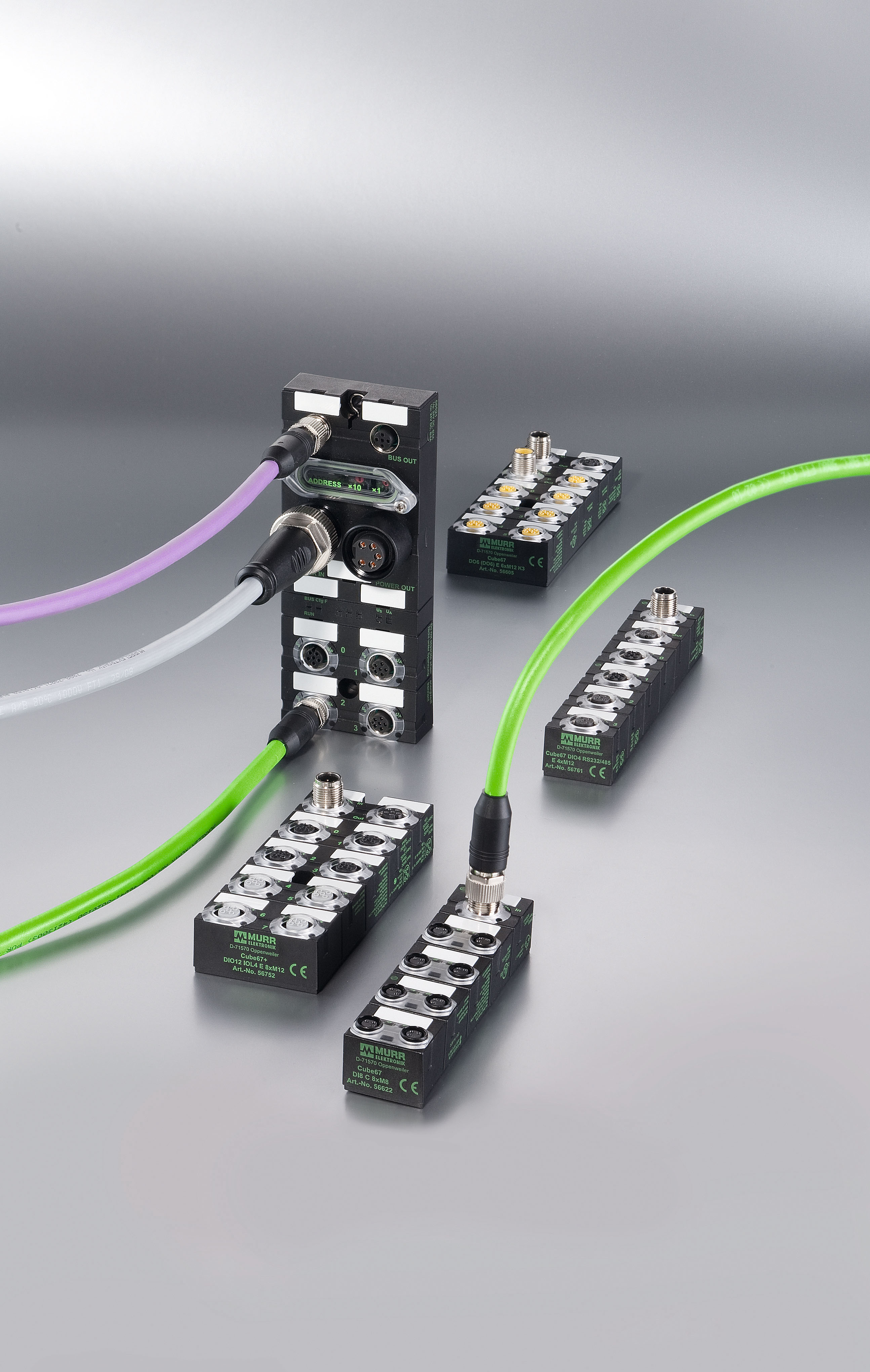

德國 Murrelektronik的策略

•減少控制箱空間:採用遠端IO 與IP67Ethernet switch

•即插即用可配置I / O系統

•使用Cube67+複合電纜技術降低佈線

•全面的診斷=輕鬆調校,並減少停機時間

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

■Choose Machine : Tsugami S205/S206■Detailed specifications

▼Speed ratio :1:1▼Maximum speed : 5000RPM▼

▼Tool clamping : Utilis no.119287▼Angle adjustment : ±20°

▼Reference code : 3281-Y450

https://www.songgia.com.tw/en/products/thread-whirling-unit-tssa545201

HAINBUCH GmbH

Product Description :

HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings are made of case-hardened chromium-nickel-steel and have segments that are extremely hard and rigid. All contact surfaces are completely ground in one operation guaranteeing optimum concentricity.

Mandrels with hexagonal clamping geometry, the MAXXOS mandrels. are the optimized version for round MANDO mandrels. Thanks to the hexagonal geometry, a previously unattained clamping force and rigidity with the best precision is now achieved for internal clamping. The robust and powerful clamping mandrel delivers first-class values in terms of dirt density. The force is transmitted by positive locking, in addition to optimum process reliability and long maintenance intervals.

WALRUS PUMP CO., LTD.

Product Description :

TPR(S) is a non self-priming, vertical multistage centrifugal pump,consisting of a base, pump head, pump body and an outer sleeve.

The base has in-line suction and discharge ports, and all seals are maintenance-free.

CHUMPOWER MACHINERY CORPORATION

Product Description :

精密鑽夾具適用於鑽床、銑床加工機、切削工具機、加工放電機、攻牙機、CNC車床、工具機等配件、主軸配件(四瓣爪、噴水頭)

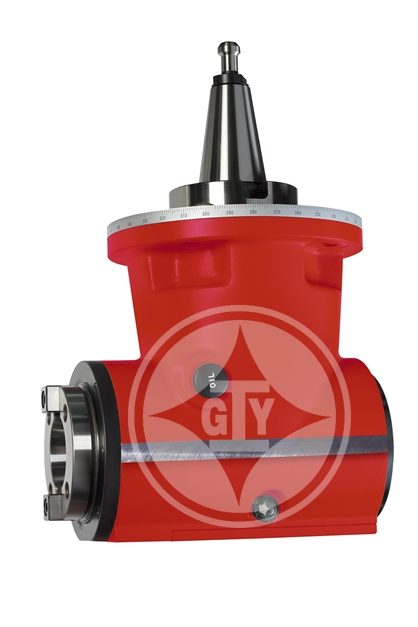

XIN GONG YANG MACHINERY CO., LTD.

Product Description :

◎Spindle Taper:ISO 50

◎Outside Diameter of Flange:Ø250 / Ø300

◎Max. Speed:3000RPM

◎Applicable work:

0~800RPM-light cutting;

800~3000RPM-finish milling

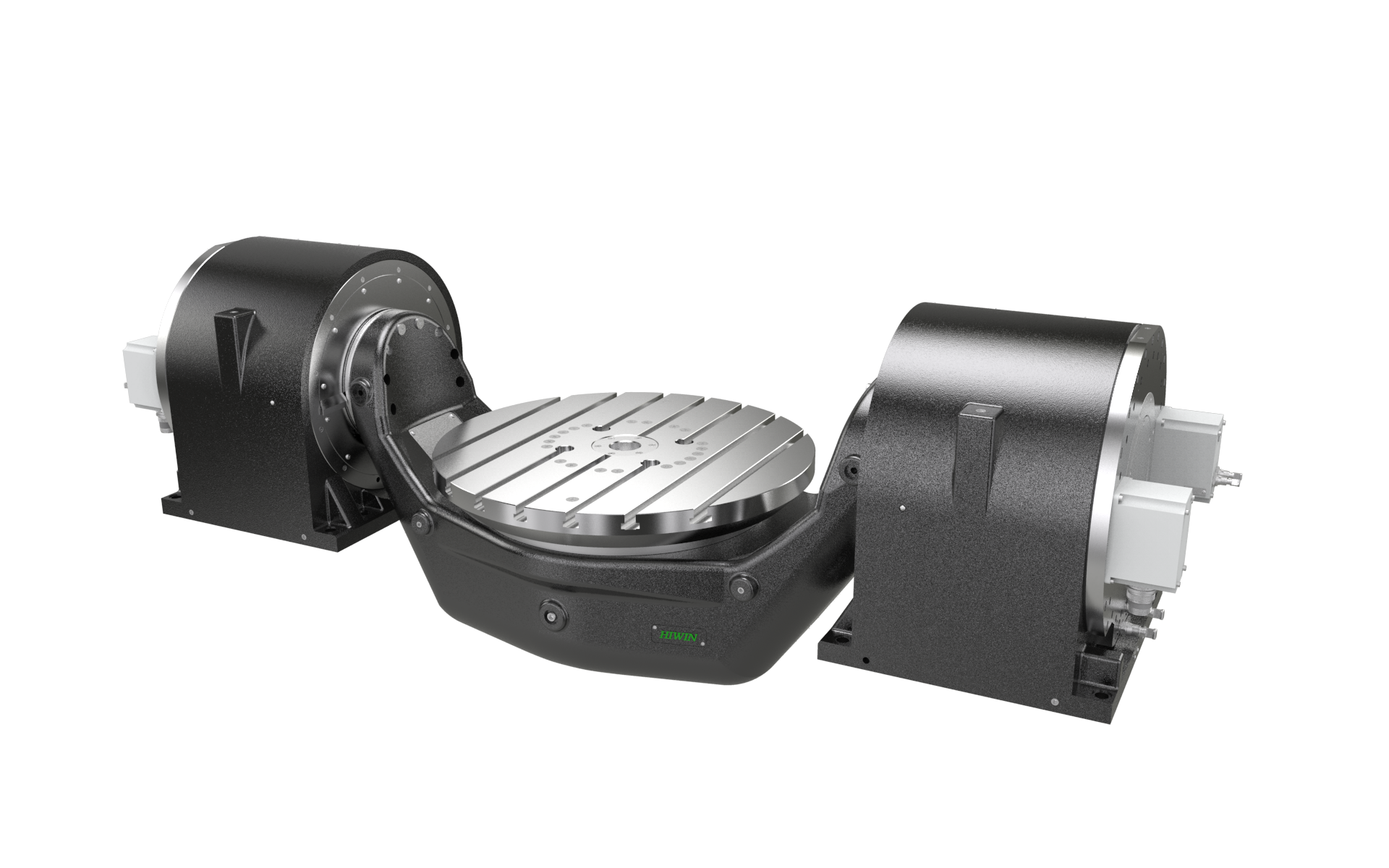

HIWIN TECHNOLOGIES CORPORATION

Product Description :

HIWIN Torque Motor Rotary table equips with HIWIN’s water cooled direct drive motor. With features of high torque, high precision and zero backlash including crossed roller bearings and pneumatic braking system, which plays an important role in the multi-axis machines. These rotary tables can increase the competitiveness of the machines with high speed, high performance, high precision and one time machining program reducing the errors during disassembly and clamping of components between multiple machines to complete the machining task, achieve the ability for complicate curve machining in one setup.

① The underwater rotary table (RCV-E series), lightweight insulation, up to IP 68 -rated waterproof and dustproof, suitable for discharge rotary cutting and grinding processing applications.

② Double axis rotary table (RAB/RAS Series)

Key component for high end multi axis machining center.

③ Single axis rotary table (RCV/RCH Series)

Widely used in turn-mill machining centers with speed up to 2,000 RPM.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.