Theme

Digital Transformation

Green Transformation

Otennlux Lighting Technology Co.,Ltd

Product Description :

Otennlux LED intelligent signal lights use IO-Link interface, flexible and versatile, and

diversified applications, providing reliable control solutions for Industry 4.0 intelligent

automation industry. Reduce wiring, increase data availability, remote configuration and

monitoring, simple equipment replacement and advanced diagnosis, improve process

efficiency and increase machine availability.

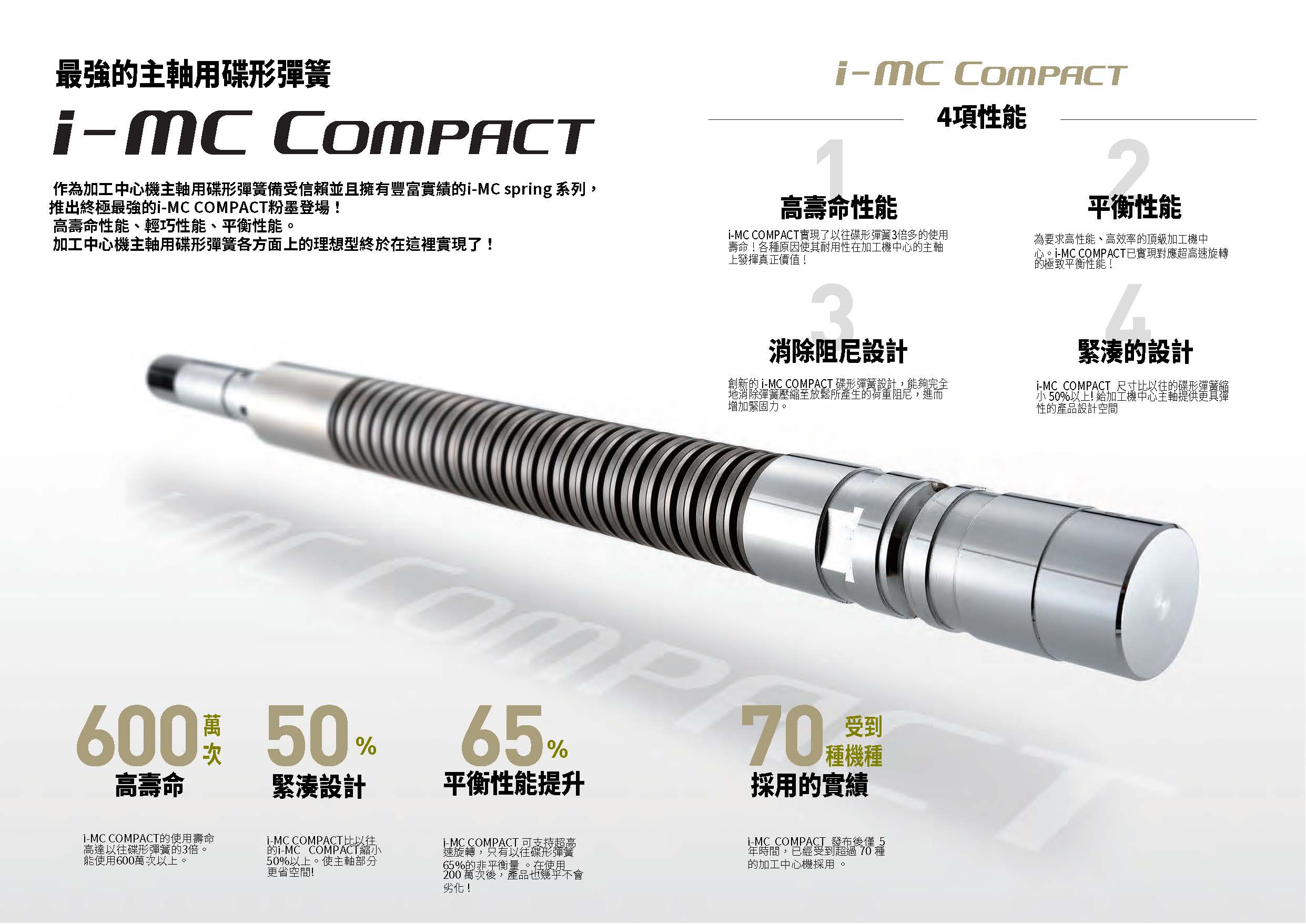

Tokai Spring industries, Inc.

Product Description :

i-MC spring series has established a strong trust and reputation as disc springs for the main spindle on machining centers among manufacturers. i-MC COMPACT is a new and innovative product of i-MC spring series.

Long-life performance, compact performance and balance performance.

In all of these aspects, this new product achieves the ideal form of disc springs for the main spindles on machining centers.

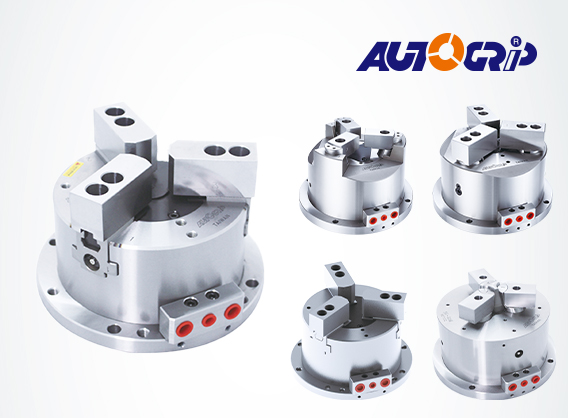

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

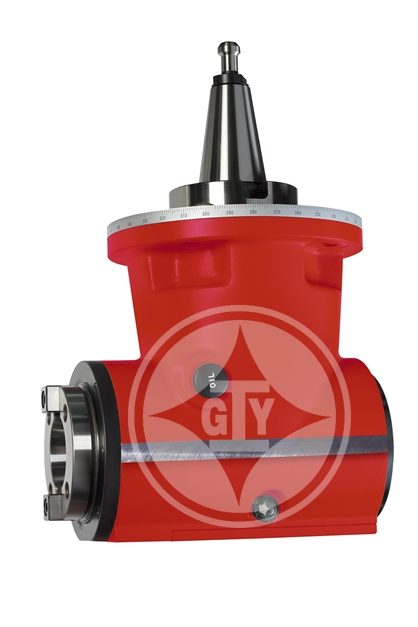

MONGTEC PRECISION INC.

Product Description :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

YIH KUAN ENT CO., LTD.

Product Description :

1. IK milling heads can upgrade or replacement your original machine body, milling machine or special machine.

2. Chrome quill with super precision preloaded bearing can bring the high quality cutting benifits for machine and we also offer P4 bearings for your optional.

3. Machining travel can up to 127mm (5").

4. This product offer NT30 or R8 two kind of spindle machine model for you to optional.

5. Offer table 254x1720mm、X.Y.Z travel 851x405x440mm turret milling machine body (whole body) for you to optional.

6. There are 11 models in IK Turret Milling Machine Head Series.

With ultra-precision pre-load bearings, can bring you high-quality cutting benefits, but also provide P4-class bearings for you to choose from

HAINBUCH GmbH

Product Description :

The HAINBUCH SYSTEM allows you to clamp 1,000 different workpieces and gives you everything you need for complete machining.

You need only one basic clamping device – a chuck or a stationary chuck that remains on the machine. For O.D., I.D., jaw or magnetic clamping, or clamping between centers you then use adaptations – without having to accept any compromises.

The workpiece defines the adaptation and converts your basic clamping device for the particular application. This incredible solution reduces set-up time substantially, while increasing flexibility and making it possible to easily squeeze in short-term jobs.