Theme

Digital Transformation

Green Transformation

YOKE INDUSTRIAL CORP

Product Description :

1. Size from M8 to M48 to fulfill your demand

(M8 ※ 0.3t _ M64 ※ 12t)

2. Design Factor 4:1, Working load limit could be up to 32 tons

3. Lifting point is made by forged alloy steel, quenched and tempered

4. 360 degrees rotation to avoid traditional eye bolt bending.

5. Light weight, High Performance, easily for using

Deliver with test certification to guarantee your safety

HSU PEN INTERNATIONAL PRECISION MACHINERY CO., LTD.

Product Description :

*Employs high rigidity, extra large radial and axial bearing.

*For models over 255, the tilting axis employs the latest full circumference brake, featuring even braking force without runout. Maximum clamping area, higher clamping force, no vibration and no braking delay is required. High torque combined with compact, rigid and enclosed structure ensure high cutting quality.

AUTOGRIP MACHINERY CO., LTD.

Product Description :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

HAINBUCH GmbH

Product Description :

Ideal for today's high paced manufacturing environment!

Convenient, that the HAINBUCH quick change-over systems fit on all your machines. Even better, that you can change your clamping devices in a matter of minutes, thus earning money quicker and allowing you to manufacture job-oriented. And, thanks to our unique technology, you will achieve a repeatability of ≤ 0.003 mm on the interface.

However, our high-speed solutions have even more to offer: As you will experience shorter machine downtimes along with reduced processing and throughput times,

your quick change-over systems will pay off in no time. Better yet, you will not have to compromise on quality, rigidity or precision.

Select the spindle connection and the clamping device that is right for you from our extensive assortment. We can even accommodate you if you are already using clamping devices made by other manufacturers. We will simply adapt them to our interface.

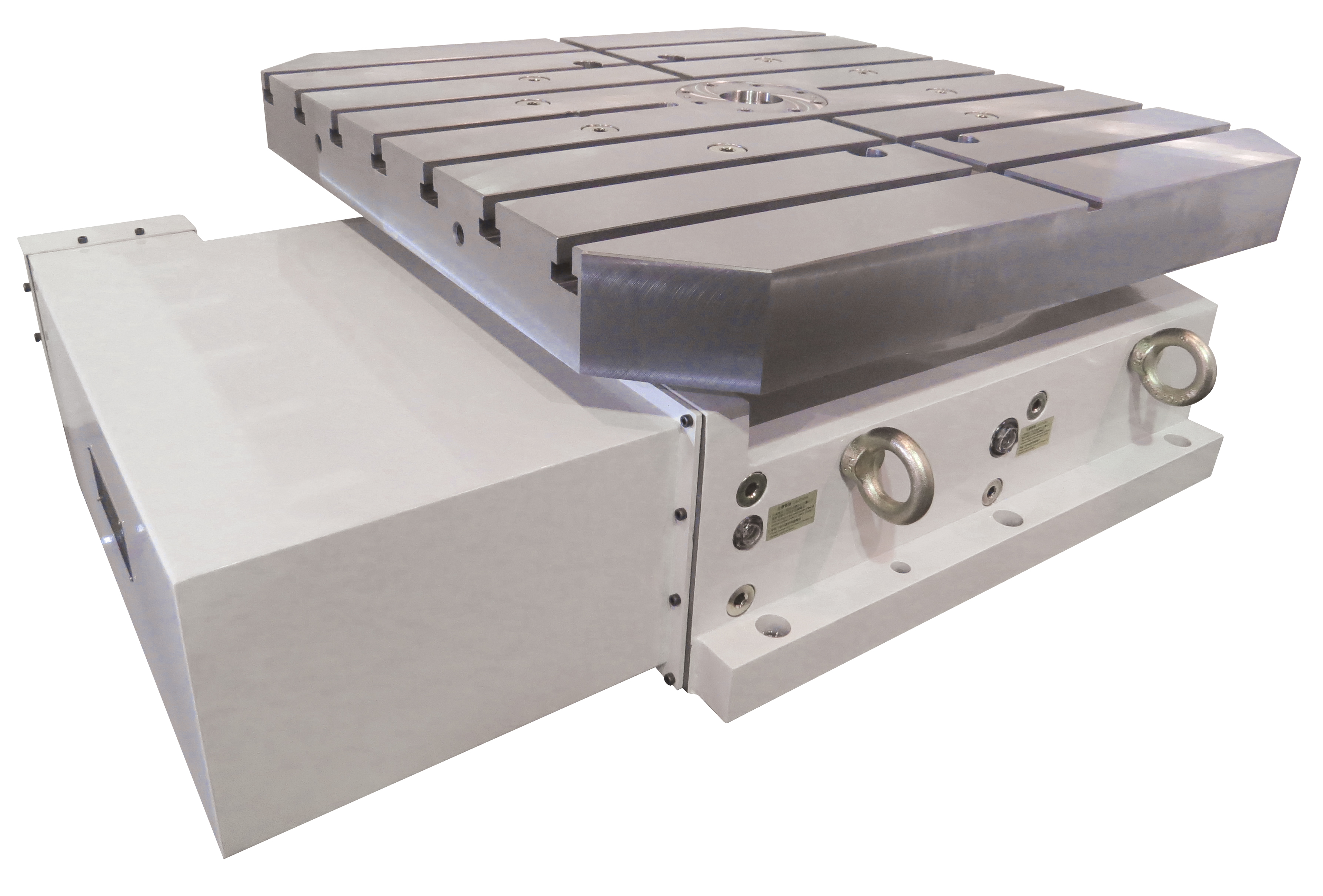

GSA TECHNOLOGY CO., LTD.

Product Description :

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。

Tokai Spring industries, Inc.

Product Description :

Tokai spring is committed to manufacturing small-lot and custom-made spring orders because we believe that there are customers who need highly specialized, high quality spring products. Tokai spring’s mission is satisfying or even exceeding our customer’s requirements.

FUTECH PRECISION CO.,LTD.

Product Description :

Ultra-short, high speed, light weight.

Designed with a detection device, which can be equipped with an inductive proximity switch.

Easy to adjust to ensure the correct operation of the hydraulic cylinder.

Built-in safty self-locking valve and pressure relief valve.

Dual-purpose type, can be installed by the front and rear ends.

The oil pipe must be connected to the oil pressure tank separately to avoid back pressure.

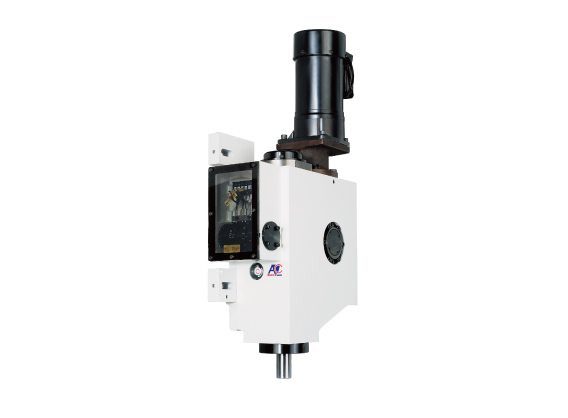

HOLD WELL INDUSTRIAL CO., LTD.

Product Description :

● With a U-Drive unit commanding the feed control of the tool slide and the tool placement even during rotation, it is made to o er the solution to a series of processes such as threading, conical threading, grooves, slots, curve surface machining and other complex pro

les. It makes it possible to

do turning operations on all machining centers.

● It is designed to be used on automatic tool changers to maximize the working e

ciency.

● Modular tool-holder slide with interchangeable design permits the various tool applications and machining.

● It is specially designed with two counter-weights for automatic balancing, which move opposite to the slide to e ectively eliminate oscillations.