Theme

Digital Transformation

Green Transformation

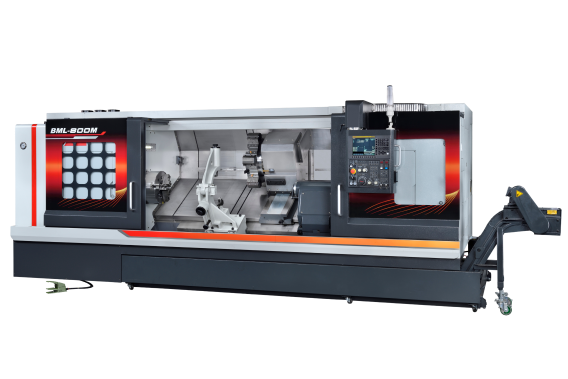

YIDA PRECISION MACHINERY CO., LTD.

Product Description :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro spares no effort to develop intelligent manufacturing; fully demonstrating its determination from Industry 3.0 to 4.0, Campro not only has successfully launched CAMPRO IIoT system in line with Industry 4.0 elements in 2016, but also developed its CAMPRO Smart FMS system in 2018. Through flexible manufacturing system, digital control and automated NC program and machine assignment that it can quickly react in case of changes and respond to market demand. In addition, CAMPRO also develops, CAMPRO TOOLING MANAGEMENT SYSTEM, a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. In some cases, the fact is increasing automation can improve worker safety and the flexible automation processing is sufficient enough to cope with complex manufacturing processes.

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

The WTS series combine with double turret, double spindle and double Y axis. Both of 16-station power turrets are available to be equipped of BMT-55 tooling system. The WTS has E-axis shifting function, it allows the sub spindle to move up and down to provide independent working area.

The WTS-52Y2M provide ∅51mm maximum bar feeding dia. and it can install fixed tailstock above the sub spindle when using collet, it allows to keep the longer workpiece dynamic balance with the main spindle and improves precision during machining. The WTS-65Y2M bar capacity up to ∅65mm, the A-6 spindle nose can install larger size chuck and the spindle motor upgrade to higher torque and bigger power.

MING YANG MACHINERY CO., LTD.

Product Description :

This heavy duty multi-tasking turning center is an advanced and economical solution designed to process precision complex parts with fast cycle times.

Power & Versatility: It has Double Spindles, a BMT 12 station turret and 4 gang tools for economical machining. Coupled with superimposed cutting it’s a powerful solution for precision complex workpieces with extremely fast cycle times.

Front Machining: BMT 45, 12 Stations, Up to 24 Tools, 7.5/11 kW Spindle Power, 55 mm Through Hole

Back Machining: GT42: 4 x 20 mm ID Tools, GT52: 4 x 16 mm ID Tools, Or 3x 20 mm ID Tools, Or 3x 25 mm ID Tools

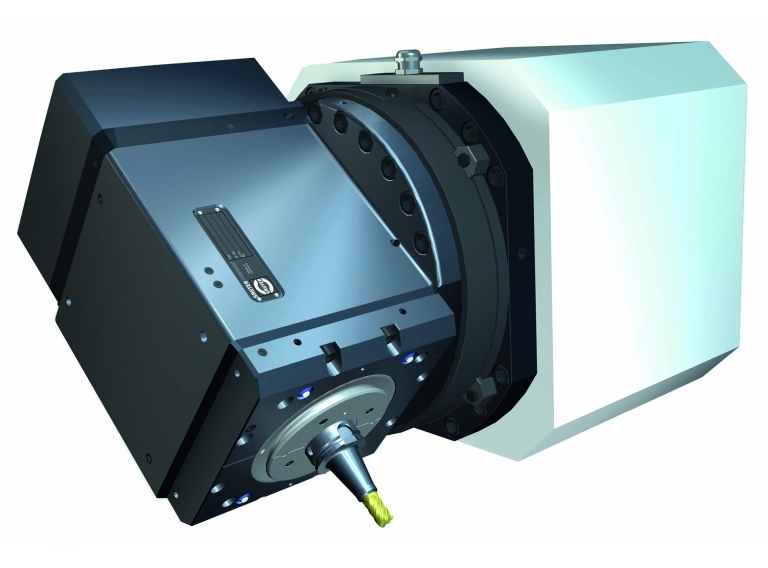

GPM CO.,LTD.

Product Description :

1. Suitable for complex processing machine

2. 2 sets of 48-teeth hirth coupling

3. Modular Shank system(HSK,Capto,KM)

4. High clamping force with Hirth coupling inside (Max 7200Nm)

5. Compact design - Equipped with permanent-magnet motor

6. internal coolant: 80bar

7. Max torque: 120 Nm

8. Max speed : 12,000 rpm

9. Quick Connector Design

CHIAH CHYUN MACHINERY CO., LTD.

Product Description :

■No matter what operation – turning, milling, drilling, tapping, cutting, side turning and back machining, the

CB series does it all in one operation.

■Sliding head without a guide bush design provide faster setups, lesser remnants, and more cost reduction.

■The CB series provide multiple tooling systems is suitable for versatile cutting applications. On the front side

tooling system, user can set with 4+3 live tools, 6 O.D. tools and 5 I.D. tools. Moreover, on the back milling

system, user can set 4 live tools. The maximum tool speed is 6000 rpm. User can install O.D. and I.D. tools

on the back milling system.

■The sub-spindle head moves on the precision roller type linear ways with extra-large span design for

outstanding stability and positioning accuracy.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

PJ-30MT is a fixed volume complex system. Controlled by the modular PCB board, provided the abnormal message notification of the system effectively. Suitable for using the fixed volume machines, such as CNC lathes, machine centers. This system integrates great advice from our countless loyal customers, and also LIS gain experiences in a broad of customers’ base developed a high-pressure coolant system for most industries when customers use the PJ system, it is more humane, easy to install, operate and maintain. Without a doubt, this is just a product of LIS which combine the suggestion from multiple parties.

VAST MILLTURN TECHNOLOGIES CO., LTD.

Product Description :

T series turning centers are designed from structure to entire operation flexibility; extreme rigidity provides the best stability for long and large diameter work-pieces. With the various spindle choices, make it possible for the best powerful performance for many types of job.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

Product Description :

.Turning & Milling in one set-up

.Y-axis travel 260 mm (10.2")

.Max. turning dimension Ø500 x 1075 mm

.Turning spindle 4200 rpm / 15 KW with 8” chuck for Vmt-X200, or 3500 rpm / 22 kW with 10” chuck for Vmt-X260

.Milling spindle 12000 rpm / 22 kW

.with HSK-T63 / A63 tooling

.ATC-40 tools

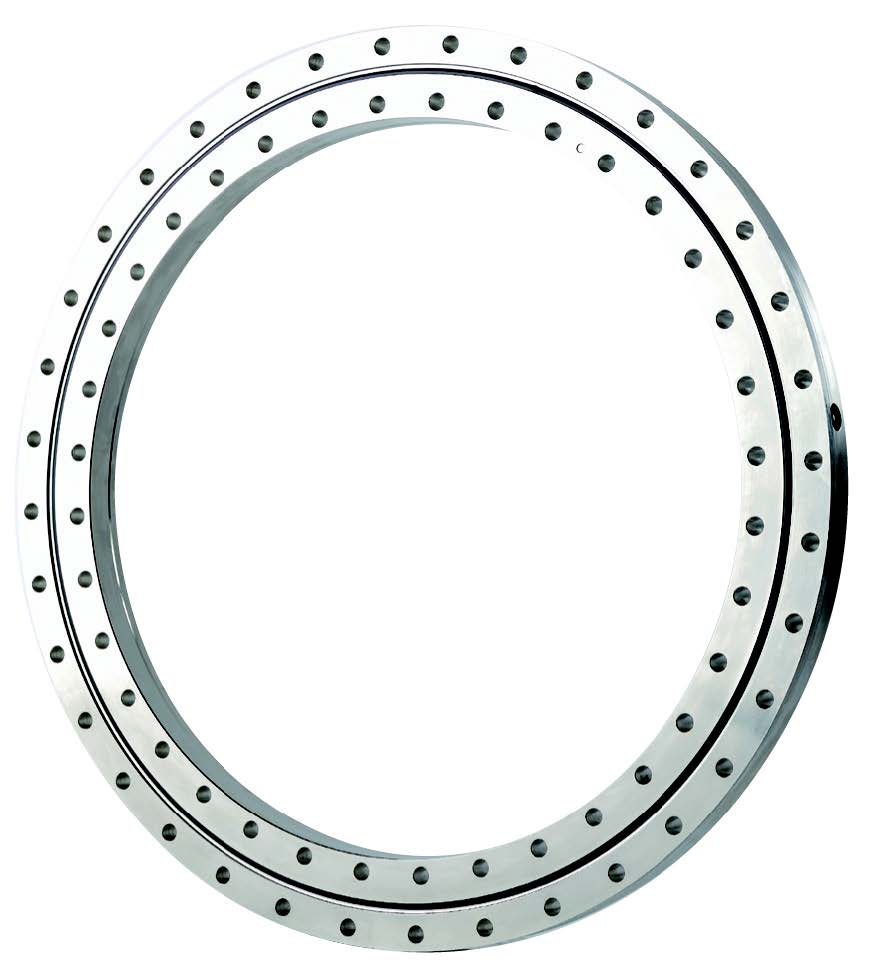

KCW ETERNAL ENTERPRISE CO., LTD.

Product Description :

The Rollix precision slewing ring series is specially designed to meet the precision needs of customers.

High precision, high rigidity, low torque and smooth rotation

The simple design combines the functions of high load-bearing, rotation and locking holes.

Mass-produced pre-load structure with highly stable precision and quality

Convenient and fast design and installation, reducing matching components

We have planned inventories at Taiwan and abroad factory to speed up the development of prototypes.