Theme

Digital Transformation

Green Transformation

RINGTECH INSTRUMENTS CO., LTD.

Product Description :

IFP vacuum cleaning machine can effectively clean any size and structure of complex metal products, great for either large or small amount of cleaning, it is also the best vacuum cleaning machine available for environmental protection and energy-saving! The cleaning cycle is carried out in a complete vacuum environment that the working environment is clean and odourless. During operation, the user can select different options from spray, rotate, ultrasonic, rinse...etc. based on the workpiece. With the cutting edge iFP cleaning technology, overcoming difficult cleaning situations such as cleaning blind holes, slits can be effortless. After cleaning, the chips and residual cutting oil will be separated from the cleaned workpiece, the chips are fully dried and can be collected from the filter; the residual cutting oil will also be separated from water and could be recycled and reused.

Facing the new industry trend and the new future, IFP cleaning machine is your best cleaning choice!

FACTORY AUTOMATION TECHNOLOGY CO. ,LTD

Product Description :

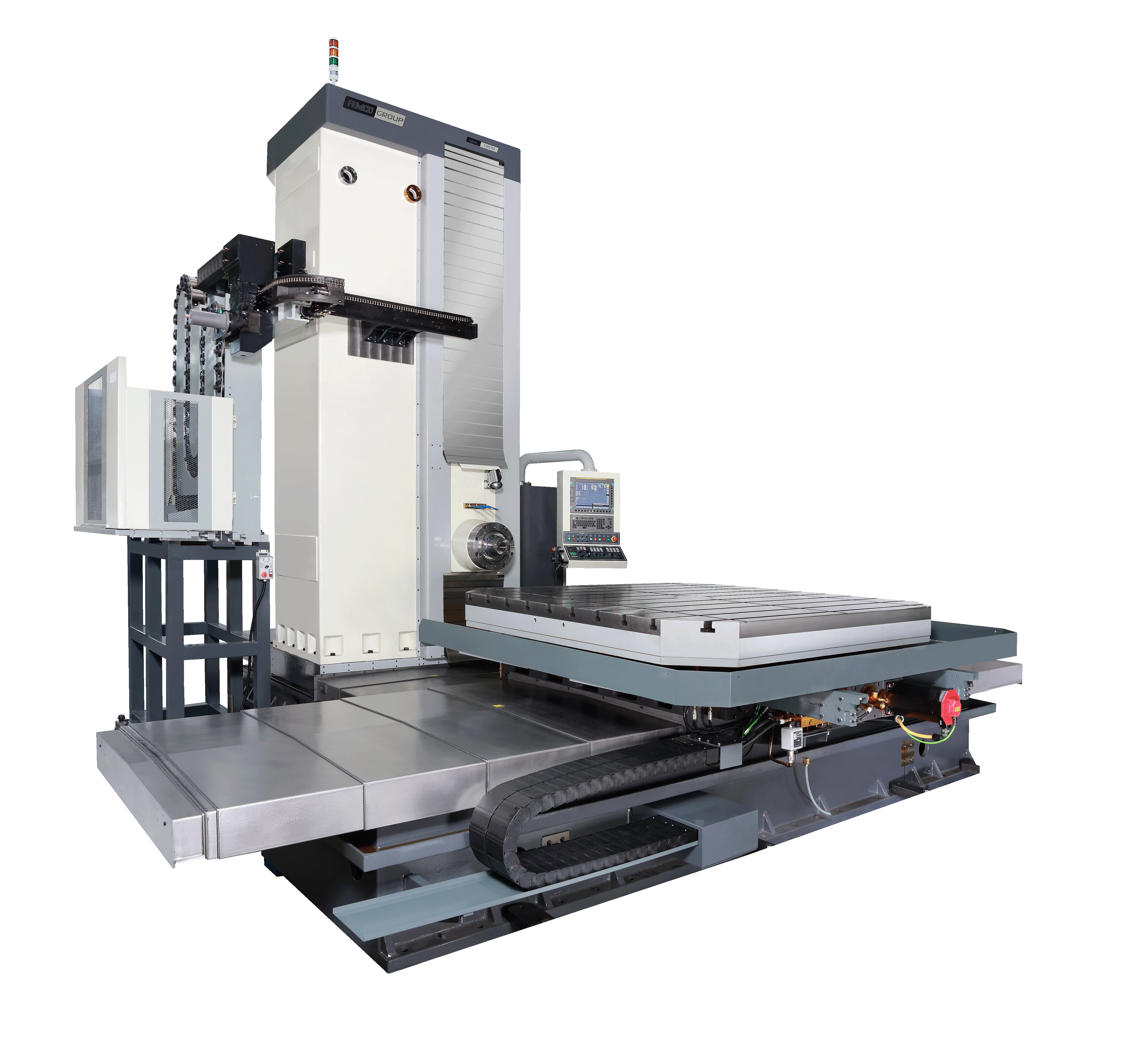

CNC Horizontal Boring & Milling Machine

BMC-135TN Features

135 mm Spindle Diameter

Moving column construction

T Type Construction Base

➣Optional X/Y/Z axis travel, flexible for various machining requirements.

➣BMC-135TN can perform extreme precision machining, powerful milling and drilling processes among similar machines in the market.

This machines can be individually tailored to meet the costumer's requirements by choosing from comprehensive options and equipment.

➣Travel

Table cross travel (X): 3000/4000(option) mm

Head stock travel (Y): 2500/3000(option) mm

Table longitudinal travel (Z) : 1500/2000(option) mm

➣Table

Table size: 2200 x 2200 mm

Table load: 15000 kg

➣Spindle

Spindle Stroke (W): 800mm

Spindle Diameter: 135mm

Spindle Motor(continuous/30 mins) :30 / 37 kW

Spindle Speed range low : 30 / 37 kW

Spindle Speed range high : 579- 3000rpm

➣Machine dimension

Height: 5080/5525 mm

Floor space(W×L×H):7200 x 7500 / 8200 x 8000 mm

Machine Weight: 33000/34000 kg

KTR TAIWAN LTD.

Product Description :

ROTEX® torsional flexible couplings are characterized by small dimensions, low weight and low mass moments of inertia yet transmit high torques. Running quality and service life of the coupling are improved by accurate all-over machining. Their application is ideal for transmitting torque while damping torsional vibrations and absorbing shocks produced by the uneven operation of certain prime movers.

ROTEX® torsional flexible couplings are equipped with the new temperature resistant T-PUR® spider which is available in three different degrees of Shore hardness.

CIN EY DIAMOND WHEEL COMPANY

Product Description :

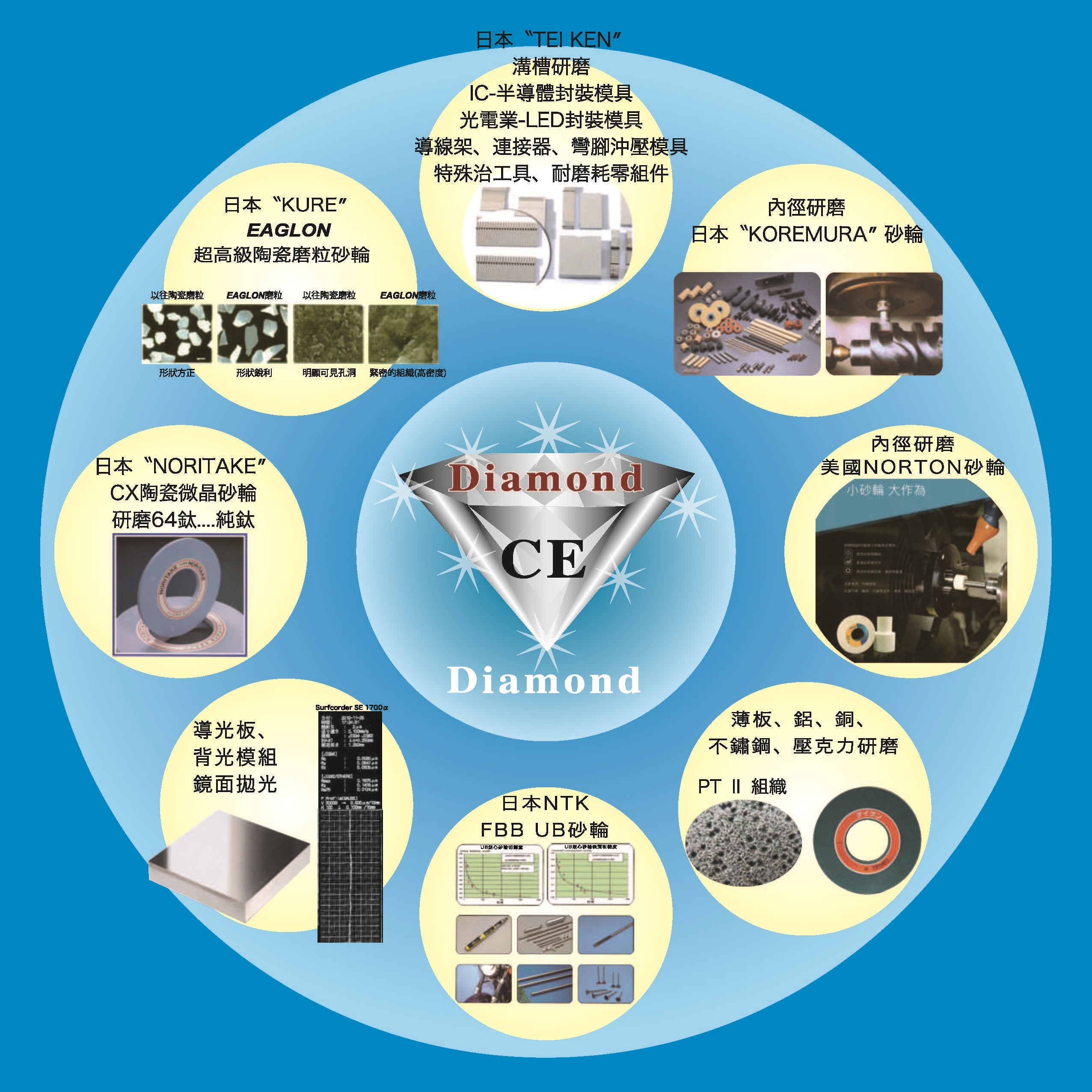

Cin Ey Diamond Co., Ltd. is a company providing professional consulting, distribution, and customization services for grinding wheels. It distributes products from Norton, the world's largest grinding wheel manufacturer (USA), as well as renowned Japanese grinding wheel brands such as Kure, Noritake, Teiken, ALMT, and NTK. With the support of the world's most advanced grinding wheel manufacturers, Cin Ey assists SMEs in industrial transformation and process improvement for industries such as linear guideways, ball screws, bearings, gears, collets, tool holders, cutting tools, and machine tools.

Cin Ey has established a professional grinding consultation center. Leveraging over 30 years of expertise and technology in grinding wheels, it can recommend the most suitable grinding wheel brands to customers and assist them in improving quality and efficiency in the grinding process. It provides professional and accurate responses and technical support that customers cannot obtain from hardware stores. Whether it's conventional grinding wheels, diamond tools, or grinding consumables, it can tailor the most suitable grinding tools for customers.

Cin Ey's business scope includes: diamond/CBN grinding wheels, diamond dressing tools, files/grinding rods, pneumatic tools/accessories, wear-resistant consumables, professional grinding consultation, shank grinding wheels, grinding and shaping tools, polycrystalline tools, stone saw blades, and general distributor of KINIK.

HC FENG CO., LTD.

Product Description :

The combination of centrifugal device and magnetic separator is perfect for processing water-and oil-based cutting fluids and sludge containing magnetic dusts and shavings. The shaving removal is quick and effective, which saves a lot of time waiting and minimizes the costs to replace consumables.

ACCUTEX TECHNOLOGIES CO., LTD.

Product Description :

AP series casting has compound table design by Y axis column moving. The center of gravity is always located between 2 linear guideways of X axis table. X and Y axes are independent without accumulation error for less deformation by FEA (Finite Element Analysis). Improved maximum loading weight is up to 1000kgs. The Bi-repeatability is less than 2.5μm after 5 times

laser calibration.

TAIWAN FANUC CORPORATION

Product Description :

Lathe chips entanglement has always been the biggest subject of automation.

Entanglement can cause problems such as suspension, failure, and workpiece defects on the machine.

The servo learning oscillation function can effectively solve the chips entanglement problem, minimize the chips and realize the realm of automation.