Theme

Digital Transformation

Green Transformation

MATRIX PRECISION CO., LTD.

Product Description :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter.

The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

YANMECH Industrial Co., Ltd.

Product Description :

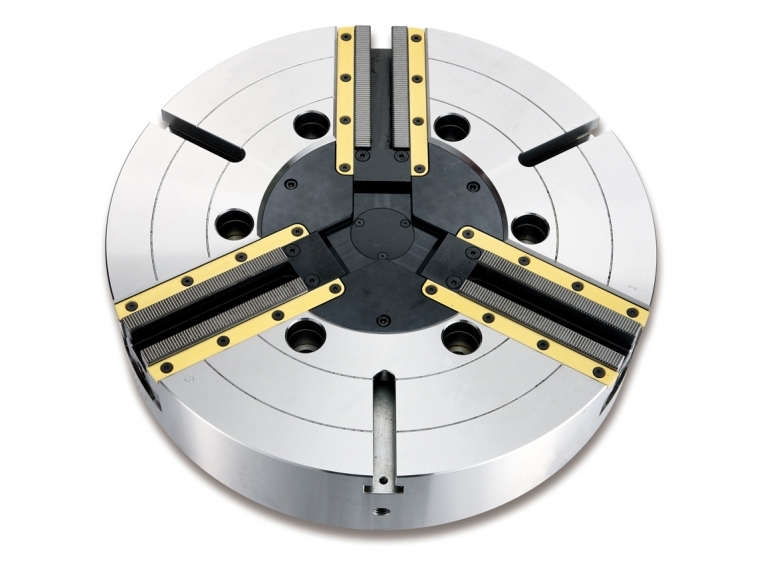

【A Series:】

1. The jaw can be individually operated, and irregularly shaped workpieces can be clamped.

2. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

【D Series:】

1. Install side strips and chips cover sealed base jaw to prevent chips and coolant ingress.

2. Adapter Plates can be selected.

3. The base jaw is lower than the body surface and can be used for multipurpose.

4. Alternative spindle adaptors:

ASA or DIN adaptors can be supplied as requested.

Fulson Industrial Co., Ltd

Product Description :

This high precision surface and form grinder has been specially developed and improved in recent years.

The tool cabinet in machine base is specially designed for operator’s convenience (618m).

The interlock between electrical cabinet door and power supply is established to ensure safe operation.

The maximum distance from table surface to spindle centerline is 18" (450mm) which provides more clearance for grinding.

The sping loaded type table travel stops will dampen theovertravel caused by abnormal operations (618m).

The optimum span of double V crossfeed guideways is designedbased on bending moment, kinematics supporting force.

All essential castings are mode of high grade of meehanite castiron that is stress relieved through annealing to eliminateinternal stress.

With the greatest stiffness and stability of the castings, this machine is suitable for both precision surface grinding and formgrinding .

This grinder is offered with one-full-year limited warranty formechanical and electrical parts .

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON, pioneer of the first capacitive two-hand control system, ensure the highest safety category according to (Cat. 4) and PL e (DIN EN ISO 13849-1). The capacitive "safeCAP" two-hand control allows heavy machinery and systems in automated production plants, such as presses and punches, to be controlled safely and without pressure.

To start the machine the user simultaneously presses two capacitive buttons which are connected to a safety relay. Incorrect or inattentive control using just one hand or with another part of the body is detected by the system and the machine is not started.

CAPTRON supplies the safeCAP two-hand control with additional safety elements such as the Protector or the control desk for tabletop installation. These combinations enhance protection and are certified to DIN EN 574. The dynamically switching SENSORswitches detect interference factors such as dirt, dust or foreign bodies. The switches can be actuated using disposable or work gloves, however.

PINNACLE MACHINE TOOL CO., LTD.

Product Description :

嵩富DV系列針對模具、精密零件加工需求所設計的高剛性主軸,BT50-8000轉強力直結式主軸、搭配高低檔齒輪箱(全齒式-無皮帶); 可粗切、精修一次完成。亦可選擇高速BT50內藏主軸或BT40直結式主軸,以符合不同的加工需求。<br />

DV系列X軸1700~4000mm,Z軸900~1100mm,門寬1400~2100mm,全採用高級米漢納鑄鐵、並可選擇90度頭 /延伸頭 / 角度頭 / 萬能頭 / BC頭 / 5面頭 / 5軸頭、自動立臥換刀、自動換頭倉,更有彈性應用、減少工序、提高率能。<br />

HYDEX MACHINERY INDUSTRIAL CO., LTD.

Product Description :

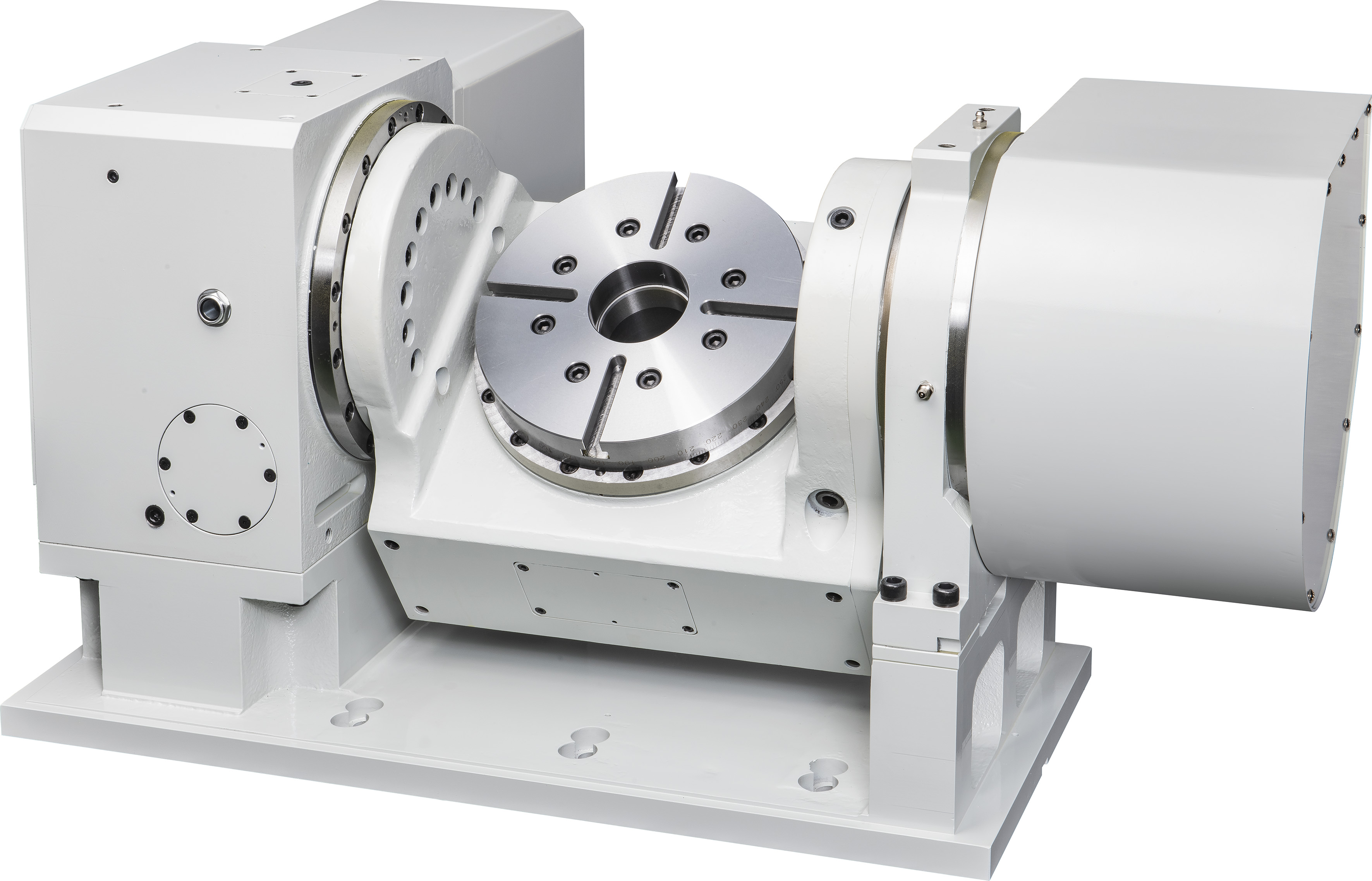

The roller cam consists of an input cam shaft and a roller turret.

The roller cam is designed with rolling contact, featuring high rigidity, high speed, and outstanding durability.

Engagement between the roller and cam are preloaded to fully eliminate backlash that enables the roller and cam to exhibit their ultra-high precision feature.

Besides, with rolling contact to transmit kinetic energy, energy consumption during drive can be dramatically reduced. This enables the roller cam to achieve over 90% of transmission efficiency.

TES ELECTRICAL ELECTRONIC CORP.

Product Description :

FEATURES :

• 10 Display Easy - to - View LCD Screen.

• Connectors for 4 Current Sensing Clamps.

• 1P2W, 1P3W, 3P3W2M, 3P3W3M & 3P4W Power Measurement.

• True RMS Sensing.

• Power KW, KVAR, KVA, PF,θ,Hz, &

Energy KWh, KVARh & KVAh Measurement.

• Phase sequency indicator function.

• Backlight display function.

• Manual Data Memory and Read (50 sets).

• Data Logging

• USB Optical Interface with three phase voltage /

current Waveform display and Harmonic analysis.

• Easy - to - use Push - Button Operation.

• Light Weight, Portable Design.

YIH KUAN ENT CO., LTD.

Product Description :

The Plano Milling Head (Gantry Milling Head) are commonly used milling machine heads such as gantry milling machines, boring milling machines, and double-head milling machines. Uses include rough milling, finishing milling, boring holes... and other processing requirements.

The left and right vertical milling heads offer excellent flexibility and adaptability. Their adjustable angles and swivel capabilities enable operators to perform angular milling, drilling, and other complex operations with ease. They are compatible with different milling machines, providing a seamless integration into existing setups or as a valuable addition to new milling machine installations.

1. IK milling heads can upgrade or replacement your existing machine body, milling machine or special machine and also it can bring more stable and high-quality machining benefits for work piece cutting.

2. It is used for mold manufacturing or precision processing.

3. The machine processing for travel is 320 mm. We also provide “No slide” format.

4. This product is used in Gantry (Plano) Milling Machine (vertical / horizontal), suitable for heavy metal cutting.

5. Plano milling head series offer accessory head for you to optional.

It will apply for multi-angle machining to upgrade efficiency and longer machining range.

6. This product of standard motor is 10HP. We also offer 12.5HP for you to optional.

7. Offer pneumatic blade locking device, bearing guide screw, pneumatic leveler for you to optional.

8. There are 10 models in IK Plano Milling Machine Head Series.