Theme

Digital Transformation

Green Transformation

MATECH INDUSTRIAL CO., LTD.

Product Description :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

TAIWAN FANUC CORPORATION

Product Description :

In the current era of high personnel costs. Are you also considering importing automation, but you are worried that the technical threshold is too high and you will not be able to operate it!

Through FANUC QSSR, you can quickly connect with the robot, and use the familiar CNC operation interface to directly operate the robot, simplify the time of getting started with the robot, and quickly introduce automated production.

Taiwan Machine Tool & Accessory Builders’ Association

Product Description :

TMBA's members can join below 10 committees by their interest:

1. Machining Center Issue committee.

2. Turning Center Issue committee.

3. Forming Machine Tool Issue committee.

4. Non-traditional Machine Tools(EDM, Laser,…,etc) Issue committee.

5. Multi-Tasking(/Integrated) Machine Tool Issue committee.

6. Grinding Machine Tool Issue committee.

7. Functional components Issue committee.

8. Raw Material and Processing Issue committee.

9. Transmission component Issue committee.

10. Accessories & Hardware Issue committee.

CHAIN HEADWAY CO., LTD

Product Description :

Fine Adjustment Face Milling Cutter | Mirror Surface Finish for Steel and Aluminum

In precision machining, the finishing cut defines the final quality. For industries like automotive and mold-making, achieving mirror-like surfaces without compromising tool life is a constant challenge. At Chain Headway, our fine-adjustment face milling cutter series is the result of years of engineering experience, offering micron-level control for consistently high-quality results.

Ultra-Precise Mirror Finishing with Micron-Level Adjustability

Chain Headway’s face milling tools feature a fine-adjustable insert seat and modular cutter head, allowing edge height control within ±1 micron. This level of accuracy achieves mirror-like surface finishes with Ra < 0.5µm across a wide range of applications. Available in diameters from 50 mm to 400 mm, this solution fits most precision CNC finishing needs.

HER BAO MACHINERY CO., LTD.

Product Description :

★ Features: Utilizes Japanese worm gear and worm wheel for high rigidity, high load capacity, high clamping force, and optimal waterproofing.

★ Applications: CNC machining centers, grinders, aerospace industry, automotive components, 3C components, mold components, non-standardized parts, etc.

YI CHANG MACHINERY CO., LTD.

Product Description :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

CLAMPTEK ENTERPRISE CO., LTD.

Product Description :

The Thread-body single acting hydraulic cylinder use imported oil seal and accessories to guarantee the quality. No oil leakage while clamping in high pressure for a long time. The volume of the thread-body single acting hydraulic cylinder is small. It can be utilized in a small space in the fixture.

This hydraulic cylinder is used to extend out, and when spring returns, but it can't be used for pulling back.

The angle degree between the cylinder and workpiece could not be larger than 10° while installing.

The bottom of the cylinder barrel needs a leakage-proof gasket.

Max. operating pressure: 250 kgf/cm²

Min. operating pressure: 20 kgf/cm²

Single acting

Usable fluid:

GT MARKETING Co., LTD.

Product Description :

Cloud Computing Mobile App

The popularization of smartphones, tablets, and 4G networks have changed the modern marketing models; to help customers take the lead in grasping market opportunities, we combine cloud computing services and tailor-made mobile native apps for iOS/Android to help companies to create all-round competition advantages, looking forward to establishing a long-term partnership with customers for win-win and common prosperity.

Enterprise Self-Platform

Plan the backend management system for customers according to their needs, and assist customers in solving the pain points in the operation process and content management, such as membership management, production line management, machine registration, web content management, App content management, etc., in an all-in-one integrated backend management system, looking forward to providing customers with the best information integration platform.

Cloud Computing Hosting Service

GTMC cooperates with leading cloud computing brands: Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), Alibaba Cloud and Chunghwa Telecom IDC. We have cloud computing services and the latest technology to provide customers with the best solutions.

Exhibition Service

Assist the organizer to manage manufacturer and visitor information, provide visitors to accurately find exhibitors and products, increase the popularities of exhibits online with the most intuitive search method and use the APP functions for visitor registrations, event calendar and booth map to help for the exhibition hosting.

3D Display Solution

Integrate 3D technology on the company marketing website and present perfect product design drawings through excellent 3D designers to help customers understand the products. In addition, it supports real-time change of product appearance according to selection requirements, completes quotations and sets product specifications, and assists to increase product sales and accelerate production.

7-LEADERS CORP.

Product Description :

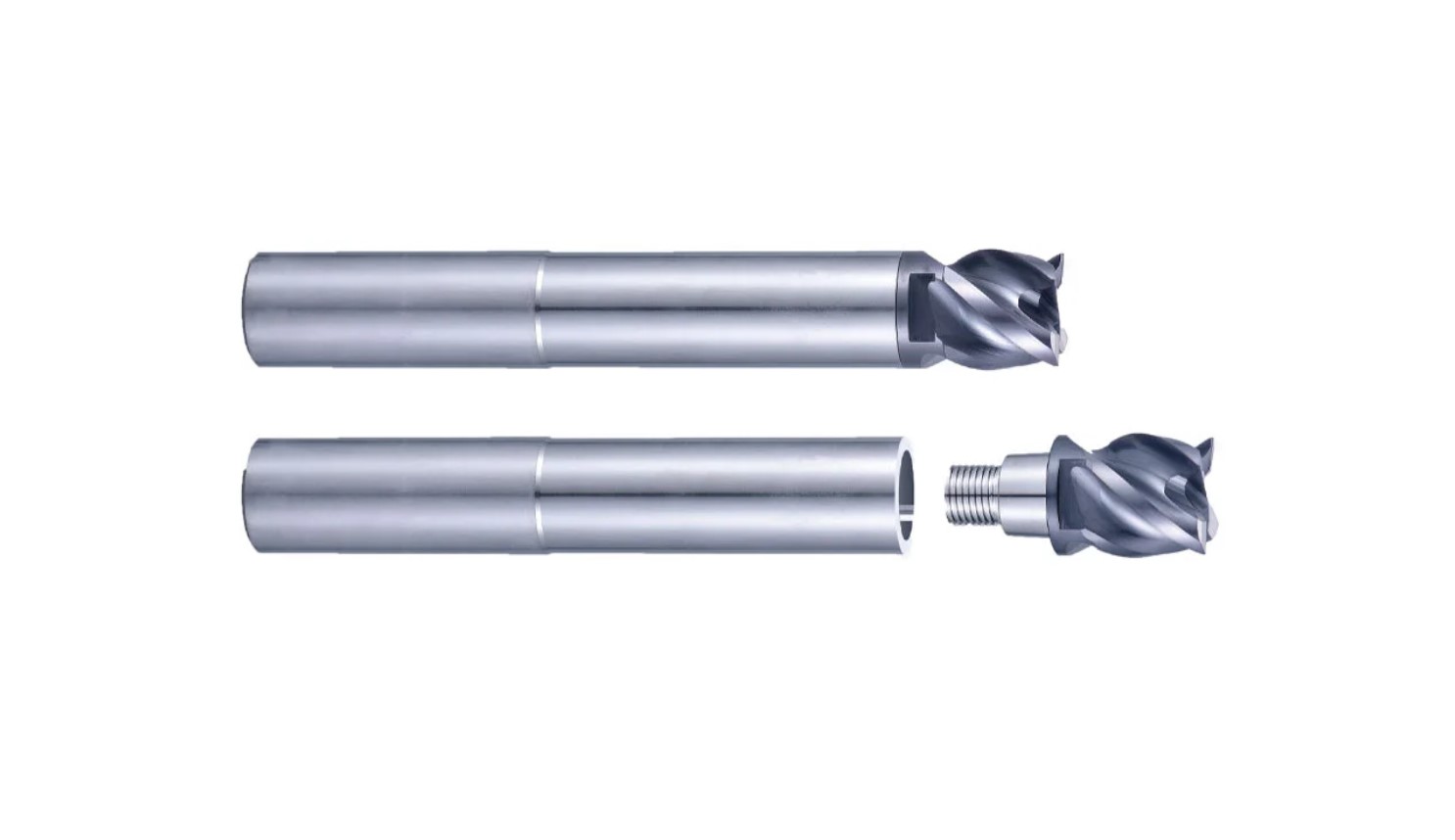

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.