Theme

Digital Transformation

Green Transformation

PEIPING PRECISION ENTERPRISE CO., LTD.

Product Description :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

We customize CNC MPG pendant encoder, comprise antistatic protection, reversed voltage protection from DC5V to 24V. Rugged model with IP67 dust-proof, oil-proof and waterproof, ergonomics design is much easier to use and smooth handling. Depending on actual needs, axis and multiplication selections can be set; function buttons, emergency stop switch, enable switch, indicator light and wire length are also optionally available.The MPG pendant handwheel is easy to install with multi-conductor cables, and can print the company logo on the manual pulse generator wheel cover. Manual pulse generator box, MPG box, Handle box MPG can choose 100 PPR pull-up, 25 PPR pull up, 100 PPR line driver, 100 PPR open circuit... etc.. Support CNC system like FUNAC, SIEMENS, MITSUBISHI, FAGOR, HEIDENHAIN, LNC, SYNTEC, GSK and other industrial CNC machines.

SAFEWAY MACHINERY INDUSTRY CORPORATION

Product Description :

Quick Zero Point Base - Riser - QLS-H

Clamping system : manual

Modular design with high repeatablity

Made of steel , full hardness and grinding for durability

Suitable for 3/4/5 axis machines.

Suitable for all safeway Rigid Vise ( RV series )

KAO FONG MACHINERY CO., LTD.

Product Description :

Optimized C-type structure of the proportion of gold design, machine rigidity and stability of good. Three-axis use the ball-type linear guideway. Achieving a perfect balance in the perspectives of promotion of precision and high rigidiy, the product is designed for the industry with high efficiency processing need. On the aspect of cutting chip with high efficiency, the performance is near perfect , the ultimate tool to enhance production efficiency and profit cration for investors. Mainly used in general precision machinery and 3C electronic parts, and automobile and locomotive industries, processing mold industry, aerospace, medical equipment industryand so on.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 810 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

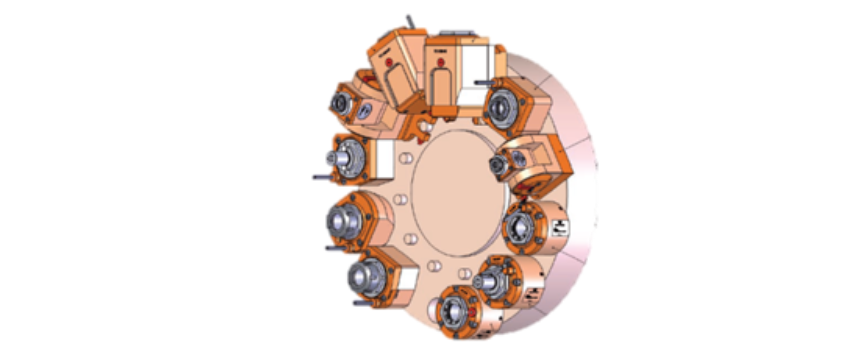

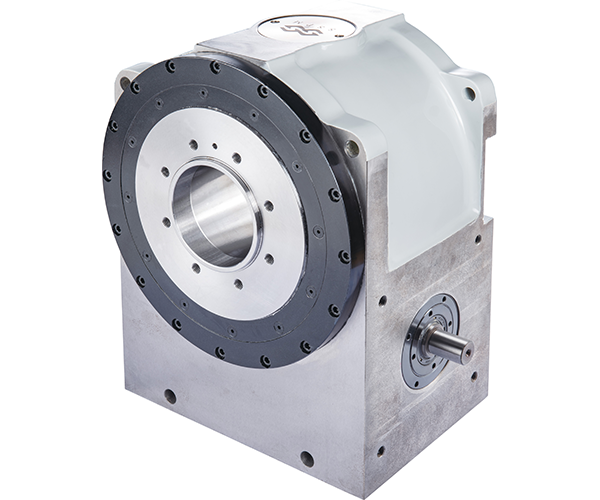

HYDEX MACHINERY INDUSTRIAL CO., LTD.

Product Description :

The roller cam consists of an input cam shaft and a roller turret.

The roller cam is designed with rolling contact, featuring high rigidity, high speed, and outstanding durability.

Engagement between the roller and cam are preloaded to fully eliminate ultra-high precision feature.

Besides, with rolling contact to transmit kinetic energy, energy consumption during drive can be dramatically reduced. This enables the roller cam to achieve over 90% of transmission efficiency.

RINGTECH INSTRUMENTS CO., LTD.

Product Description :

IFP vacuum cleaning machine can effectively clean any size and structure of complex metal products, great for either large or small amount of cleaning, it is also the best vacuum cleaning machine available for environmental protection and energy-saving! The cleaning cycle is carried out in a complete vacuum environment that the working environment is clean and odourless. During operation, the user can select different options from spray, rotate, ultrasonic, rinse...etc. based on the workpiece. With the cutting edge iFP cleaning technology, overcoming difficult cleaning situations such as cleaning blind holes, slits can be effortless. After cleaning, the chips and residual cutting oil will be separated from the cleaned workpiece, the chips are fully dried and can be collected from the filter; the residual cutting oil will also be separated from water and could be recycled and reused.

Facing the new industry trend and the new future, IFP cleaning machine is your best cleaning choice!