Theme

Digital Transformation

Green Transformation

HC FENG CO., LTD.

Product Description :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

MONGTEC PRECISION INC.

Product Description :

BODY

Re-designed main body to improve rigidity and reduce vibration. Specially treated corrosion resistant steel body.

Bearings

Angular contact preloaded ball bearings of precision class P4 / ABEC 9.

Bevel Gears

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

Torque and Speed

With Speeder 1:4:32,000 Rpm

(Standard 1:1:6000~12000Rpm)

Max Torque:160Nm

Internal Coolant

Max Pressure:70-100 bar

Benxi Tool Co., Ltd

Product Description :

The tooth edge of bi-metal band saw blade is made of high-speed steel, and the back material is spring steel. Its high red hardness and fatigue resistance fully meet the requirements of metal-cutting, which is widely used in sawing black metal materials, non-ferrous metal materials, and some non-metallic materials. It has the wide usage in metallurgy, machinery, automobiles, ships, aerospace, military and other fields.

PHD Books Co., Ltd.

Product Description :

機械雜誌的第一品牌

充滿未來性之「機械新刊」具備三點特色:

第一,「選對的主題」。機械新刊每月所挑選的文章,都是對機械產業非常重要的指標性主題,多元化的內容整合,適合讀者每月翻看,汲取新知。

第二,「用對的人」。機械新刊之主編群結合產、官、學、研各界專家菁英,提供最優值的文章和綿密的產業資訊。現在是知識經濟的時代,在知識情商方面,哪一家公司有新產品?哪一家公司有好技術?透過機械新刊廣大的客戶產品資訊,讓您在通路行銷,研發製造各方面都能領先群倫。

第三,「做對的事」。機械新刊的市場定位及聚焦策略,考量傳承與創新之間的平衡,希望雜誌內容能兼顧廣度與深度,除了持續保持專業文章的深度,更重要是與市場貼近,完全掌握市場脈動,同時加入人文的溫度。

2017年起,博士文創事業經營機械新刊,以「廣遞新知,用心規劃」為宗旨,努力建立遍及海內外的讀者群。我們計畫以台灣為中心,向海外拓及讀者群,讓所有華語專業人士,都能翻閱機械新刊,從中獲得想要的資訊。另外,我們要使刊物成為客戶最佳的行銷利器。我們充分瞭解客戶的需求,讓機械新刊成為情資收集的專業平台,展示產品的最佳舞台。機械新刊紙本刊物搭配電商規劃,讓廠商在數位時代,將有更高更長久的曝光。

機械新刊充滿前景,「選對的主題」、「用對的人」、「做對的事」,我們的團隊專業,充滿競爭力,發行人出身機械產業,親身投入用心經營。機械新刊才剛要開始發光發熱,我們有絕對的信心,成為機械雜誌的第一品牌。

YI CHANG MACHINERY CO., LTD.

Product Description :

This video features the Yi Chang Machinery model HD750 hydraulic automatic drilling machine assemble with a cam indexer combination. This combination not only achieves the rapid completion of multi-hole drilling requirements on a single workpiece but also significantly improves work efficiency, making operations much easier.

This hydraulic automatic drilling machine utilizes its efficient cam indexer , allowing you to accomplish multi-spindle drilling in a short amount of time. Whether it's for mass production or individual pieces, the machine proves to be exceptionally productive. Operating this machine is straightforward, even for beginners, and its high-efficiency design enables you to tackle work challenges with ease.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

RAISE PRECISION CO., LTD.

Product Description :

CAPTRON is an experienced measuring technology manufacturer for the industry and the market leader in fill level measurement in the field of dispensing technology. Capacitive CAPTRON probes accurately and reliable measure the fill levels of liquids, bulky goods, pastes, adhesives and chemically aggressive materials.

With the CAPselect system for level sensors, you are able to freely configure the probe of your choice depending on the application, container type and sensor properties. CAPTRON produces these with millimetre accuracy to ensure full flexibility.

There are two systems to choose from: Compact probes, in which the electronics and probe form a single unit. Probes with external amplifiers that are suitable for applications with high temperatures and pressures.

Thanks to their wear-free electronics combined with high-quality material such as stainless steel, Teflon and Peek, CAPTRON level sensors are reliable, robust and long-lasting.

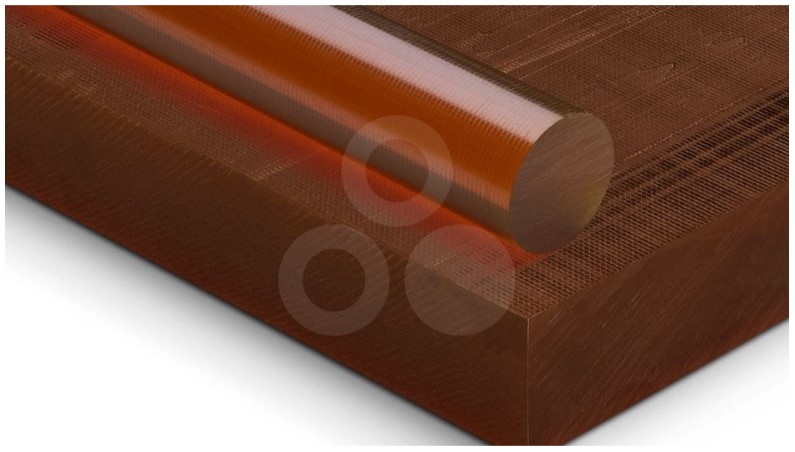

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

Product Description :

TECAPEI natural (PEI) is an unreinforced polyetherimide, suitable for contact with foods, that exhibits high mechanical strength and rigidity. The characteristic profile includes very good hydrolysis resistance, and dimensional stability, combined with a relatively high long term service temperature.

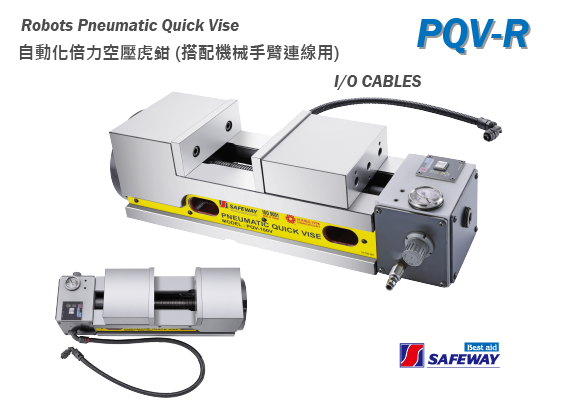

SAFEWAY MACHINERY INDUSTRY CORPORATION

Product Description :

Clamping system : Air+Mechanical power +M code

Suitable for Robot for automation

Can be connected to any machines ( I/O cable )

Built-in solenoid valve-24V

Type of socket and cables must be provided by customer

Standard cable length : 2 meters ( optional )