Theme

Digital Transformation

Green Transformation

SCN MACHINERY CO., LTD

Product Description :

深絞(深抽)成型油壓機 - SYT series<br />

<br />

Tonnage: 100 - 3000 ton<br />

Bolster Area: 800 x 700 - 4500 x 3000 mm<br />

<br />

SYT 深絞成型機 - 機身採用高張力,中鋼一級鋼板,頂座,底座,形成門型機架精加工.90°導軌八面滑合設計,滑塊上下運動,導向性好,精度好,強度高,滑合面自潤銅襯材質,導軌高週波硬化,研磨加工,永保精度不變.<br />

油壓動力系統,設計於機台後方採用管路板式集積回路設計,並附冷卻系統,效率能完全發揮,保養簡潔。<br />

油溫超過設定55度,馬達自動停止運轉,並發出警報聲,提醒操作者冷卻水異常,確保油封使用壽命<br />

配備獨立式操作控面板,吋動,下降.慢速加壓.快速上昇.等操作按鈕,前方附有緊急停止按鈕,操作容易安全,由壓力表設定出力大小、行程位置調整於微動開關設定。<br />

<br />

符合ISO9001:2015認證

GT MARKETING Co., LTD.

Product Description :

A professional video not only aims to bring a visual impact, but also can shape the audience's image for the company and the product, thereby generating more benefits.

GTMC has always introduced the most advanced shooting equipment and with the most professional and dedicated service team to assist Taiwan's small and medium-sized enterprises in the production of multimedia videos. From planning, copywriting and scripting, executive production, photography, lighting, post-production editing, 3D animation design to 2D special effects design, etc., we have recruited various professionals across fields to assist companies for different video shooting needs and styles. Creating the most insightful company image video and product introduction video combining with GTMC online marketing experiences carries out the most efficient promotions for customers.

The use of 4K high-quality video recording system combined with 3D computer animation can clearly and completely present the most complete information of companies, products, and services, crossing the distances and limitations of time and space, allowing global buyers to immerse themselves and deepen their impressions.

PROTH INDUSTRIAL CO., LTD.

Product Description :

1.10" touch panel.

2.The Y-axis(cross) and Z-axis(vertical) are driven by serve motor.

3.Use MPG in Y-axis and Z-axis.

4.Use PLC controller.

5.Flow control regulator is used in longitudinal way for using well.

6.Auto down feed system includes auto dresser and compensation.

7.Machinable content : surface, criss-cross, plunge, form pitch.

LEEKA INDUSTRIAL CO., LTD.

Product Description :

We produce draw latches with different kinds of size and specifications.

The material uses stainless steel and Iron.

Color: black powder coated or bright chrome.

The installation depends on different type of latches: horizontal or vertical installation and can be used with padlocks.

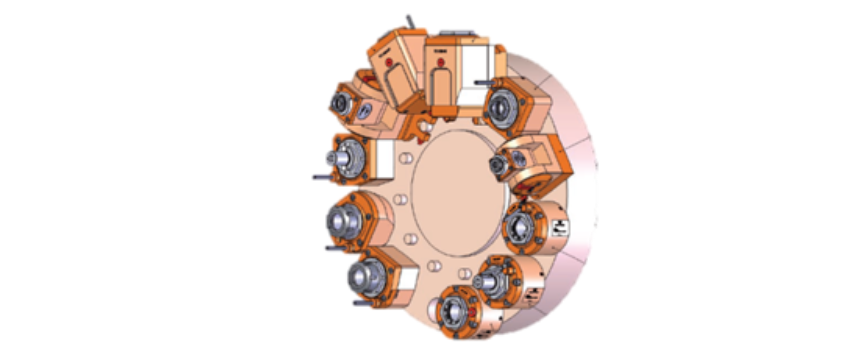

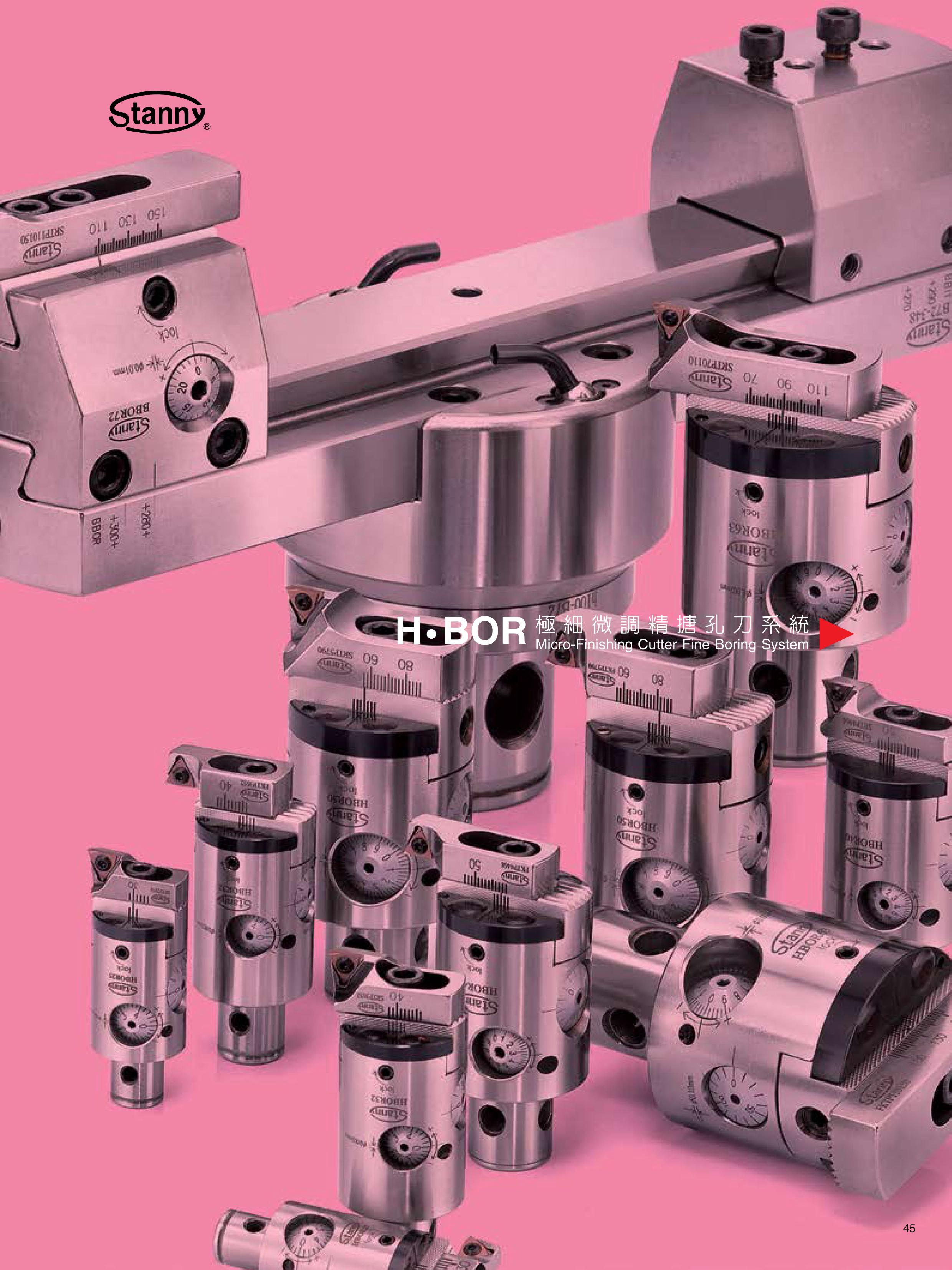

SHIN-YAIN INDUSTRIAL CO., LTD.

Product Description :

The structure design provides compensation for the axial inaccuracy when tapping, improving the thread surface roughness.

The tap use life is increased by at least 2 times compared to traditional tapping system.

Quick change modular design: tap holder body with adapter is modular design, lowering purchased cost.

Coolant through is available.

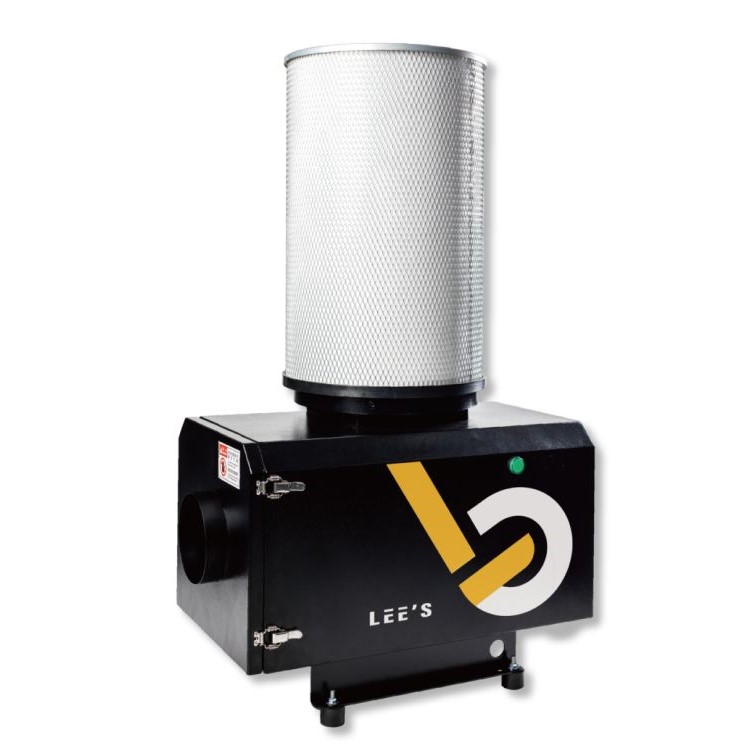

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.