Theme

Digital Transformation

Green Transformation

HOLDING ELECTRIC CO., LTD.

Product Description :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.

DAH LIH MACHINERY INDUSTRY CO., LTD.

Product Description :

龍門型結構,高速加工極穩定。<br />

12,000 / 15,000 rpm高速直結式主軸。<br />

X, Y, Z軸全配置滾柱型線軌。<br />

X, Y, Z軸快速進給率30米/分。<br />

獨創主軸熱補償功能。<br />

立柱結構左右對稱,為最佳熱平衡設計。<br />

X軸獨立於床台上,Y軸獨立於立柱上,無重疊之負荷。<br />

工作台全行程支撐無懸垂,偏移問題,確保最佳加工精度。<br />

三軸滑軌配置線性滑軌,形成穩定順暢,並兼顧高速加工之需求。<br />

衝錘式主軸頭、開頂式護罩。<br />

滾珠螺桿中空冷卻。

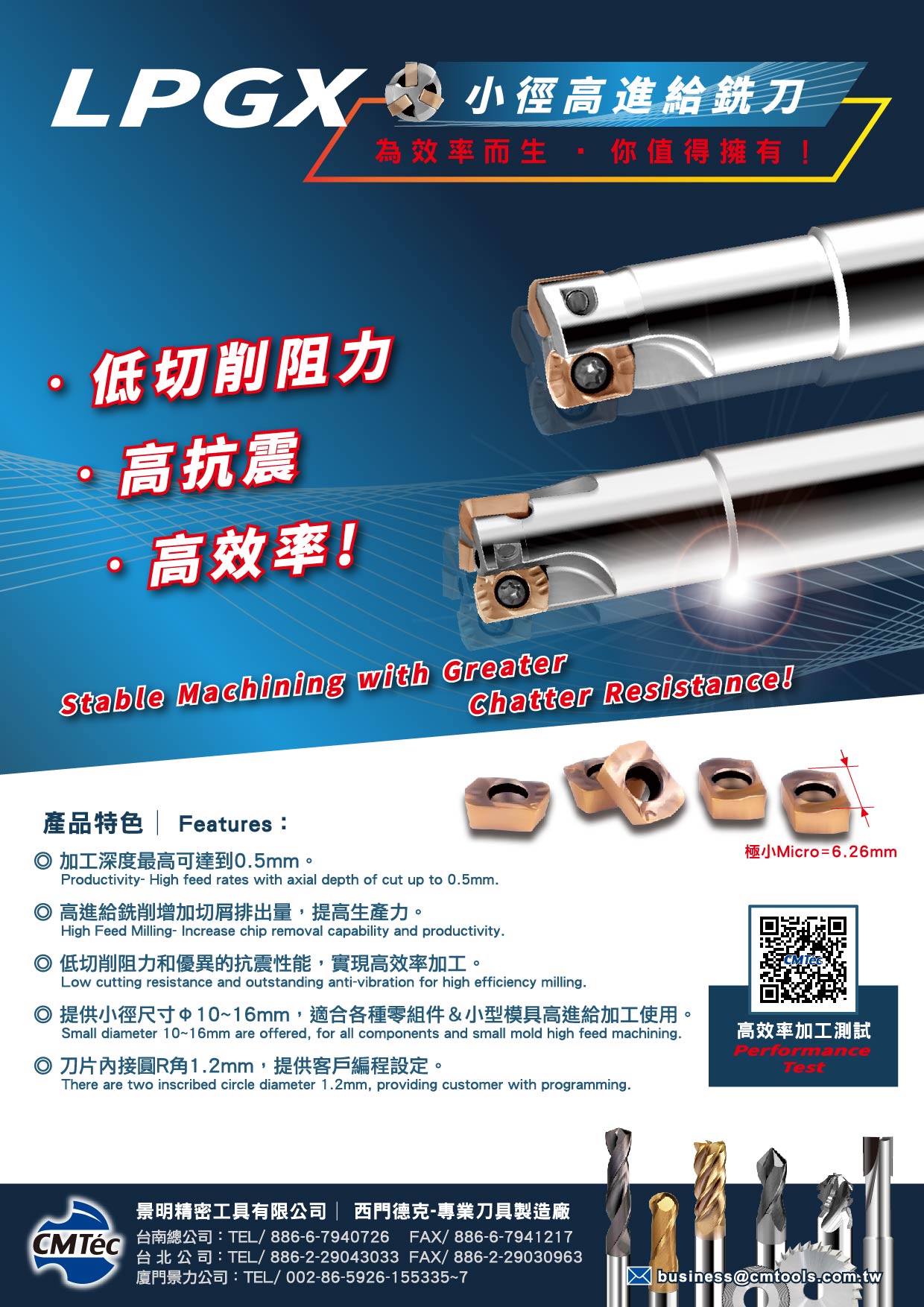

CHIN MING PRECISION TOOLS CO., LTD.

Product Description :

★ Productivity- High feed rates with axial depth of cut up to 0.5mm.

★ High Feed Milling- Increase chip removal capability and productivity.

★ Low cutting resistance and outstanding anti-vibration for high efficiency milling.

★ diameter 10~16mm are offered, for all components and small mold high feed machining.

★ There are two inscribed circle diameter 1.2mm, providing customer with programming.

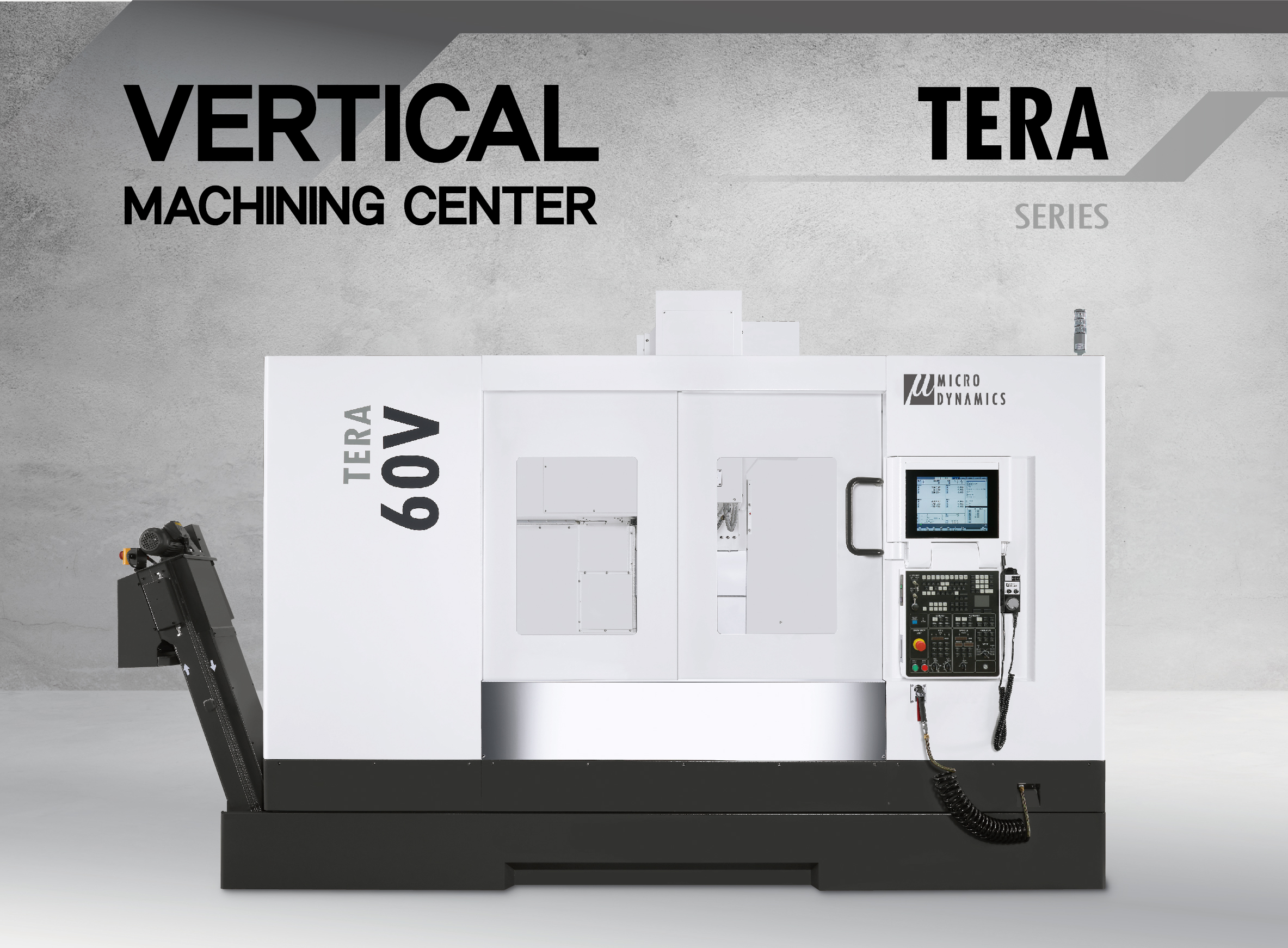

INNOSERV FA INC. TAICHUNG BRANCH

Product Description :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

E-TECH MACHINERY INC.

Product Description :

e-tech Machinery Inc. introduces EGP, EGA & EGP-A series of CNC cylindrical grinders with superb grinding capabilities and choice of control options. The customers' requirements can be met with a choice of many machine options, such as a touch probe, automatic sizing device, or swing down ID grinding attachment. The complete product line offers a wide range of between center distances and center heights in both plunge and angular wheelhead designs. Automation and turnkey solutions can be offered optional equipment.

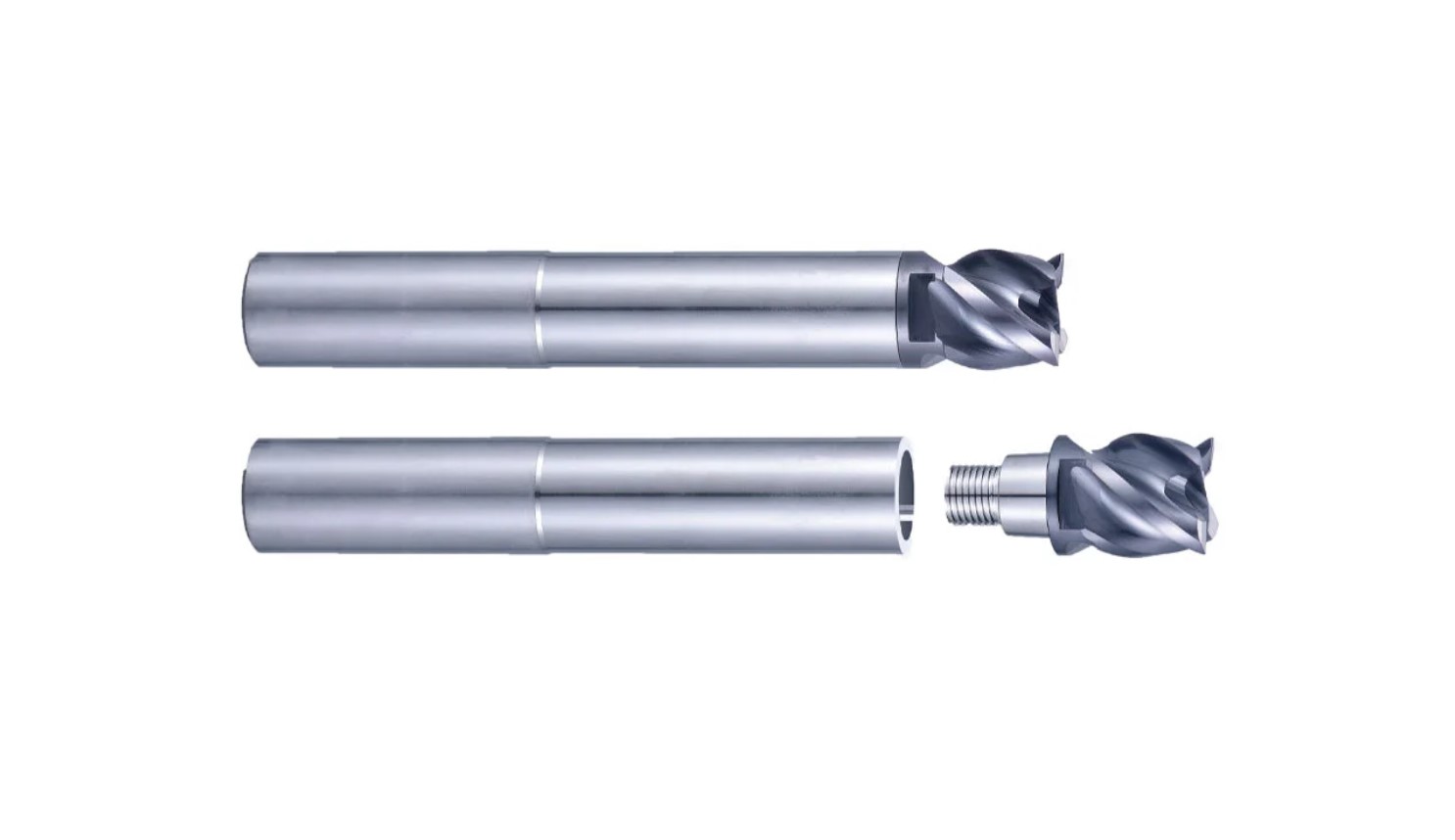

7-LEADERS CORP.

Product Description :

Multipurpose End Mills with Corner Radius- 4 Flutes

Using UMG carbide material enable to enhance lubrication and wear resistance.

Effectively decrease the vibration by various helix geometry and unequal flutes designs.

Big chip breaker is designed to reach high removal rate for various work materials.

Cutting edge with corner radius design and nano multilayer coating AlCrN are suitable for carbon steel, alloy steel and stainless steel with impurities and sticky materials.

Suitable for various kinds of work materials from the end of roughing to finishing.