Theme

Digital Transformation

Green Transformation

MING YANG MACHINERY CO., LTD.

Product Description :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

PRECISION MOTION INDUSTRIES, INC.

Product Description :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

CHIEN CHENS MACHINERY CO., LTD.

Product Description :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

R PLUS TECHNOLOGY CO., LTD

Product Description :

1. Automatic detection cutting processing work. Prevent cutting process failure or missing.

2.After cutting the part surface smooth with better quality.Good quailty.High stability.

3.Best cutting state feedbacck signal function. Can be connected to the manipulator or robots. The installation is more convenient.Widely versatility.

4.Automatic testing possesses function. While system upfrades to industrial 4.0, ours products still can be used. Reducing the risk of investment and waste

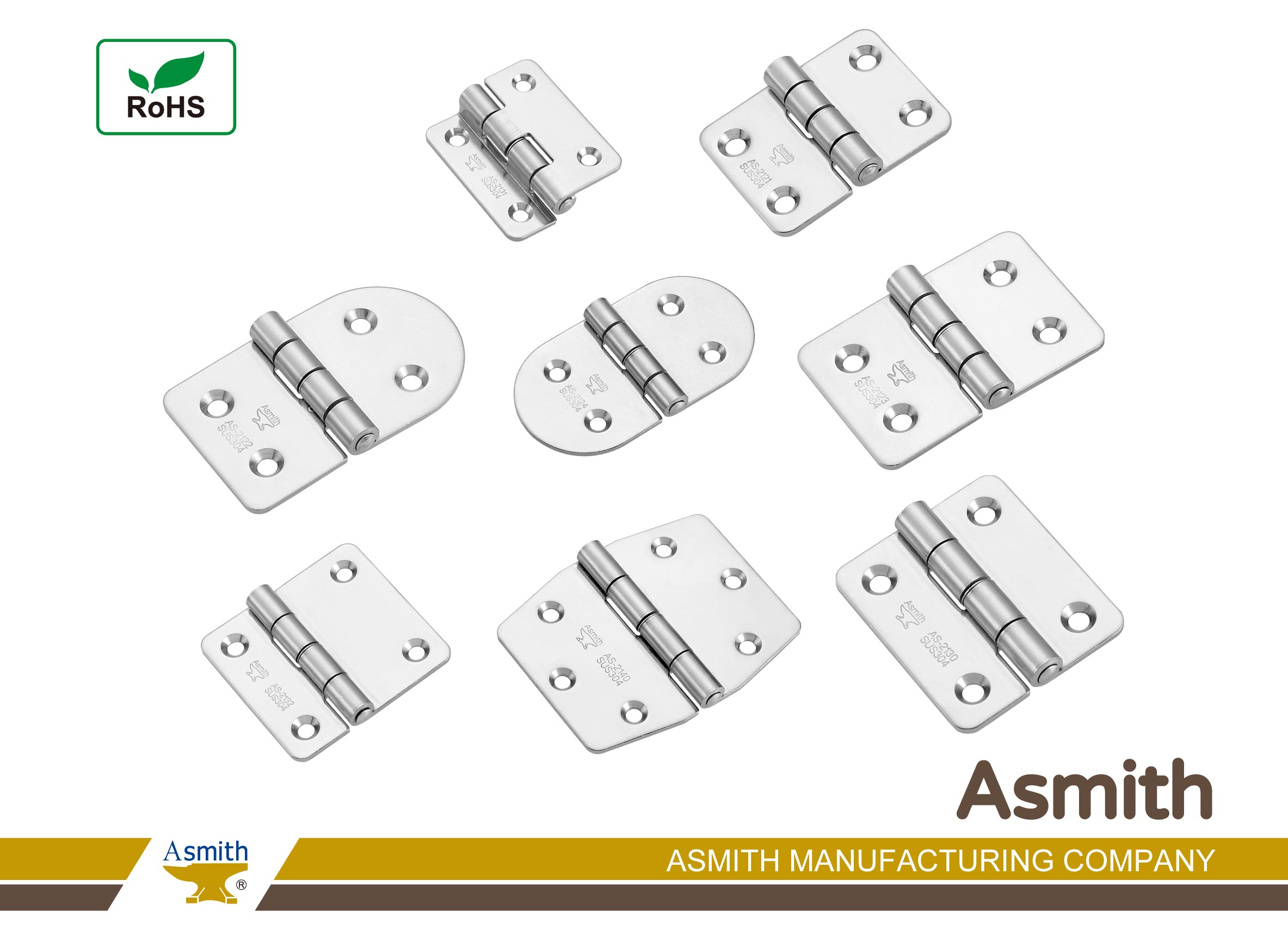

ASMITH MANUFACTURING COMPANY

Product Description :

AS-21 Series

Micro-damping friction butt hinge allows the door panel to be fixed at any position when opened left or right. Features stepless self-positioning control. Counterbore hole design, suitable for countersunk screws.

More info:https://www.asmith.com.tw/en/products/Hinge/Butt/AS-21

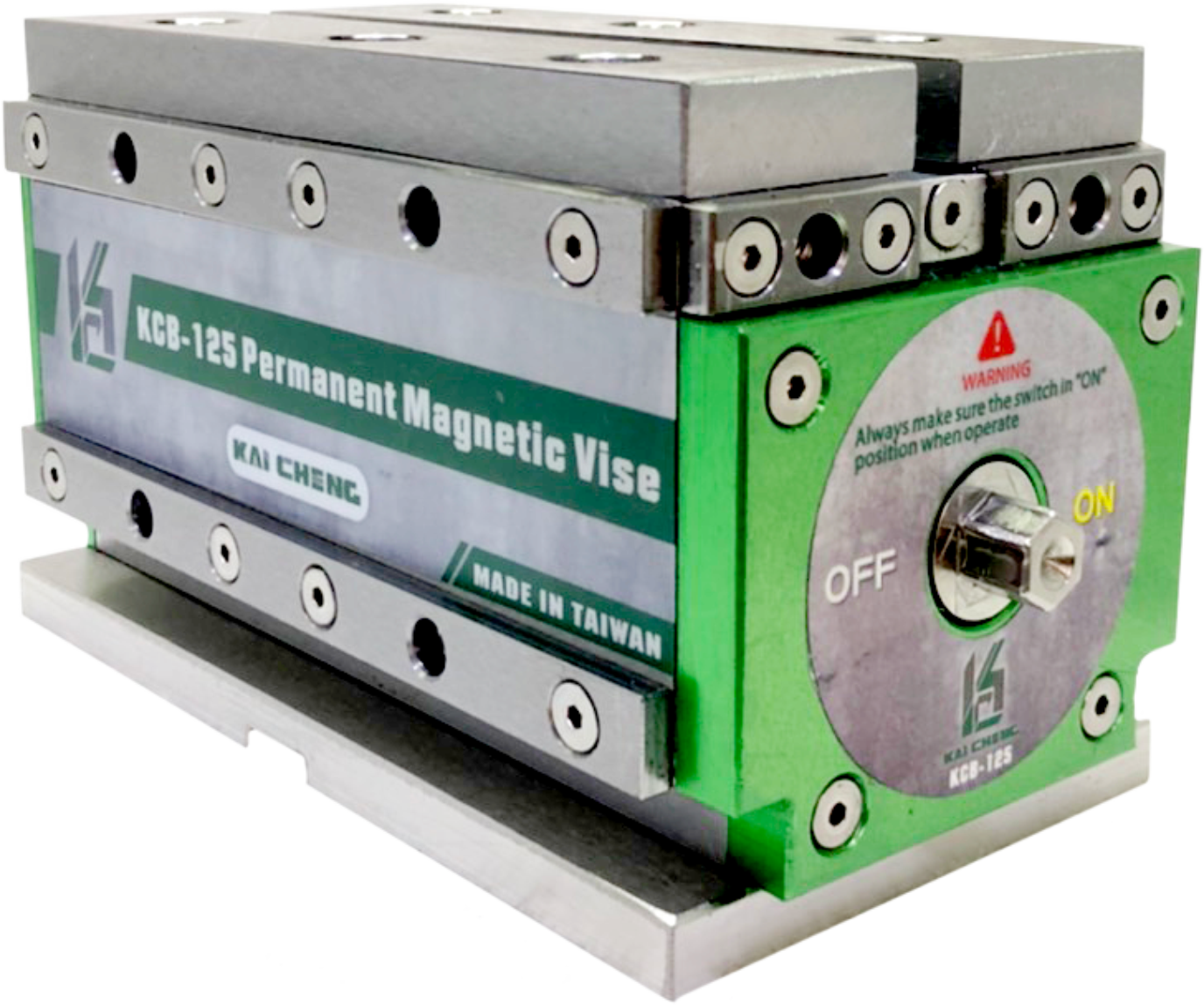

kai cheng co.,ltd

Product Description :

1. The all new model Magnetic Clamping Block KCB Series are a new sense of clamping way for metal working on CNC Machining Center and Milling Machine in quick clamp workpieces.

2. Free to set up position, numbers and distance of Magnetic Clamping Block according to the size of workpiece.

3. The KCB Series including changeable Induction Soft Block. It can be revised the surface to be 100% accuracy on the machine for clamp workpieces. Can be also cutting, drilling, tapping and slotting directly to the Induction Soft Block during machining workpiece. Multi-function of Induction Soft Block, the user can make it by themselves according to workpiece required.

4. Two machining circle for finish workpiece machining, increase a lot of machining efficiency and achieve accuracyrequired.