Theme

Digital Transformation

Green Transformation

HABOR PRECISION INC.

Product Description :

> Applications

Spindle, Linear Motor, Ball Screw, Grinding Liquid, CNC Cutting System, CNC Lathe, Other Machining Center

> Feature

Prevent deterioration of liquid.

Open coil type heat exchanger can prevent the obstruction problem of liquid circulating system.

Advance the speed of process.

Maintain the stability of dielectric fluid, advance the process quality.

Avoid fire risk cause by temperature rise and accumulating of dielectric fluid, advance the working safety.

Reduce the wastage of electrode.

Prevent the spreading of foul odor air, reduce the air pollution.

Easy operation and low noise.

Made of anticorrosive material.

JAINNHER MACHINE CO., LTD.

Product Description :

The aesthetic design of JHT-4010 will convince you, as well as the technology of the fast-moving hydrostatic guideway system.

The 3500rpm built-in spindle, the ability to carry a Ø510mm grinding wheel, and a wheel head axis capable of rotating ±30° for thread grinding are impressive features enabling you to move your manufacturing to a new level.

Jainnher's officially website:www.jainnher.com

Jainnher's Youtube:

https://www.youtube.com/user/GrindingMachineTech/videos

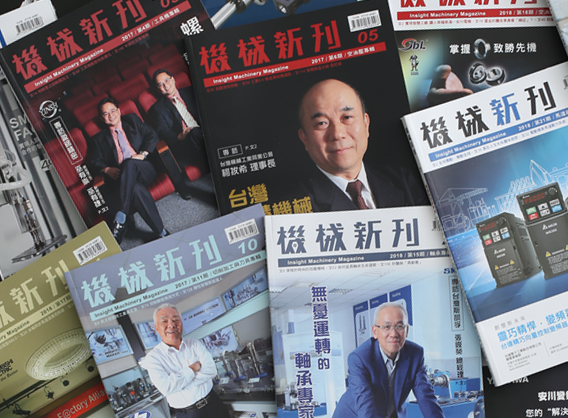

PHD Books Co., Ltd.

Product Description :

機械雜誌的第一品牌

充滿未來性之「機械新刊」具備三點特色:

第一,「選對的主題」。機械新刊每月所挑選的文章,都是對機械產業非常重要的指標性主題,多元化的內容整合,適合讀者每月翻看,汲取新知。

第二,「用對的人」。機械新刊之主編群結合產、官、學、研各界專家菁英,提供最優值的文章和綿密的產業資訊。現在是知識經濟的時代,在知識情商方面,哪一家公司有新產品?哪一家公司有好技術?透過機械新刊廣大的客戶產品資訊,讓您在通路行銷,研發製造各方面都能領先群倫。

第三,「做對的事」。機械新刊的市場定位及聚焦策略,考量傳承與創新之間的平衡,希望雜誌內容能兼顧廣度與深度,除了持續保持專業文章的深度,更重要是與市場貼近,完全掌握市場脈動,同時加入人文的溫度。

2017年起,博士文創事業經營機械新刊,以「廣遞新知,用心規劃」為宗旨,努力建立遍及海內外的讀者群。我們計畫以台灣為中心,向海外拓及讀者群,讓所有華語專業人士,都能翻閱機械新刊,從中獲得想要的資訊。另外,我們要使刊物成為客戶最佳的行銷利器。我們充分瞭解客戶的需求,讓機械新刊成為情資收集的專業平台,展示產品的最佳舞台。機械新刊紙本刊物搭配電商規劃,讓廠商在數位時代,將有更高更長久的曝光。

機械新刊充滿前景,「選對的主題」、「用對的人」、「做對的事」,我們的團隊專業,充滿競爭力,發行人出身機械產業,親身投入用心經營。機械新刊才剛要開始發光發熱,我們有絕對的信心,成為機械雜誌的第一品牌。

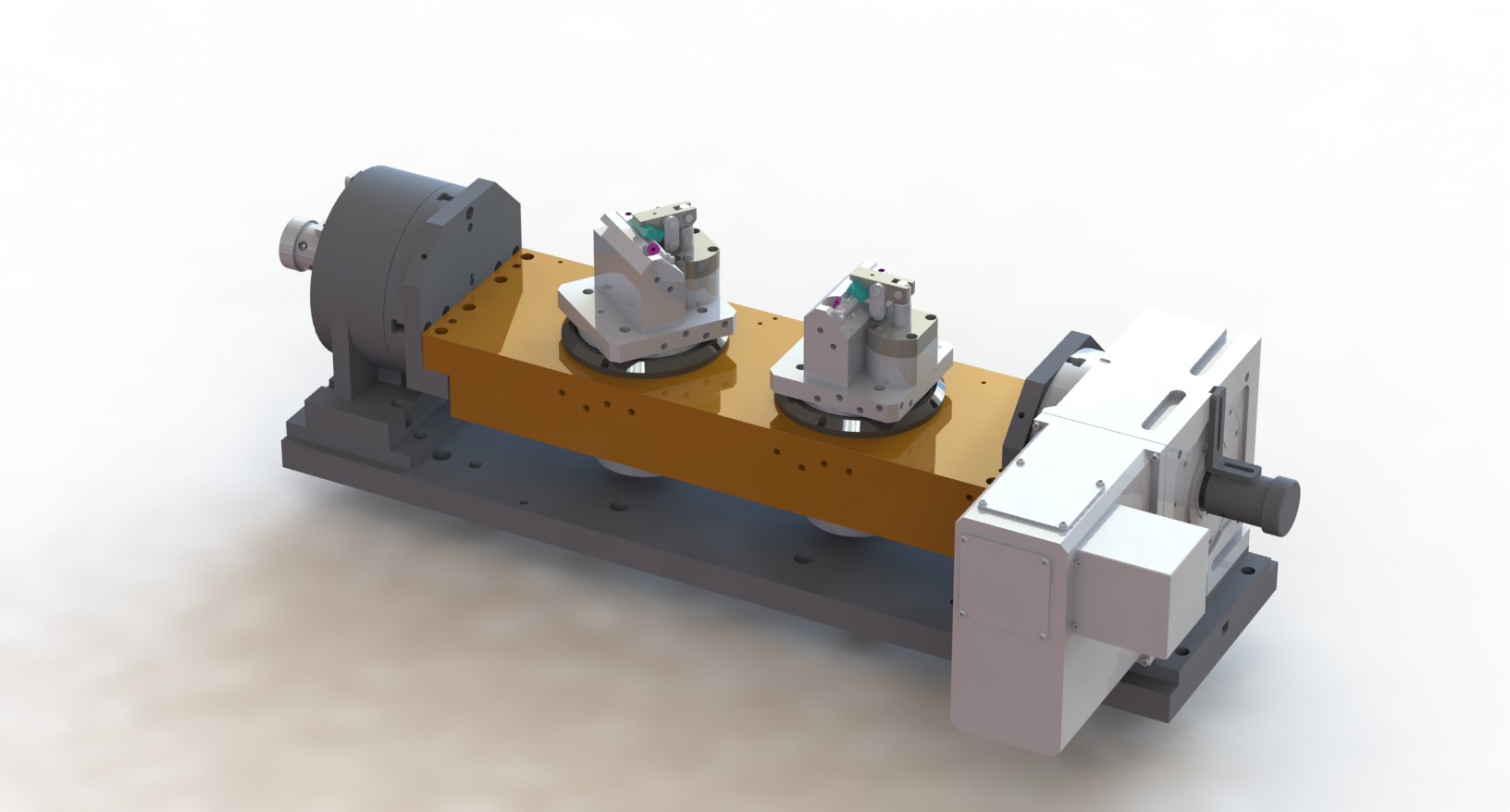

RAISE PRECISION CO., LTD.

Product Description :

The compact, high-resolution MiniCODERs have proven their value for speed and position acquisition in highly dynamic applications. They use their full potential when installation situations with little space require a particularly compact, robust and reliable measuring system. The magnetic measuring systems consist of a ferromagnetic target wheel and a scanning unit. Without dedicated bearings, they are completely wear-free and maintenance-free. The optimised circuit and screening technique, and fully encapsulated electronics ensure reliable operation even in harsh environments.

HISEN ENTEPRISES CO., LTD.

Product Description :

1. Crystal power supply unit, using high-power SiC MOSFET or IGBT.

2. Rotary Table scanning quenching machine, driven by a servo system with ball screws and linear guides, ensuring stable travel speed. Monitoring of each workpiece's processing data ensures consistent output quality (voltage, current, power, frequency, energy, quenching fluid pressure, flow rate, temperature, water level).

3. Quenching fluid cooling system, with water tank and piping made of 304 stainless steel, capable of monitoring water level, pressure, temperature, and flow rate data.

CAMPRO PRECISION MACHINERY CO., LTD.

Product Description :

Campro manufactures a family of Double Column Machining with size up to 5,200 x 3,100 mm travels. The machines offer the highest accuracies of any bridge mill on the market and can machine large parts efficiently with its rigid design. The extended Y-axis has full supported and constructed with a base/bed casting. The PV-XX16 (1,600 mm travels on Y-axis) is one-piece monoblock column structure that is bolted to the bed, delivers rigidity and stability. The PV-xx21 and PV-xx26 have wider door span and bigger machining range, the optional 1,000 mm Z-axis travel is best for attached head requested user.

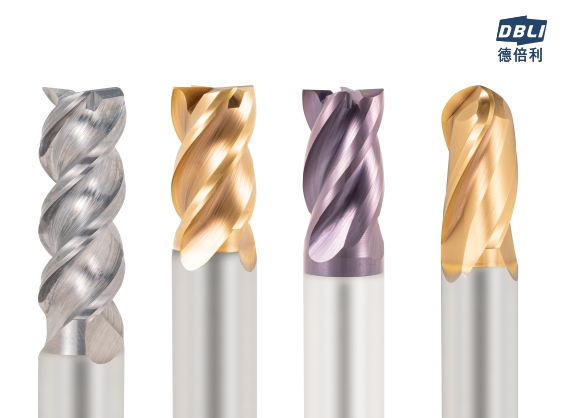

DEEP JET INDUSTRY CO., LTD.

Product Description :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

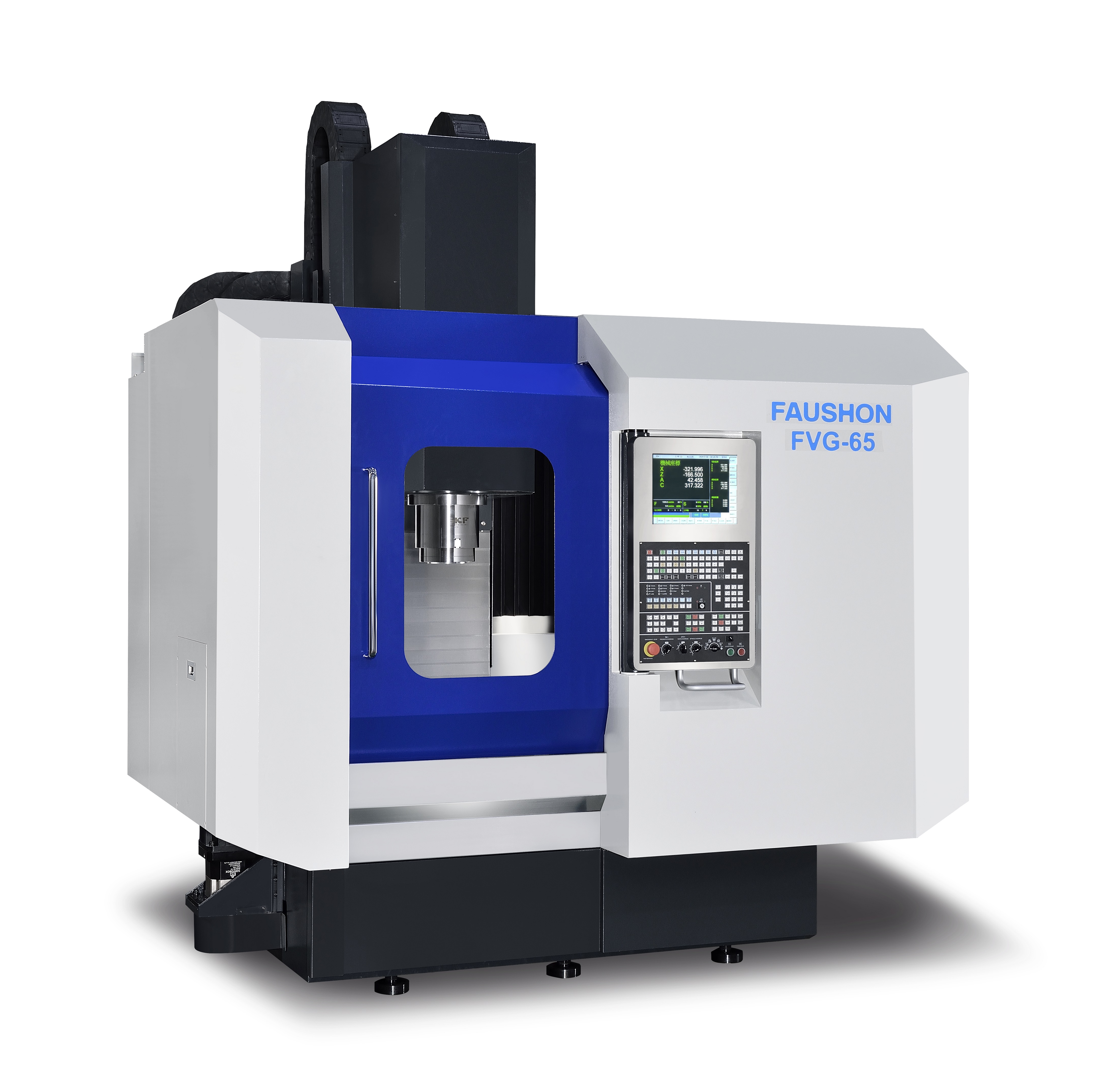

Fulson Industrial Co., Ltd

Product Description :

This model is the culmination of years of careful research and development by Faushon. It boasts a sturdy exterior and robust structure, with all operating handles and active control panels designed to be within the operator's optimal range and most comfortable operating position. This design adheres to ergonomic principles, providing you with higher work efficiency.

With our extensive experience in professional grinder manufacturing, we never compromise on accuracy. We can assure you that our machines offer high precision and reliability. We provide a variety of options and solutions to help address on-site challenges. Our machines are capable of multitasking and offer a high cost-performance ratio in terms of accuracy. The main structure design of the machine undergoes thorough finite element analysis and rigorous review of key components to achieve high precision and reliability.