Theme

Digital Transformation

Green Transformation

WELE MECHATRONIC CO., LTD.

Product Description :

1.立車主軸轉盤以進口交叉滾子軸承設計,確保重負荷的能力及長期的精度壽命。

2. Z軸226 mm方型滑枕搪孔軸採硬軌配Turcite B結構,VTC1612-CW標準行程900mm。

3.底座、立柱、橫樑、工作台等大型鑄件依製造需要,經由最新的3D設計,剛性最佳化,並以

多年經驗訂定有效的退火程序以消除殘餘應力,多年實際應用經驗,確實能達成有效的長期精

度保持性。

4.X、Z軸標準配備採用「雙編碼器」的「雙」半閉環回饋系統,經濟有效的提高各軸的定位精度。

(X、Z軸可選購德國Heidenhain或西班牙FAGOR光學尺)。

5.VTC-CW標準刀庫容量為16P(16儲位),車刀型式及分配數目可依客戶要求處理。

6.主軸箱等關鍵零件係利用自有的「大型臥式鏜孔機」及「大型高精度三次元量測儀(三座標量床)」

確實達成應有的加工精度,確保優良的組裝基礎。

7.承襲歐美先進工具機廠的標準,以嚴格維護的「1.2米x1.2米」高精密度的方形標準平板做為精密

精度的基礎,對各項關鍵零件進行精密鏟花(刮研),使機器的各處結合面和滑動面均能達到正確的

幾何精度,確保機器應有的精度和壽命。

8.搭配高規格的Fanuc數控系統,標準功能包含:15吋彩色液晶螢幕、Fanuc全鍵式操作面板、

2MB記憶容量、Ethernet網路接口、Flash記憶卡插口、剛性攻牙及各種特殊補間(插補)等多項

高規格功能,能經濟有效的滿足各種使用需求。

9.採用的各項配套零組件均經過長期使用驗證,可確保機器長期運行的可靠性。

10.完整的品檢測試流程,搭配先進的自動光學直準儀、雷射干涉儀、球桿檢測儀、線上動平衡儀等

精密檢測儀器,確保出廠的機器都能達到設計的性能和應有的功能。

11.經驗豐富的研發團隊,突破老舊的包袱,協助客戶達成各種特殊需求。

12.兼具經驗和熱誠的服務團隊和完整的服務體系,可以及時有效的讓用戶的機器長保最佳使用狀態。

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. This model combined the functions of turning and milling and can provide customers with more working conditions.

2. Optional C-axis for arbitrary angle spindle positioning and contour control

3. Optional Y-axis live tooling device and end live tooling device can be used for inner and outer diameter turning and milling.

4. Optional:Y-axis side milling device (4-shaft, ER-20), and the distance between each shaft reaches 55mm.

LNS TAIWAN CO., LTD.

Product Description :

The LNS compact solution to automatically load small diameter bar stock into sliding- and fixed headstock lathes from 1 mm up to 12 mm. The GT112 is designed to withstand production processes running at optimum RPMs.

●Integrated 2-in-1 guiding channels to cover the whole range.

●Reliable, hassle-free bar management and loading from 1 ~ 12mm.

●Perfect bar guiding through innovative sectional channel cover.

LIS AUTOMATIC CONTROLLED CO., LTD.

Product Description :

The PJ-20S is a fixed volume medium pressure system without tank designed. Suitable for a general manufacturing environment, designed for Swiss lathes.

-modular PCB, easy to maintenance

-intuitive control panel, easy to operation

-3 sets of M code output

-compact size, saving space

EARTH-CHAIN ENTERPRISE CO., LTD.

Product Description :

1. The all new model Magnetic Clamping Block ECB Series are a new sense of clamping way for metal working on

CNC Machining Center and Milling Machine in quick clamp workpieces.

2. Free to set up position, numbers and distance of Magnetic Clamping Block according to the size of workpiece.

3. The ECB Series including changeable Induction Soft Block. It can be revised the surface to be 100% accuracy on

the machine for clamp workpieces. Can be also cutting, drilling, tapping and slotting directly to the Induction Soft

Block during machining workpiece. Multi-function of Induction Soft Block, the user can make it by themselves

according to workpiece required.

4. Two machining circle for finish workpiece machining, increase a lot of machining efficiency and achieve accuracy

required.

TAIWAN RONG FU INDUSTRIAL CO., LTD.

Product Description :

V:Variable Speed

2F:Spindle Power Down Feed 0.12- 0.18 – 025mm/rev

Gearhead Drill Press with Cross-Slide Table

Rapid Spindle Changes by Quick Select Gear Shift Levers

High Speed Spindle / Quill

Fine Feed Hand wheel for Wide Range Control

Tilting Head Left 90° Right 30°

Suitable for milling and faster drilling setup

GUANG DAR MAGNET INDUSTRIAL LTD.

Product Description :

It provides the strong holding power of an electromagnetic chuck while avoiding heat deformation. This product will not lose its holding force during a sudden power outage, preventing damage to the workpiece and ensuring operator safety. In addition, since it does not require continuous electrical power, it is energy-saving and generates no heat.

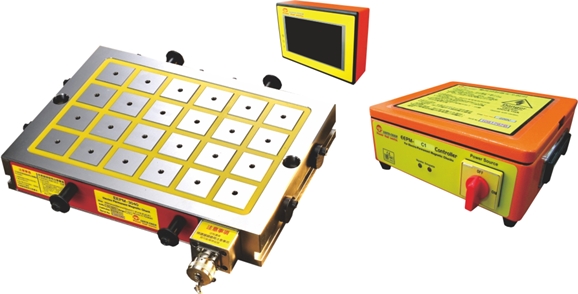

EARTH-CHAIN ENTERPRISE CO., LTD.

Product Description :

1.Suitable for CNC Vertical machining center (Can do 5 sides machining)

2.Suitable for thin, small , medium and large workpiece on varies cuttingmachining.

3.Suitable for thin, small , medium and large workpiece of the drilling and finishing machining.

4.Minimum size of workpiece required as 4 alternate magnetic square poles and above contacts is necessary for

optimum clamping.

5.More functions for cooperate with Induction Block and Spring Block.

SONG GIA INDUSTRIAL CO., LTD.

Product Description :

New technology for polygonal milling, one-piece design, optimised machining efficiency!

●Efficient Polygon Milling: Supports multi-surface machining of 2, 4, 6, 8, and more. A single tool can handle multiple requirements, flexibly adapting to various lathe equipment and speeds.

●Integrated Blade Design: The blade and cutter head are welded as one unit, eliminating the tolerance issues common with traditional tools, enhancing installation ease and cutting precision.

●Optimized Production Efficiency: A more efficient cutting process that reduces machining time, lowers costs, and significantly improves production efficiency.

●Precision Machining Solution: Overcomes the precision degradation problems of ordinary milling cutters, providing stable and high-quality machining results.

Choose SONG GIA's Polygon Unit for Sub Spindle to enhance your machining efficiency and achieve the perfect combination of high efficiency and precision!

SONG GIA provides you with diversified CNC drilling/milling whole series options to meet your various processing demands. We also provide customized design and production according to customers’ different requests.

https://www.songgia.com.tw/en/products/live-tools-for-cnc-lathes/polygon-unit-for-sub-spindle-strb412201

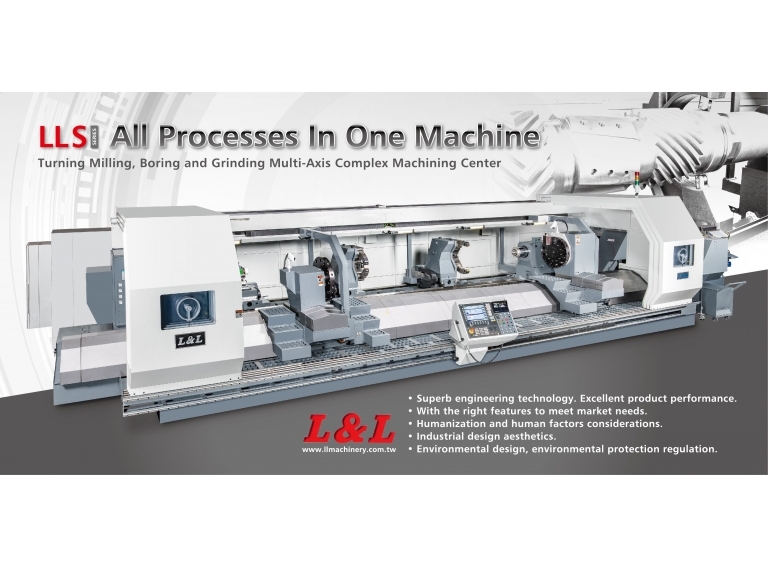

L & L MACHINERY INDUSTRY CO., LTD.

Product Description :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.