Theme

Digital Transformation

Green Transformation

DOWELL CO.,LTD.

Product Description :

ESPRIT® is a high-performance CAM system for CNC programming, optimization and simulation — supporting any class of CNC machine via one common user interface and workflow. Using a digital twin of the CNC to simplify the programming process, ESPRIT delivers edit-free G-code. Combined with ESPRIT's ability to solve workflow challenges with individually tailored automation solutions, ESPRIT is the smart manufacturing solution for any machining application.

With world-class technical support, ESPRIT empowers you to get started quickly and keep your shop running at top efficiency. ESPRIT is the only CAM system you’ll ever need.

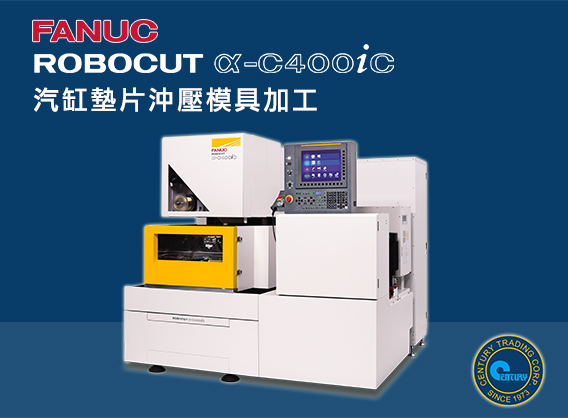

CENTURY TRADING CORPORATION

Product Description :

高性能

● 實現高速、高精度、高品質加工的新機器構造、新放電裝置

● 實現穩定加工的AI熱位移補償功能和各種形狀補償功能

● 實現更廣應用範圍的高精度旋轉軸ROBOCUT CCR

高效率

● 利用高可靠性的自動穿絲AWF3,實現連續無人運轉

● 利用消耗品管理功能和維護嚮導功能,協助日常維護

● 生產及質量信息管理工具ROBOCUT-LINK i

易操作

● 利用發那科先進的CNC和操作嚮導功能,實現優異的操作性

● 利用豐富的加工條件,協助高速、高精度、高品質加工

● 協助加工準備工作的自動化功能

YOKE INDUSTRIAL CORP

Product Description :

•Rotates through 360° and pivot 90°.

•Manufactured from alloy steel, quenched and tempered.

•Manufactured and tested in accordance with EN1677-1.

•Load rated parts are 100% magnaflux crack detected.

•Individual forged parts and cap screw are traceable to Test Certification.

•Bolts are Metric thread (ASME / ANSIB18.3.1M), specification is grade 12.9 alloy socket head screw per DIN EN ISO 4762.

•Individually proof tested to 2.5 times the WLL.

•Fatigue rated to 1.5 times the WLL.

•All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

•Quick and simple assembly, just a tapped hole is required.

TSYR TZUN INDUSTRIAL CO., LTD.

Product Description :

PRODUCT FEATURES

FM-35DL Comes with drilling force control unit for Auto-feeding:

When drill bit is worn out, this unit will drive feeding intermittently or stop feeding. Once feeding becomes difficult while making a hole, please replace a new drill bit or re-sharpen the worn out one in order to protect both drilling tool and machine body from being damaged.

FM-35DL Comes with two intermittent breaking rates for breaking chips:

Choose different feeding rates according to different drill bits and material to perform Auto-feeding operation. This device can break chips intermittently and discharge them while Auto-feeding is processing, so that chips would not roll on drill bit.

Easier to discharge chips.

The machine body is with height adjustment. It’s suitable for both lone and short annular cutters as well as general chuck which is for holding drill with straight handle.

The general chuck is applicable for holding drill which is with straight handle for drilling smaller holes(from 8-13mm).

INNOSERV FA INC. TAICHUNG BRANCH

Product Description :

Standard Equipment

■ 15,000 rpm Direct Drive Spindle (BT40 / HSK-63A)

■ DYPEC - Thermal Compensation

■ Fanuc 0i-MF Plus

■ 15" Touchscreen Display

■ Micro Dynamics HMI

■ Fanuc iHMI

■ 40 Tools

Optional Equipment

□ 20,000 rpm Built-In Spindle (BT40 / HSK-63A)

□ 24,000 rpm Built-In Spindle (HSK-63A)

□ 60 / 90 / 120 Tools

TOP POWER MACHINERY ENTERPRISE CO.

Product Description :

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

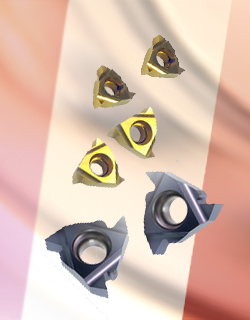

TAIHO TOOL MFG. CO., LTD.

Product Description :

The blade design that emphasizes cutting force and the unequal lead groove shape promote chip discharge and realize high-quality threading.

The lineup includes screw type for blind holes and through holes, and features that chips are discharged upwards.

The tip sample is for through holes, and the characteristic is that the chips are discharged downward.

There are two types of pipe specimens: parallel thread for mechanical bonding and tapered thread for tightness.