Theme

Digital Transformation

Green Transformation

HOLDING ELECTRIC CO., LTD.

Product Description :

The magnetic grinding machine is an innovative product of Holding Electric, and has won invention patents from many countries in the world

This patented device generates a magnetic field that motivates magnetized pins to bounce rapidly and to grind parts

Features

1.For High Precision

2.Grind Every Corner:

Effect

1.Deburring

2.Polishing

MANFORD MACHINERY CO., LTD.

Product Description :

VX-600 5-Axis Machining Center is designed for multiaxes machining of small and large series of complex 5-side workpieces. With swiveling head and rotary table, VX-series is able to do simultaneous 5 axes machining with high accuracy.

High proformance swiveling head, tilting angle from -120 ~ +30 equipped with 15,000rpm built-in spindle.

VX-600/VX-600T is with an enbedded Ø 630mm diameter rotary table. Any complex workpiece can be accomplished with a single setup.

SHAN HUA PLASTIC INDUSTRIAL CO., LTD.

Product Description :

PU pneumatic tubing is commonly used in machine tools and industrial automation equipment for pneumatic piping and compressed air systems.

The tubing offers high flexibility and good abrasion resistance, making it suitable for routing in applications requiring bending or movement of machine components.

Both PU Ester and PU Ether materials are available, along with multiple sizes and color options for easier installation and air line identification.

• PU Ester: Suitable for general industrial pneumatic systems

• PU Ether: Suitable for high-humidity environments or applications requiring hydrolysis resistance

SHIN-YAIN INDUSTRIAL CO., LTD.

Product Description :

PCK rough boring head is designed with triangle curve form with boring head for one-piece structure. This design provides shorter length and perfect connection. It creates stable machining capacity successfully and improves the rigidity, precision and anti-vibration during machining.

JAR HON MACHINERY CO., LTD.

Product Description :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic machine so a person can operate many machines.

3.Gear-pitch type auto. tapping will get a precise & accurate thread for finished workpiece.

4.It can option to add inverter or use servo motor to control the spindle speed.

4. Especially suitable for light workpiece.

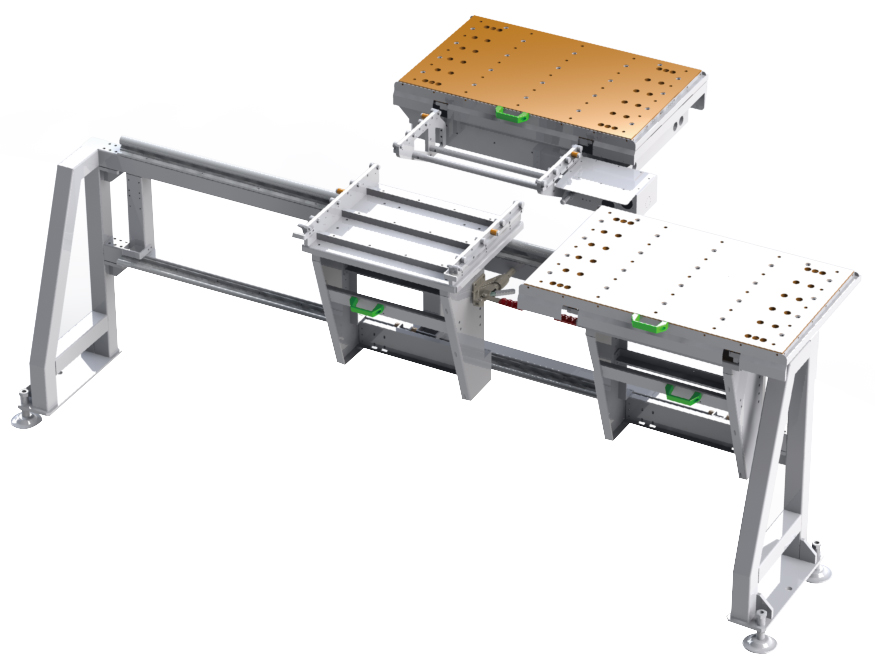

TAIWAN 3AXLE TECHNOLOGY CO., LTD

Product Description :

. Processing size: 1300*900mm.

. Metal cutting configuration with Raycus fiber laser, laser wattage 1000W

. Non-metal cutting configuration 320W Co2 laser tube + professional thick plate cutting head

. Professional cutting system, "one-key switch button" on the machine, can easily switch between metal cutting function and non-metal cutting function.

. This equipment is specially designed for cutting a variety of materials, whether metallic or non-metallic.

. We combine the top-standard Co2 non-metal laser cutting machine configuration with the most popular fiber laser cutting configuration currently used in one machine

. Metal cutting head, 10mm focus Z axis direction adjustment, wide cutting range; excellent and stable beam quality, perfect water-cooled structure, advanced dustproof design, effectively avoid dust intrusion.

. Co2 non-metallic laser cutting performance can perform acrylic cutting with a thickness of 30mm. Because the laser head of this model is specially designed, it shows a bright clean surface without ripples after the acrylic cutting of thick plates.

. Optical fiber laser metal cutting performance Stainless steel can be perfectly cut to 3mm without post-processing. For carbon steel, it can also be cut to a degree of 6~8mm. It is the same grade for professional cutting applications.

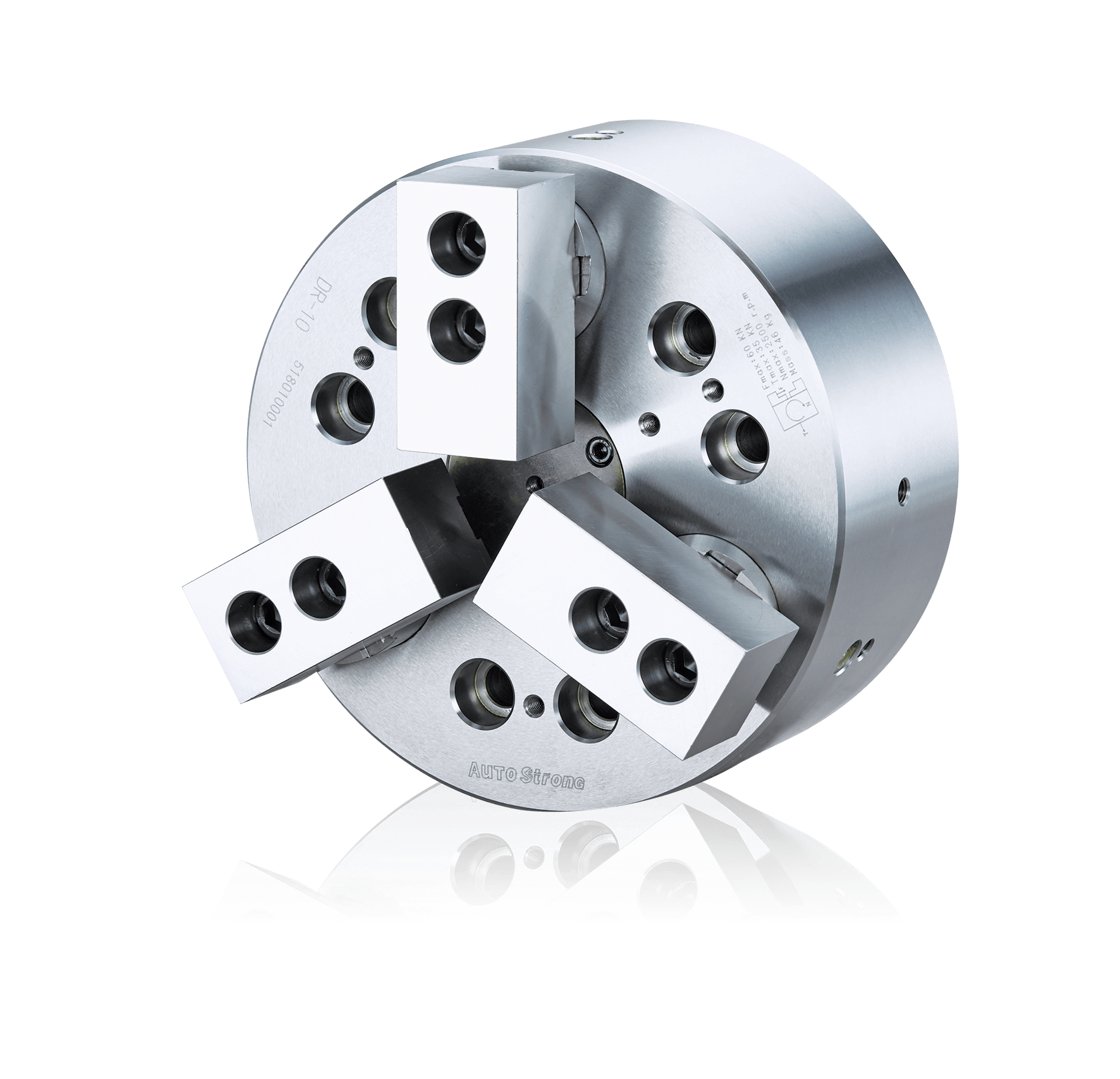

DI CHUN IRON WORK CO., LTD.

Product Description :

Drawdown power chuck feature of radial clamping will lead to almost no workpiece uplifting displacement; for machining casting and forging part:

1. For the clamped workpiece is oppressed to the surface, chucks are suitable for heavy machining.

2. Chuck Actuators with the cylindrical structure is durable and ensures high clamping repeatability.

3. Accurate self-centering and pull back features are adequate or precise length control machining requirements.