Theme

Digital Transformation

Green Transformation

JARNG YEONG ENTERPRISE CO., LTD.

Product Description :

1. External auto loading/unloading SPM

2. Its feeding capabilities are O.Dφ6~φ35 mm, max length 40mm.

3. Its feeding mechanism is placed outside of machine to keep mechanism from chips and oil stain.

4. Adjustable guideway is suitable for round/hex shape workpiece alone with rotary cylinder and fixture, which can make hex material positioning in short time.

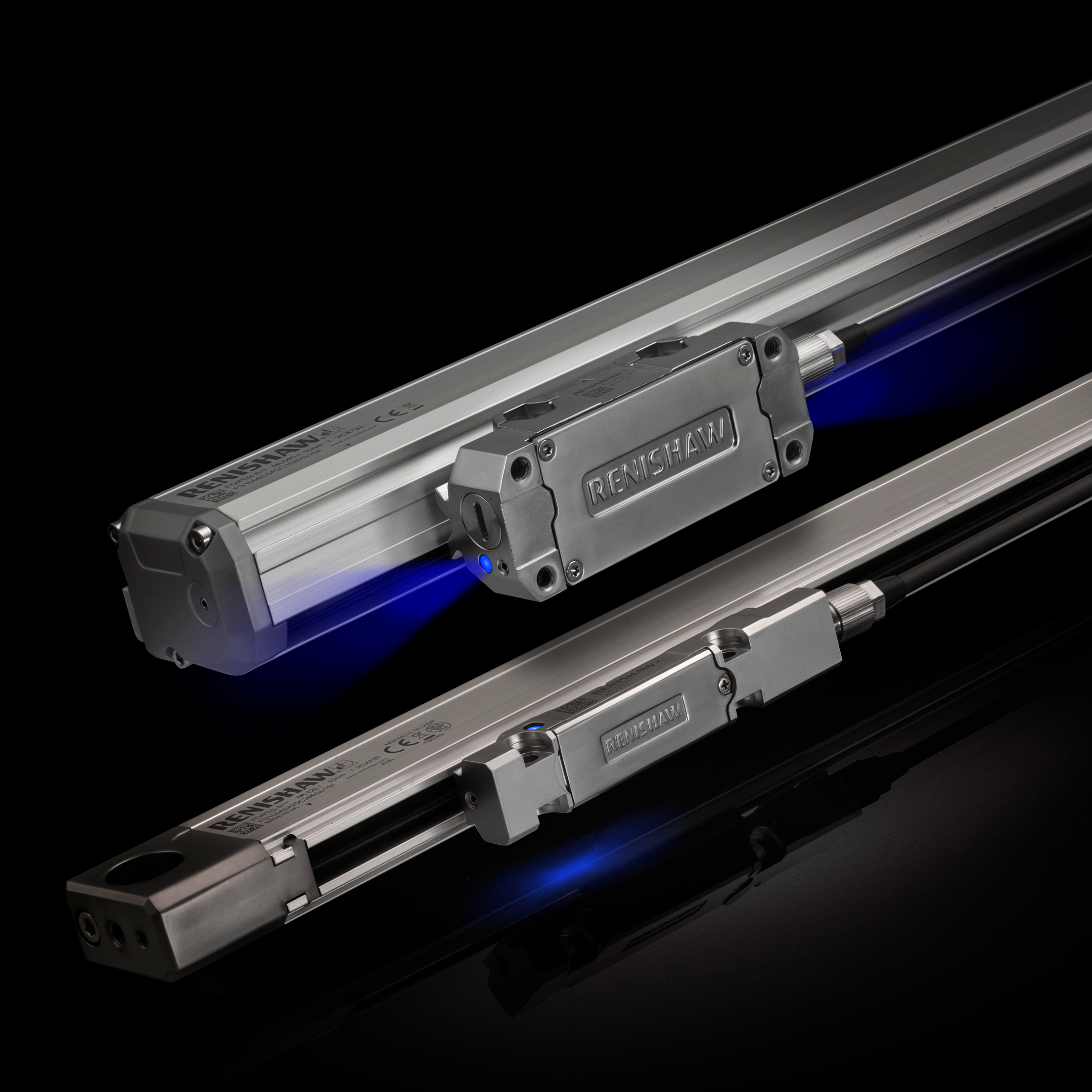

RENISHAW (TAIWAN) INC.

Product Description :

Renishaw 提Renishaw 提供各式各樣的封閉式光學尺,也稱為密封式光學尺。歡迎瞭解我們的絕對式量測技術搭配強大的密封及非接觸設計,如何在工具機等惡劣環境中協助提升精密製造。

在最惡劣的環境中運作的位置光學尺

FORTiS 線性光學尺採用 Renishaw 深獲業界肯定的 RESOLUTE™ 絕對式光學尺技術,以堅固的封閉式設計在最惡劣環境中提供高效能量測,展現超越傳統系統的重大效益:

• 非接觸式設計 - 無機械磨損並延長使用壽命。

• 降低遲滯 - 更順暢的回饋和更好的動態效能。

• 突破性的讀頭設計 - 調諧質量阻尼器協助實現領先同類產品的抗振效果(高達 30 g)。

• 符合 IP64 標準的卓越密封等級 - 優異的密封技術可加強保護,避免液體及固體碎屑污染。

• 採用專利方法裝設的 LED - 完整 LED 訊號強度指示器,可進行簡單快速的安裝和設定。

• 減少洩漏空氣可降低淨化空氣用量。

我們也提供兩種不同的鋁擠型尺寸以配合空間需求:FORTiS-S™ 標準寬度 (37 mm) 及 FORTiS-N™ 精細型 (18 mm)。FORTiS 線性光學尺也設計為可直接取代傳統的玻璃線性光學尺,提供完全相容的安裝、外型及功能,可於現有機台配置快速輕鬆地進行安裝。兩種尺寸均提供功能安全 (FS) 版本。

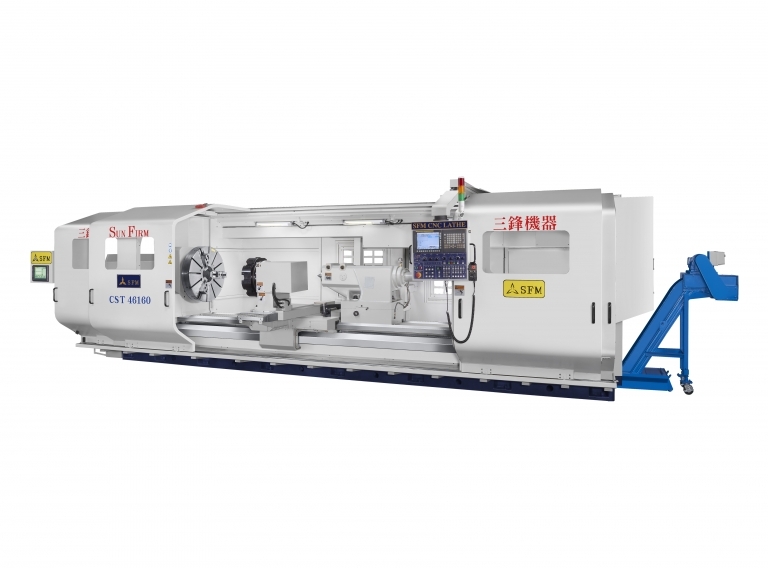

SUN FIRM MACHINERY IND. CO., LTD.

Product Description :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

CST-46160 is a very efficient machine that can meet all kind of requirements for multi-task and complex machining, shorten processing time and reduce part clamping errors. It can be installed with FANUC, SIEMENS, FAGOR control devices, satisfying customer's needs and becoming more user-friendly.

HOLDING ELECTRIC CO., LTD.

Product Description :

Stationary Demagnetizers is the latest product of Holding Electronics in 2020.

It is designed to solve the demagnetizing problems for heavy, large, and long workpieces which are difficult to be moved on the conventional demagnetizer

Features

One-key demagnetization. No need to move workpieces during demagnetization.

Demagnetization can be complete in about 10~15 seconds.

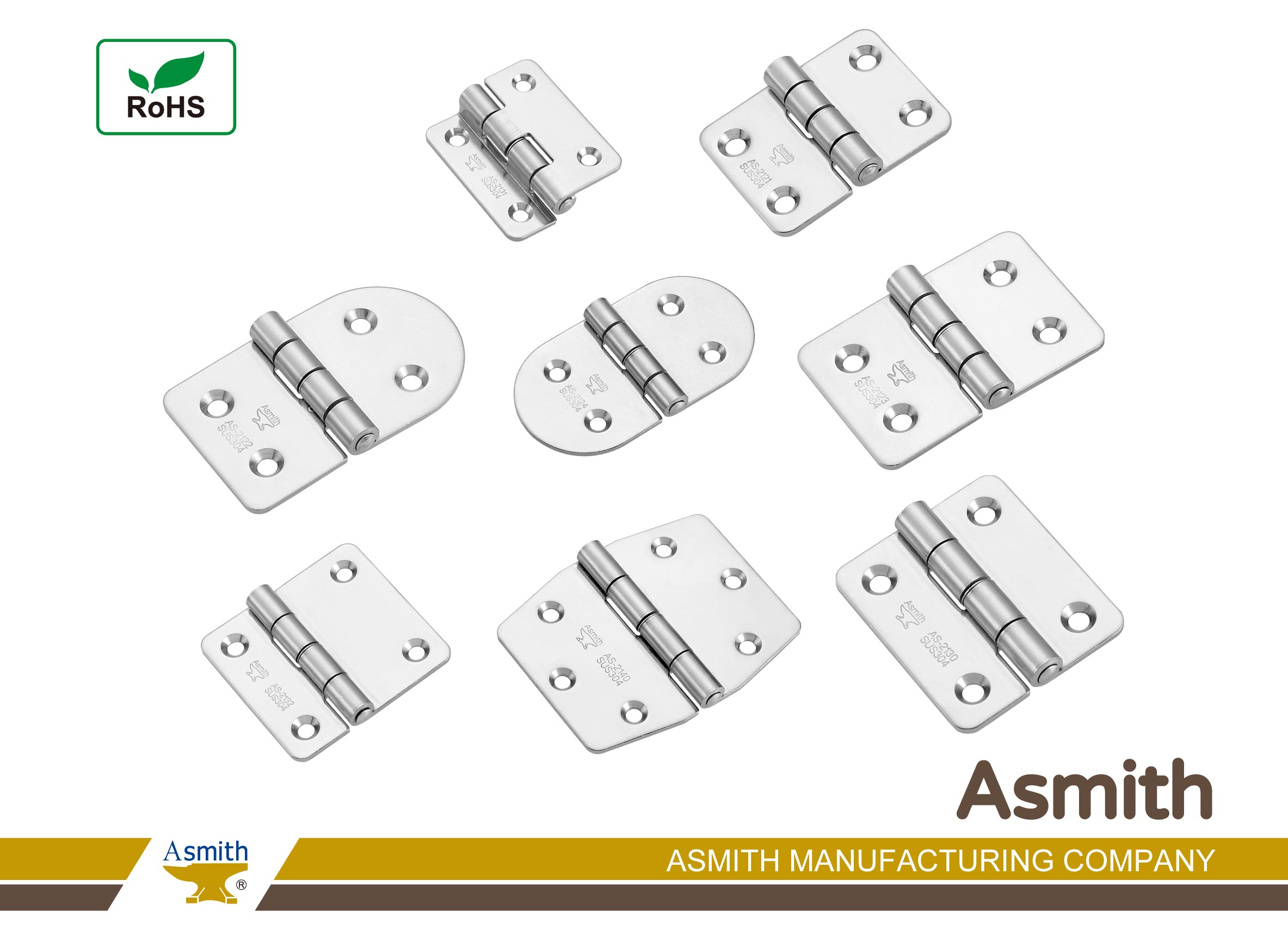

ASMITH MANUFACTURING COMPANY

Product Description :

AS-21 Series

Micro-damping friction butt hinge allows the door panel to be fixed at any position when opened left or right. Features stepless self-positioning control. Counterbore hole design, suitable for countersunk screws.

More info:https://www.asmith.com.tw/en/products/Hinge/Butt/AS-21

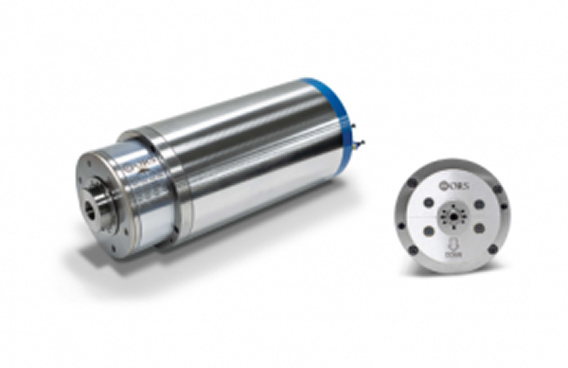

ORS KOREA

Product Description :

The Magnetic Bearing Spindle uses electromagnetic force to support the shaft in a fully non-contact structure. Leveraging ORSKOREA’s advanced high-speed and precision spindle design capabilities, magnetic bearing systems can be applied and tailored according to specific operating conditions. With no mechanical contact, wear is eliminated, making it suitable for ultra-high-speed operation and precision control applications in semiconductor, aerospace, and other advanced industrial sectors.

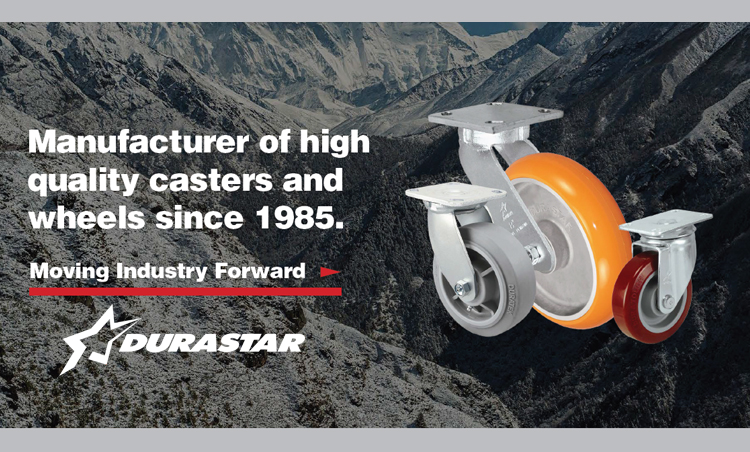

Durastar Casters and Wheels

Product Description :

自1985年起,美國Durastar鉅國腳輪擁有超過30年的高品質腳輪製造與PU灌注經驗,是專業的腳輪製造商,具有多樣化的產品生產線,供應北美及亞太區域各式腳輪、輪子、油壓拖板車輪、堆高機輪與客製化PU灌注。我們生產高品質的聚氨酯優力膠PU輪適用於各種行業,應用範圍重至航太工業、輕至小型推車,鉅國腳輪都能滿足您的各式腳輪與PU產品需求。 鉅國腳輪所製造的腳輪及各式優力膠PU產品以高品質與高CP著稱,省力穩定且耐用,客戶遍布世界各地,諸如美國FedEx聯邦快遞、美國甘迺迪機場行李推車、日本Bishamon毘沙門、台灣美光科技及漢翔航空工業等皆使用我們的產品。

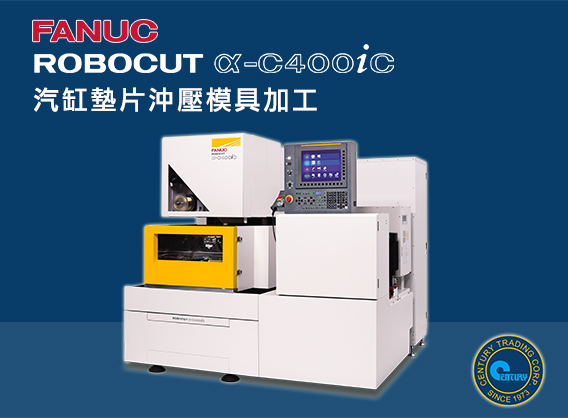

CENTURY TRADING CORPORATION

Product Description :

高性能

● 實現高速、高精度、高品質加工的新機器構造、新放電裝置

● 實現穩定加工的AI熱位移補償功能和各種形狀補償功能

● 實現更廣應用範圍的高精度旋轉軸ROBOCUT CCR

高效率

● 利用高可靠性的自動穿絲AWF3,實現連續無人運轉

● 利用消耗品管理功能和維護嚮導功能,協助日常維護

● 生產及質量信息管理工具ROBOCUT-LINK i

易操作

● 利用發那科先進的CNC和操作嚮導功能,實現優異的操作性

● 利用豐富的加工條件,協助高速、高精度、高品質加工

● 協助加工準備工作的自動化功能