Theme

Digital Transformation

Green Transformation

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

The Manual Pulse Generator Engraving Handwheel by YEU-LIAN is designed for CNC operation panels, enhancing applicability through metalworking materials. It protects against dust, water, and oil, with an optical rotation, non-contact detection structure ensuring no vibration affects signal output. The encoder withstands 3 million cycles maintaining high precision, and features anti-static design, wide voltage range (DC5V to 24V), high reliability, and strong consistency. It's easy to install, suitable for various automation equipment, and CNC systems, ideal for CNC MPG pendant controllers and CNC operation panels.

SCN MACHINERY CO., LTD

Product Description :

深絞(深抽)成型油壓機 - SYT series<br />

<br />

Tonnage: 100 - 3000 ton<br />

Bolster Area: 800 x 700 - 4500 x 3000 mm<br />

<br />

SYT 深絞成型機 - 機身採用高張力,中鋼一級鋼板,頂座,底座,形成門型機架精加工.90°導軌八面滑合設計,滑塊上下運動,導向性好,精度好,強度高,滑合面自潤銅襯材質,導軌高週波硬化,研磨加工,永保精度不變.<br />

油壓動力系統,設計於機台後方採用管路板式集積回路設計,並附冷卻系統,效率能完全發揮,保養簡潔。<br />

油溫超過設定55度,馬達自動停止運轉,並發出警報聲,提醒操作者冷卻水異常,確保油封使用壽命<br />

配備獨立式操作控面板,吋動,下降.慢速加壓.快速上昇.等操作按鈕,前方附有緊急停止按鈕,操作容易安全,由壓力表設定出力大小、行程位置調整於微動開關設定。<br />

<br />

符合ISO9001:2015認證

HEIDENHAIN CO., LTD. (TAIWAN)

Product Description :

Angle encoders for rotary and tilting axes are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Because angle encoder measure angular motion of the axis directly and immediately. Mechanical transfer elements therefore have no influence on position measurement, both kinematics errors and the influences of forces are measured by the angle encoder and considered in the position control loop. This can eliminate a number of potential error sources: Gear errors, reversal error, errors due to deformation of the drive mechanics by machining forces.

QUASER MACHINE TOOLS, INC.

Product Description :

Flexible Manufacturing System provides a solution for

massive production or high mix low volume. Simple installation

design helps users to increase productivity in a short time.

The intelligent Automatic Pallet Change Cell has a compact

footprint design with, 6 or 8 pallet options. APC can be field

retrofitted even if the machine is settled months or years ago.

Robotic Tool Magazine Cell is a perfect match for lights out machining.

It also has a small footprint to maximize the user’s facility space.

6 manual loading pockets reduce tooling loading time efficiently.

Lanza International Co., Ltd.

Product Description :

Global Supply Chain Reshaping|Taiwan’s Hardware Industry Moves Toward Intelligence and Sustainability

In an era of global supply chain restructuring and accelerated smart manufacturing transformation, Taiwan has emerged as a vital hub in the global hardware industry—powered by its outstanding precision manufacturing capabilities, flexible supply chain system, and innovative R&D strength.

The 2025 Taiwan International Tools & Hardware Expo x International Hardware Expo Taiwan (TiTE x IHT) will be grandly held from October 21 to 23 at the newly completed Taichung International Convention and Exhibition Center.

With "TEAM TAIWAN" as its core theme, this year’s edition brings together Taiwan’s industrial cluster strengths and global sourcing demands to create a one-stop sourcing platform for international buyers, reinforcing Taiwan’s role as a central force in the global hardware supply chain.

JINN FA MACHINE INDUSTRIAL CO., LTD.

Product Description :

Max. turning diameter 32mm ~ 42mm.<br />

<br />

Max eight axes simultaneously movement (X1/Y1/Z1/X2/Y2/Z2/C1/C2).<br />

<br />

Sub tooling system can make eccentric drilling, milling and grooving function.<br />

<br />

Side drilling can be converted to end drilling (six for front & six for back).<br />

<br />

Rigid structure with powerful lives tools brings you stable and versatile machining performance.

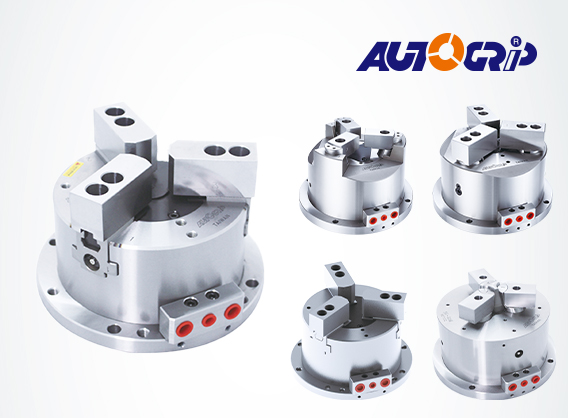

AUTOGRIP MACHINERY CO., LTD.

Product Description :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

FOCUS CNC CO., LTD.

Product Description :

FNL-220 series turn-mill machine is integrated with innovative feature 30-degree slant bed, roller type linear guideways and 60-degree compound Y axis. Roller type linear guideways ensure high accuracy performance during high speed machining and provide 30% stronger rigidity than ball type guideways. With the biggest Y axis travel ±55mm in same class, high torque live tooling and full C axis for main and sub-spindle.

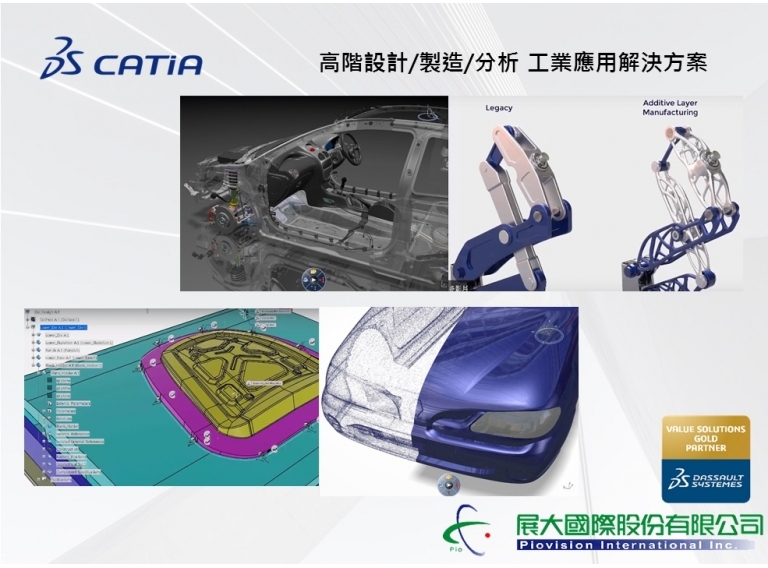

PIOVISION INTERNATIONAL INC.

Product Description :

CATIA強化您的開發與設計工作以全面符合客戶的高度要求,並提供3DEXPERIENCE平台,讓使用者可以簡易<br />

<br />

完成圖檔管理的工作。根據不同的產業別與需求,分別提供適合不同的模組套裝,例如:機械設計套組、逆向工程套<br />

<br />

組、模具設計套組、外型設計與自由曲面造型套組、工程分析套組...等。<br />

<br />

CATIA擁有強大曲面設計、逆向工程等功能,強化企業開發與設計工作效能,廣泛適用於航太、汽車、機械、電子等<br />

<br />

產業,可支援OEM到供應鏈製造商等。具備直觀的3D建模和模擬功能,同時深具包容性的產品開發平台,讓現有<br />

<br />

流程和工具輕鬆集成,採用一體化思路,讓您從設計到製造整合於一平台完成。

CAPTAIN SCIENCE CORPORATION

Product Description :

The Rotoclear C2 is a high-durability camera system designed for installation inside machine tools.

Featuring a self-cleaning lens and 4K high-resolution recording, it delivers clear, detailed views even under challenging conditions with chips, coolant, and high pressure.

It can be mounted on the top (top view), side (side view), or directly on the spindle head (tool view), providing completely new visual perspectives of the machining process.

With support for HDMI, USB, Ethernet, and RTSP/TCP-IP interfaces, the system enables real-time image capture, storage, and sharing — making it an ideal tool for process monitoring, image analysis, and smart manufacturing.