Theme

Digital Transformation

Green Transformation

LNS TAIWAN CO., LTD.

Product Description :

The LNS economical bar feed solution to automatically load bar stock into sliding headstock lathes. The GT326 bar feeder is designed to withstand production process running at optimum RPMs. High guiding quality, low noise and effective vibration-dampening are guaranteed through molded polyurethane guiding channels.

●The two-position front stabilizer with v-shaped guiding elements dampens residual vibrations between the barfeeder and the lathe.

●The user- friendly remote control combined with HMI allows an easy setting and interface. (Option)

●Simple and fast conversion thanks to a centrally controlled, manual setting using an adjusting lever. (Option)

YEU-LIAN ELECTRONICS CO., LTD.

Product Description :

We customize CNC Operation Panel matched with FANUC 0i-MD, FANUC 0i-TD CNC system, SIEMENS 828D CNC system PP72/48 and MITSUBISHI M70, M80 and many other CNC control systems. Our operation panel can be flexibly adjusted the design of the machine and offer multi-functional elements such as membrane, acrylic, crystal, laser engrave, silicon protection. Furthermore, customized I/O design to your requirements. In addition to extending the flexibility, it also enhanced the product's quality and endurance.

WEXTEN PRECISE INDUSTRIES CO., LTD.

Product Description :

■ Maintained the constant oil temperature in order to prevent process-ing precision-losing.

■ Kept oil viscosity and avoid oil deterioration to stable spindle working.

■ With the temperature control panel to avoid thermal expansion.

■ Built-in failure-detection system that connects to control panel in order to warn users and prevent further damage to machine.

■ Filling high-efficiency environmental refrigerant, without pollution.

KING NICE TECH.CO., LTD.

Product Description :

▎Liquid filter purification, easy removal.

▎ Patented technology - easily correspond with liquid,water-soluble and Pure-oil Auto.

▎ Processing can easily recover swarf and sediment without stopping.

▎ The highest filtration accuracy can correspond to 5 nano.

▎ Solve the problem of long-term deposit on CNC water tanks such as iron chips,aluminum powder,fine sediment,etc.after machining.

▎ Widely used in metal cutting, aluminum machining,grinding process,engineering plastics, etc.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

Product Description :

1.A circular tube modifies an interior angle and an external angle at one time with fastness and precision.

2. It's simple and fast to switch the knife because of easy to buy the insert disc in the market.

3. Two-stage of feeding knife, and the idle stroke is smooth. It's available for adjusting the operation stroke according to the cutting volume.

4. There are automatic and manual functions, which are convenient for adjusting the machine.

5. Special automatic positioning device, which can automatically position, feed and chamfer, and fine-tune the length tolerance.

6. Oil mist cooling and lubricating system promotes insert life, and no chips will stay.

7. There is a pause switch at the final point so as to assure the flat plane and the accurate right angle of the work piece.

8. The axle head with phosphor & copper bushing can prolong the life.

9. It can be option the lifting rack to use with this machine.

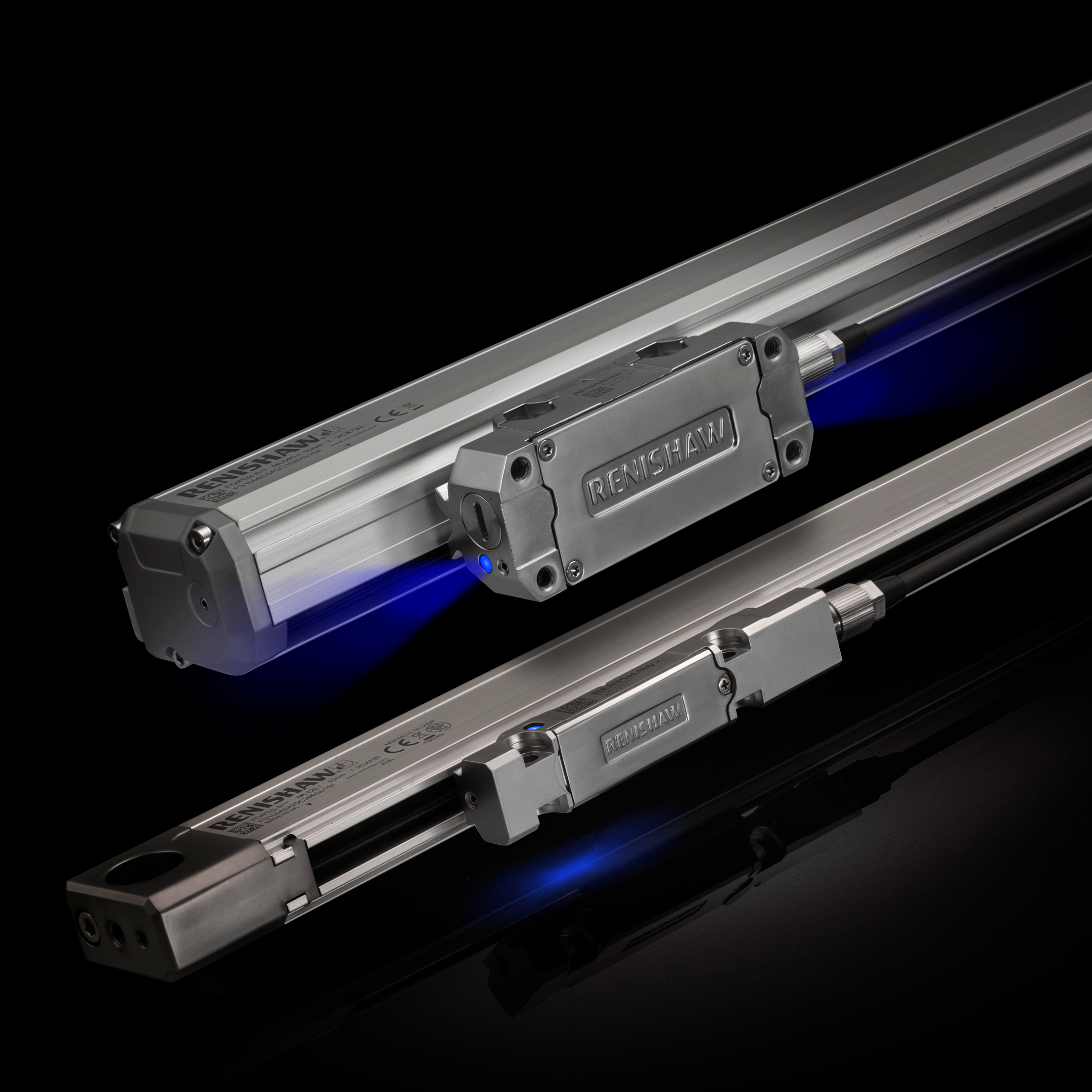

RENISHAW (TAIWAN) INC.

Product Description :

Renishaw 提Renishaw 提供各式各樣的封閉式光學尺,也稱為密封式光學尺。歡迎瞭解我們的絕對式量測技術搭配強大的密封及非接觸設計,如何在工具機等惡劣環境中協助提升精密製造。

在最惡劣的環境中運作的位置光學尺

FORTiS 線性光學尺採用 Renishaw 深獲業界肯定的 RESOLUTE™ 絕對式光學尺技術,以堅固的封閉式設計在最惡劣環境中提供高效能量測,展現超越傳統系統的重大效益:

• 非接觸式設計 - 無機械磨損並延長使用壽命。

• 降低遲滯 - 更順暢的回饋和更好的動態效能。

• 突破性的讀頭設計 - 調諧質量阻尼器協助實現領先同類產品的抗振效果(高達 30 g)。

• 符合 IP64 標準的卓越密封等級 - 優異的密封技術可加強保護,避免液體及固體碎屑污染。

• 採用專利方法裝設的 LED - 完整 LED 訊號強度指示器,可進行簡單快速的安裝和設定。

• 減少洩漏空氣可降低淨化空氣用量。

我們也提供兩種不同的鋁擠型尺寸以配合空間需求:FORTiS-S™ 標準寬度 (37 mm) 及 FORTiS-N™ 精細型 (18 mm)。FORTiS 線性光學尺也設計為可直接取代傳統的玻璃線性光學尺,提供完全相容的安裝、外型及功能,可於現有機台配置快速輕鬆地進行安裝。兩種尺寸均提供功能安全 (FS) 版本。

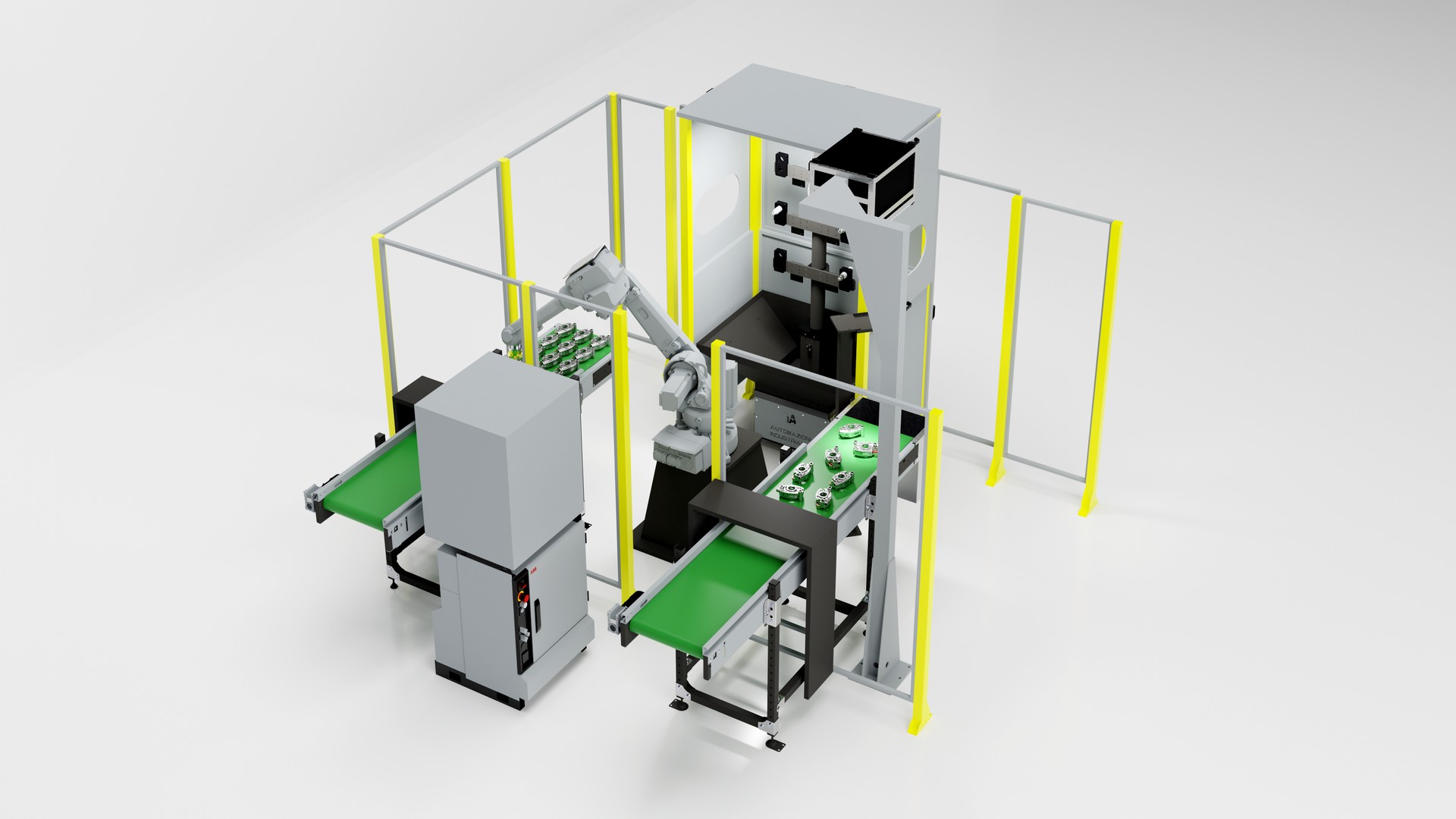

AUTOMAZIONI INDUSTRIALI SRL

Product Description :

Our deburring robot cells are designed to automatically deburr workpieces using different tools within the same cell.

-deburring and finishing tool station

- reduced cycle times

-high-speed deburring tools

-possibility of deburring different types of surfaces

-guaranteed homogeneous finishing

This makes it possible to work on different types of surfaces with speed and precision, guaranteeing the highest quality.

The raw parts are fed via one or more conveyor belts suitable for picking up the parts with our DRS robot-guided vision system.

Depending on the degree of finishing, the robot cell can consist of a high-speed deburring unit with a milling tool and a compensated file tool, both of which are suitable for the robot, a power tool with a brush for possible passage through holes, a pneumatic lubrication and air filtering unit and a collection tank for swarfs.